Hone Gouges with a Dowel, Sandpaper, and a Drill

This simple but effective shopmade tool takes the place of slip stones and other expensive gear for honing carving gouges.

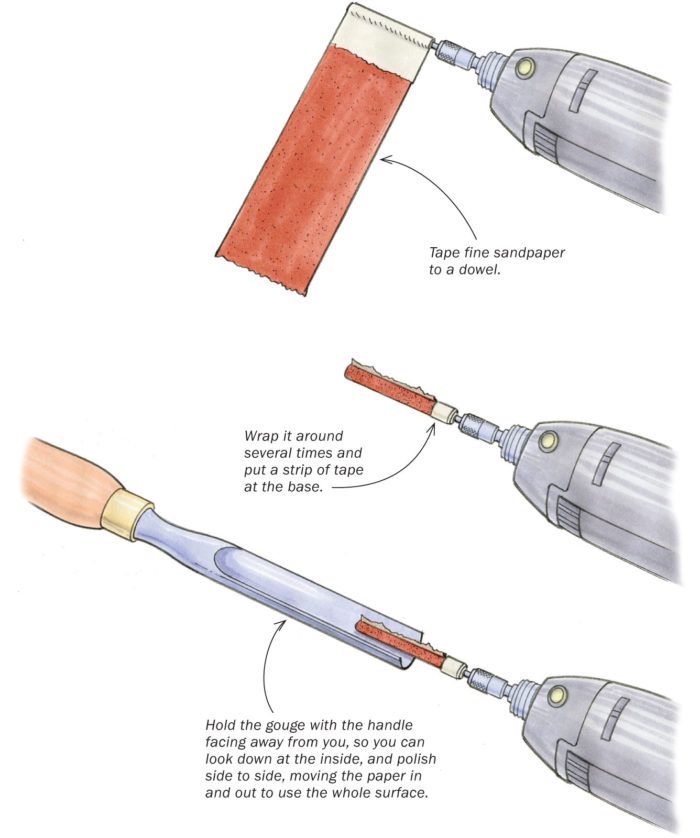

Here is a simple but effective shopmade tool for honing carving gouges, taking the place of slip stones and other expensive gear. It’s a dowel with fine sandpaper wrapped around it, chucked in a rotary tool. For smaller gouges I use a 1⁄8-in. dowel about 2-1⁄4 in. long in a Dremel tool, and for larger gouges, I chuck a 1⁄4-in. rod in a die grinder. A drill set on its highest speed would also work. The spinning roll does a beautiful job on the inside edge of gouges, both out-cannel (bevel on the outside) and in-cannel (bevel on the inside). This leaves only the outside edge to hone on normal stones, finishing up with a leather strop.

The trick lies in how you wrap the sandpaper around the dowel. Cut a strip of wet-or-dry paper wide enough to fit the exposed rod and long enough to make several wraps around it. Tape the sandpaper to the rod as shown and wind it on tightly. Then use a thin piece of tape to bind the paper at the base. That’s it. If the gouge has particularly nasty scratches, I start with 400-grit paper, but more commonly I start with 800 grit and work my way up to 2,500. I keep a cup of water handy and dip the paper to lubricate the process. The spinning sandpaper roll will have a tendency to catch on one side of the gouge. So I stop just short of that side. When the paper dulls, it’s easy to renew: Just make a short tear along the tape at the base and then tear off the used section to expose the fresh paper. Now I no longer avoid tuning up new or old gouges.

—Kirk Hopkins, Brashear, Texas

Illustrated by Dan Thornton

Fine Woodworking Recommended Products

Norton Water Stones

Honing Compound

Rockler Silicone Sharpening Stone Tray

Comments

Would you suggest this for concave turning tools as well?

I do.

Log in or create an account to post a comment.

Sign up Log in