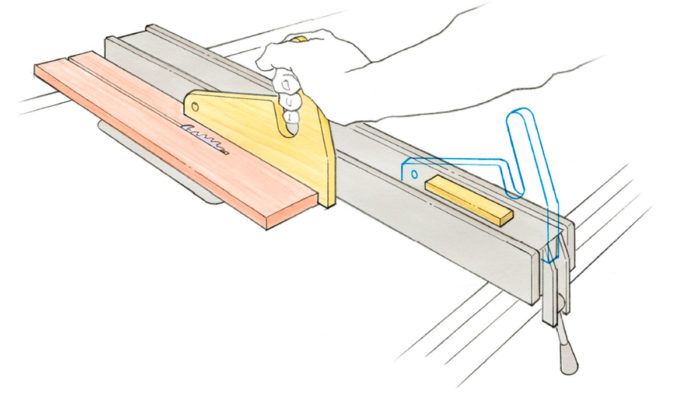

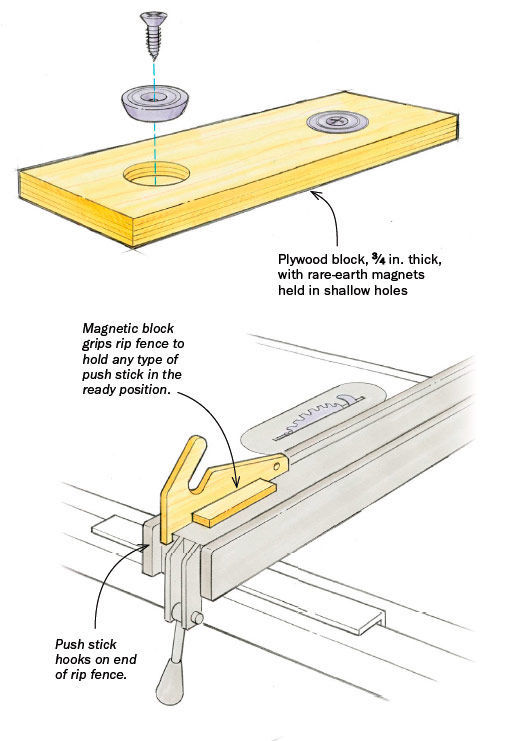

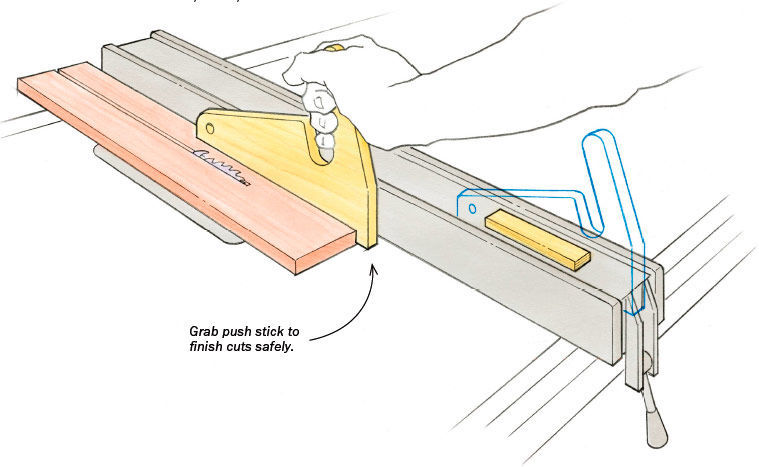

Thirty years of teaching woodworking has convinced me that woodworkers will use a push stick consistently—if it’s convenient. If not, they’ll often go without, finishing cuts by squeezing a few fingers past the blade. To make the tablesaw safer I designed a simple holder that keeps your favorite push stick upright on the rip fence. With the push stick nearby and poised for action, you hold a workpiece securely in both hands as you start a cut, and scoop up the stick as your hand passes by, finishing the cut safely. The small magnetic block lets you pull the push stick off the rip fence at any angle. If the block moves in the process, you can just push it back against the stick when you return it to the ready position.

The holder is a small wood block that attaches to the rip fence with rare-earth magnets, and squeezes almost any type of push stick against the edge of the fence face to keep it vertical. You can epoxy rare-earth magnets into the bottom of the holding block, but I used the type held with a screw (Lee Valley no. 99K39.04).

—Barry Thalheimer, Prince Albert , Sask., Canada

Illustrations by Dan Thornton

From Fine Woodworking issue #271

Fine Woodworking Recommended Products

Fein Turbo II HEPA Wet/Dry Dust Extractor

Veritas Wheel Marking Gauge

Stanley Powerlock 16-ft. tape measure

Comments

I'll admit that I'm not an experienced woodworker, but the problem that I see with all of them is that they are unstable. This one is no different. Pushsticks actually scare me. What if it tipped over? What if the hook lifted above the workpiece allowing the stick to move forward and also likely tip? Goodbye hand.

I think that the best pushsticks are those that straddle the rip fence and ride over its length.

Log in or create an account to post a comment.

Sign up Log in