Peen your tenons for easier assembly and a locked joint

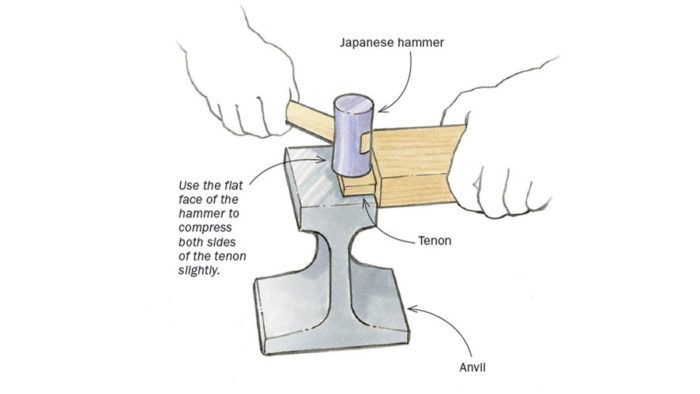

Compressing tenons with a hammer and vise makes assembly easier and prevents the mortise from scraping off all the glue during assembly, which can starve the joint. I learned this amazing technique from my friend and mentor, Steve White, who studied with a master joiner from Japan. You’ll need a Japanese hammer ($30 at HidaTool.com for a 13-oz. version with one flat and one crowned face) and a small steel anvil (inexpensive used or new).

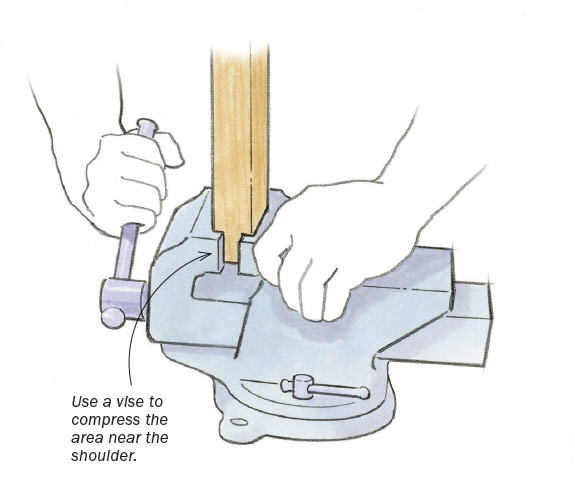

Cut the mortise first, then the tenon. Make the fit a bit snug, so it requires some pressure to get the joint together. Next, use the flat side of the hammer to peen (slightly compress) both sides of the tenon, resting it on the anvil and making sure not to hit the shoulder. Then use the flat jaws of a metal or hardwood vise (I prefer metal) to squeeze the part of the tenon next to the shoulder. The tenon should slide in and out fairly easily.

Having planned out your clamping beforehand with a dry-fit, use a brush to apply glue to both mortise and tenon. Slide the joint together (it will be easy now) and close it tight with clamps. Moisture from the glue will swell the tenon back to its original size for a tremendously strong joint. One note of caution: If the mortise walls are thin, clamp the sides of the joint to stop it from expanding outward.

—Todd Bradlee, Bishop, Calif.

Drawings: Dan Thornton

Issue #263 Sep/Oct 2017

Fine Woodworking Recommended Products

Suizan Japanese Pull Saw

Leigh D4R Pro

Leigh Super 18 Jig

Comments

This is a very interesting tip. Thanks.

Been making lots of mortise and tenon joints lately. I like this tip A LOT. Simple and I bet, effective. Can't wait to try it out on my next project. f

Very cool tip, and looks to be a lot easier than doing a draw bore joint for extra strength.

I plan to try this method next time I make M & T joints. Is there any reason you couldn't dispense with the hammer and anvil altogether and just use the vise to compress the tenon ?

Hydrating the wood with glue will make it swell, but when the moisture dissipates the wood will shrink to it's crushed size. Therefore, if you crush the wood too much you will get a weak joint.

L also want to try this. I like this on paper, real life is another thing

"Hydrating the wood with glue will make it swell, but when the moisture dissipates the wood will shrink to it's crushed size. Therefore, if you crush the wood too much you will get a weak joint."

I don't think so. I have used water many times to take accidental dents out of unfinished wood. The dent swells back to pre-dent size and does not shrink back when dry.

Folks... the fibers do NOT "shrink to its crushed size". Wood fibers are sort of like tiny straws. Once expanded, they will dry expanded, however they will be LESS resistant to crushing next time around. That makes zero difference, because along with the moisture, some of the solids from the glue will wind up in the "straws". Maybe not 100%, but enough that wiggling the joint won't re-crush them. This technique creates a VERY strong joint that resists getting loose down the road. Take the advice of "clamp the sides of the joint" seriously... I did this with some simple pine face frames in 3/4" stock -

+1/4" tenon and -1/4" either side of the mortise.. and the swelling of the tenon SPLIT the mortise with the grain and ruined the piece. And for the record, no amount of trying to squeeze the thing back down to original thickness with a handscrew worked - blowing the theory that the tenon is going to shrink back to original size.

PS... I think the Japanese hammer and anvil is a waste of time... just make two passes on your tenon with your vice. Squeeze it once near the shoulders per this article... then just slide it slightly out of the vice and squeeze additional times until you get to the end of the tenon. Takes seconds. Or, I guess you could start at the end and work towards the shoulders- it really shouldn't matter.

Log in or create an account to post a comment.

Sign up Log in