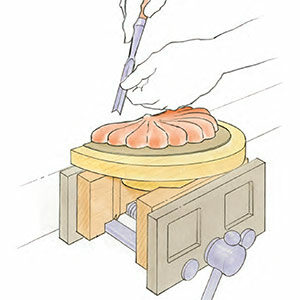

Synopsis: Gareth Neal’s furniture is rectilinear outside, but hundreds of kerfs in the surface reveal hidden classical furniture shapes within. A computer modeling program first inspired Gareth Neal to try his shape-within-a-shape furniture designs. Learn how he incorporates CNC machines as part of his workflow when making these interesting pieces.

Gareth Neal explains that he was using a computer modeling program, working with different layers in the same drawing, “when suddenly by accident I saw one shape inside another, overlaid with all these lines.” Inspired, he was soon out in the shop trying to duplicate what he’d seen on the screen. For his first pair of tables he did all the kerfing himself at the tablesaw, raising or lowering the blade for each new cut. It took five days to make the legs for two tables. Since then he’s sent parts out to be kerfed in shops with CNC machines. Neal’s own workshop is in London’s East End, but he’s worked with CNC operators in various parts of England. “I look at CNC as just another tool,” he says. “There’s good and bad CNC work, just as there’s good and bad hand carving.” Carving is what first drew him into the field, and he still enjoys it. “At home in the evening,” he says, “I’ll whittle a spoon, carving with an ax and a gouge.”

For the full article, download the PDF below:

Log in or create an account to post a comment.

Sign up Log in