How to Make an Adjustable-Height Shop Stool

The tail jaw of a 3/4-in. pipe clamp makes a perfect seat-adjustment mechanism.

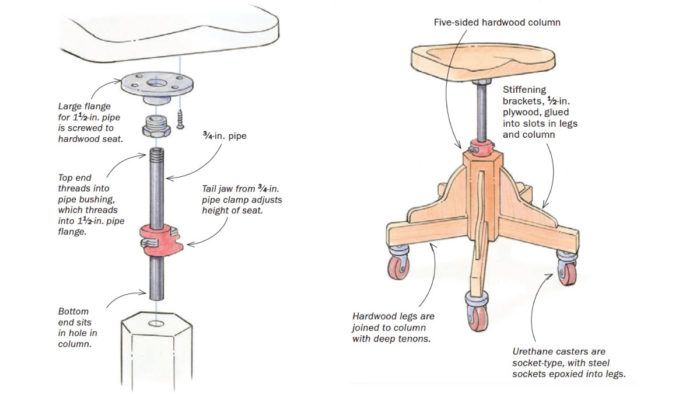

After breaking one of the legs on my shop stool, I decided to build an adjustable version. I made the base from a pentagonal hardwood column, attached five hardwood legs with deep tenons, and then, for additional strength, routed slots in the column and legs for plywood brackets. After adding casters to the legs, I went on an unsuccessful search for a seat adjustment mechanism. Then the perfect solution came to me: the tail jaw of a 3/4-in. pipe clamp.

The bottom end of the pipe goes into a hole in the column, with the clamp jaw resting on top. At the top end, I threaded on a pipe flange for attaching a hardwood seat. To make the seat as strong as possible, I used the largest pipe flange I could find at the home center, which has a 4-1/2-in. overall diameter and fits onto 1-1/2-in. pipe. To make that work I screwed a pipe bushing onto the end of the 3/4-in. pipe to take it to 1-1/2 in. dia. Then I attached the flange and seat, and started using my new adjustable stool right away.

Fine Woodworking Recommended Products

Estwing Dead-Blow Mallet

Sawstop Miter Gauge

Tite-Mark Marking Gauge

Comments

Great idea. Here is a question. Supposed I wanted to use the set up you show here to attach a large metal sphere to a piece of wood. How do I allow for the expansion of the wood with the changes in seasonal humidity?

Thanks

I know it's years later, but you use slightly undersize screws with washers between the screw heads and the pipe flange, so the screws can move in the flange holes with the wood.

How do you make a pentagonal column though?

Log in or create an account to post a comment.

Sign up Log in