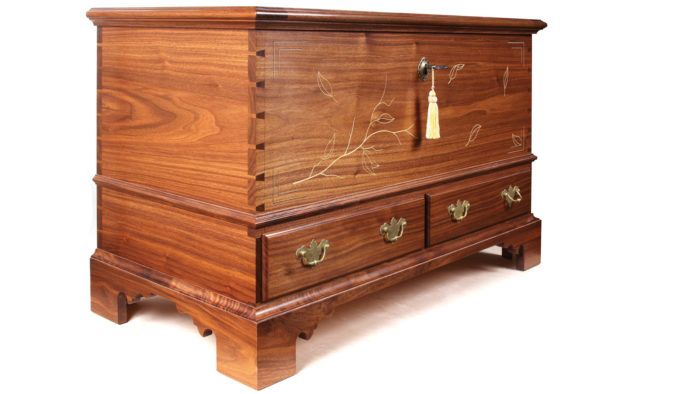

Synopsis: Take traditional stringing inlay to a new level with Steve Latta’s technique, which allows for lines that taper in thickness and transition smoothly between different widths. This gives his pattern a more organic, contemporary feel. Here he shows how he worked out a design for a chest, starting on paper and then making an MDF pattern, cutting the grooves with a Dremel tool and smoothing the intersections and transitions between different widths.

Over the past several years, I’ve tried to push the limits of traditional stringing patterns, which are basically a combination of straight lines and regular arcs, into freer, more organic forms that have a lot more life. Using patterns to guide a Dremel tool with end-mill bits gave me a new design vocabulary free of geometric constraints. To add realism and vitality to these designs, I taper the lines, routing adjacent sections with bits of different diameters, then smoothing the transitions between them by hand. The inlay on this chest that I made for my wife, Elizabeth, illustrates this effect.

After working out the design full size on paper, make several copies. Spray-mount one copy to a piece of 1⁄2-in.-thick MDF and cut out the pattern using a scrollsaw with a no. 9 blade. Mark the end points of the lines in the design, but continue cutting to the edge of the pattern or merge into another part of the design. Reassemble the pattern pieces and make registration marks between them to show how they align.

I place registration pins along the bottom segment of the pattern so that I can remove and remount it accurately. Since this bottom section is the foundation for the design, properly positioning it aligns the entire form.

When you cut a groove, the shank of the bit rides directly against the MDF pattern. As long as you keep the tool moving, the pattern will hold up. Leave it in one place too long, however, and you’ll burn a notch into the material. To avoid creating a noticeable starting point, tilt the Dremel before turning it on, and pivot the bit into the work along the same line you’ll be cutting. Entering the work from the side results in a small entry slot that can easily be avoided. To finish a groove, cut the power to the Dremel but keep the tool moving, sliding back into an area previously cut as the rotation winds down.

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Bahco 6-Inch Card Scraper

Whiteside 9500 Solid Brass Router Inlay Router Bit Set

Log in or create an account to post a comment.

Sign up Log in