How to cut large stock with a miter saw

Crosscutting an 8/4 maple board can be an exercise in frustration, but with proper technique it can be done consistently and accurately

The following was a question sent in to Rollie. If you have a question, send it to: [email protected]

Hello Rollie,

I’m a bit backed up on my reading and just came across your statement about radial arm saws in the Editor’s comments, June edition, FWW #261. Having worked with a monster radial arm saw in my high school shop, I completely agree with you. In fact, I’ve always wanted a radial arm saw; I just don’t have the space.

That said, I do have the Bosch 12-in. Glide Miter saw. My question is about the proper technique when cutting. Should I plunge and then pull, like a radial arm saw, or pull, plunge, and push? In other words, cut back to front or front to back? My saw is set up properly with a negative hook blade.

Also, do you have any recommendations on setup? No matter how meticulously I “tweak” the adjustments, it just doesn’t make a front-to-back/top-to-both-surfaces square cut. As a result, I use it mostly for rough milling or carpentry work where the cut isn’t critical and leave the fine cuts to my Incra Miter Slide 5000 and tablesaw.

I look forward to hearing from you,

-Bruce

Hello Bruce,

When it comes to accurately and easily crosscutting thick hardwood lumber, a radial arm saw is tough to beat. A heavy cast-iron frame, easy-rolling precise motor-carriage, and powerful direct-drive motor combine to create the saw we all want when crosscutting.

Unfortunately many of us are relegated to using a power miter saw for crosscutting heavy timbers. Although they are excellent saws for cutting face-frame stock and millwork, they can struggle with the big stuff. The light saw chassis demanded for easy portability, plus the small motors that can run on 110-volt power and are light enough to be easily portable, add up to a saw that isn’t really the brute needed for the big stuff. Crosscutting an 8/4 maple board can be an exercise in frustration. But there’s a better way.

I’ve developed a method for cutting heavy stock that with a little practice will provide clean, accurate cuts in timbers as thick as the saw’s capacity can handle.

To start, it’s essential to have the correct blade and, as you stated, that is a negative-hook-angle blade. A negative-hook-angle blade has teeth that are angled back from from the centerline of the blade, creating a cutting action that is more of a scraping action than the aggressive cutting action of a positive hook-angle blade. These two blades show the obvious difference: The top is negative hook, bottom is positive hook.

The negative hook-angle helps limit the blade’s ability to self-feed, creating a much safer cut. Too many times I’ve seen positive-hook-angle blades on chopsaws and radial arm saws and typically the owners of the saws complain about the saw being “grabby” and difficult to control.

When cutting heavy timbers, I start by clamping the wood tight to the table. It’s essential that the wood can’t move during the several passes it takes to cut through the timber.

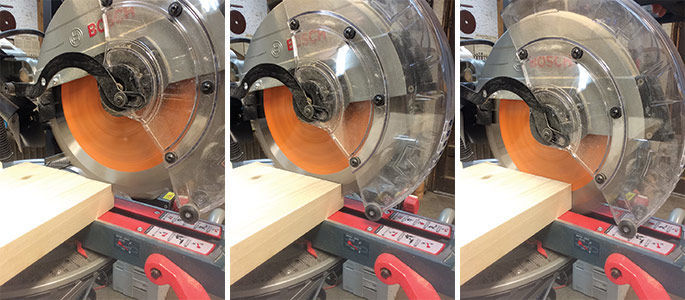

I extend the arm (or slide the motor past the wood) then lower the blade partway and push the spinning blade through the timber. It won’t cut all the way across the face. A bit will remain uncut at the back, but you’ll cut through that as you lower the blade through the wood. The second cut is the same as the first, just slightly deeper, and the subsequent cuts continue the process. Typically I will make three or four passes through thick hardwood; the trick is to keep the motor speed at full bore. If the motor slows, it frequently creates vibration in the blade, resulting in a rough cut. These saws are designed to cut best at full speed. However, moving the saw too slowly can create too much heat and scorch the wood. Practice a bit before committing to cutting important timber. The result is a smooth, square end cut that doesn’t try to fry the motor, scorch the timber, or drive the blade into a vibrating frenzy. Of course if you have a simple swing-arm chopsaw this method won’t work, and you’re sort of on your own when it comes to getting an accurate cut, but taking little bites and letting the saw keep its speed up will help tremendously.

If you have a hard time manually controlling the depth of cut, you could set the depth-stop on the saw to limit the depth of each pass. But that’s kind of tedious and with a little practice controlling the depth manually is no problem.

My recommendation on achieving accuracy with a power miter saw amounts to “you get what you pay for.” Good power miter saws aren’t cheap but with a good-quality saw, a top-quality blade, accurate setup (read the owner’s manual … really), and a little patience when cutting, the results will satisfy most crosscut or millwork applications. If absolute precision is needed, I find that a sled on the tablesaw is still the best.

Fine Woodworking Recommended Products

Rockler Dust Right 650 CFM

Makita LS1219L Miter Saw

Starrett 12-in. combination square

Comments

No mention of a thin kerf blade? It makes all the difference in the world to 120V saws.

I am constantly amazed at the bad rap radial arm saws get as compared to table saws or miter saws. Here is a good example where a radial arm saw would shine...

Ely

The first thing I had to do to get a good set-up on my Bosch 12" slide box was throw the factory blade away. Hard to get a good square set-up and smooth cut with a blade that wobbles.

Love a radial arm saw. Used to do everything only on that machine. I'm stunned when I tell carpenters in Oz(my new country) that you can do this and that and much, much more on a radial - arm or table saw, they look at me in total disbelief, and immediately start Googling to see if I'm telling the truth.We were a breed almost before routers became the rage to do everything on and with.I still do most things on my table saw, it's instinctive . my table's flatter, my fence is more stable(and accurate) and my sliding table is just a dream.But that's just me. PS . I do own probably nine or more routers.

Log in or create an account to post a comment.

Sign up Log in