STL181: Will a Jobsite Saw Cut It?

Anissa, John, and Ben discuss small shop solutions, table stretchers, shop lighting, and their recent smooth movesCheck out our newest video workshop, Enfield Cupboard with Hand Tools featuring Chris Gochnour and be sure to help us make our video workshops even better by filling out this quick survey.

Question 1:

From Dean:

I have an enjoyable dilemma. I am building a garage with adjacent shop space at our north home. The shop is 200 sq-ft, one third the size of my St. Paul shop, and thus creates a challenge adapting to a small space. I have been devouring all the FWW articles on small shops and believe I can make this space workable but I will have to make some concessions, mainly my tablesaw, jointer, and planer. Will I be satisfied and served by a portable, contractor-style table saw and a combination jointer-planer?

Question 2:

From Tanc:

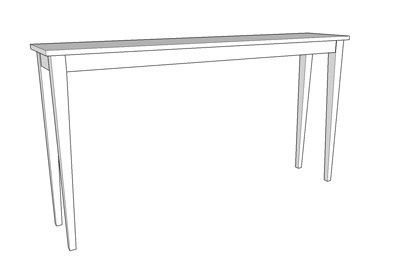

Is there a guideline for when stretchers are needed to strengthen a piece? I am looking to build an entryway table from oak that is 32-in. high, 60-in. long, 12-in. deep, with a 2 ½-in. apron and 2-in. legs that taper down to 1-in. I prefer simple designs, and would rather not have stretchers.

- Floating-Top Table by Michael Pekovich #263-Sep/Oct 2017 Issue – http://bit.ly/2zKD2pw

- Engineer Shelves With The Sagulator by Bill Kovalick #190–Mar/April 2007 Issue – http://bit.ly/2SUSKpk

- Brass Stretcher Brightens a Bench by Michael Robbins #267–Mar/Apr 2018 Issue http://bit.ly/2SUOztJ

- Given a common inspiration, three furniture makers create a diversity of designs by Mark Schofield #184–May/June 2006 Issue – http://bit.ly/2SR2fWA

Ben’s mockup of Tanc’s table with the given dimensions:

Benside Table:

Segment: Smooth Moves

John: Not cleaning the lint off of a new floor finish applicator

Anissa: Touching a friends piece of furniture while the finish was still wet

Ben: Trusting a tool that should never have been trusted

Question 3:

When I set up my workshop, I positioned the bench facing a south-facing window and installed fluorescents directly above the bench at about eight feet above the floor. If I have a board on edge, any markings on the side facing my body are difficult to see because that area is in shadow. I want to avoid using task lights wherever possible, as they just get in the way. I’m thinking that more overhead lighting is the answer. Do you have any thoughts about where this should be positioned to minimize shadow areas when working at the bench?

Question 4:

From David:

I am baffled that some ash stock I milled a couple months ago is now nearly impossible to plane. I cut and milled the ash for a small box a while ago. It was wonderful to work with and easy to plane. I put the pieces aside to enjoy the far too short Minnesota summer. I kept it in the same place all my wood stock lives; my basement workshop. I was looking forward to getting back to work on the box. I decided to plane all the pieces again, assuming it wouldn’t be flat and square as it was months ago. I was dumbfounded that it was nearly impossible to plane. I used the exact same plane I used originally.

I ended up resharpening the blade twice and adjusted it to take the finest possible shaving. Still it would stick and chatter across the board and leave tear out in the middle of smooth grain. To make sure I wasn’t hallucinating, I tried planing some oak and some twisty walnut. It performed beautifully. It was as though it had developed a skin of steel in the time since I first milled it.

Any ideas about what/why this happened?

Recommendations:

Ben – PBS’s Craft in America episode–Visionaries

Anissa – American violin maker–James Reynold Carlisle

Every two weeks, a team of Fine Woodworking staffers answers questions from readers on Shop Talk Live, Fine Woodworking‘s biweekly podcast. Send your woodworking questions to [email protected] for consideration in the regular broadcast! Our continued existence relies upon listener support. So if you enjoy the show, be sure to leave us a five-star rating and maybe even a nice comment on our iTunes page.

Comments

Regarding Dean’s question: I know quite a few people who are happy with jointer/planer combos but if possible try to steer clear of contractor table saws. As a recent convert to a cabinet saw, I still can’t believe how much quieter, more stable, precise, and just more pleasurable it is to use. I think it’s well-worth sacrificing some floor space to make room for one in your shop.

I agree with Kevin, I am using the Makita Asian version with a sliding table now and some things it is a bear to use and would kill for the space of a nice cabinet saw. By the way I watch many of your Shop Talk Live and they are quite entertaining as well as informative. From the Philippines. ( ex-pat )

Lol, Benside Table.

Hey Guys,

Speaking as a mechanical engineer, the commenter on STL 181 was right. Deflection of a beam under a fixed load relates to the length of the beam cubed. Twice as long means 8 times as much flex under the same load. Fortunately, twice the load means only twice the flex (more or less).

That is assuming it does not start to twist, of course. Mike was correct about that. I'd disagree with the commenter who suggested making it more square though. You want to increase something called the 2nd moment of area. In general, like an I beam, you want to increase the height of the apron, because that increases the 2nd moment by a factor of H cubed. Twice the height means 8 times the 2nd moment and 1/8 the flex. Increasing the thickness increases things linearly - twice the width means twice the 2nd moment and half the flex, provided it does not twist. (Twist may have been what that commenter was thinking about.)

So, if the bench is twice as long, and will carry twice the load, we'd really want 16X the 2nd moment to resist that deflection (simplifying things a bit). That'd be achievable with twice the apron height and twice it's thickness, or by 2.52 times the height and the same thickness.

Of course aesthetics may limit the desired apron height....and, without actually sitting on it, it is hard to judge how much flex will feel too flimsy.

These equations must be behind the Sagulator, and so (assuming you don't just put more, taller books on the next shelf down, Annisa) you can use that to play with these sorts of questions as well.

Secondly, I use my headlight all the time. Great for looking inside a deep mortise (e.g. a tusk tenon).

--

-Stephan

p.s. Ben, it's a plastic pair of calipers. Whoever bought it should have

a) opened the package

b) removed the calipers

c) deposited calipers and package straight into the appropriate trash and recycling bins

d) gone and bought a decent pair of calipers (read - metal)

Stephan

I love my plastic calipers. Plenty accurate and it's one tool I've never needed to upgrade. I keep several of them laying around the shop. But I understand a broken piece would be bad if not noticed...

Thanks for taking my question about the mysterious hardening of some milled ash boards. This may make the issue even more difficult to resolve... between the time I first milled them and I started again, I kept them all together in a plastic bag, which I left open so moisture wouldn’t be trapped inside. So it would seem that they were protected from the shop atmosphere and that whatever did happen would happen to them all on all sides. I did that because I learned the hard way that if you don’t build the piece shortly after milling, you cannot count the board being flat or straight. I’m still baffled by the change in the surface of the wood. Incidentally, once I removed the outer 1/32 “, I could again plane them easily.

Thank you for reliability turning out the podcasts. I’ve listened to every one of them since I started listening over three years ago. They are well organized and professionally produced. It’s great to hear from people who do woodworking every day; their techniques, their tips and their screw ups.

Years ago, I had build a similar table to your entryway table from oak with dimensions were 34-in. high, 48-in. long, 10-in. deep, with a 2 ½-in. apron. I had 1.5-in square legs and also no stretchers. It was used to support a sewing machine and a serging machine - lot's of vibration. It has lasted for many (+15) years. Eventually it went of to college with my daughter and still holds together nicely for her. I am convinced that it will be fine with the dimensions given as long as one uses oak.

On question 3, lighting over a bench - go ahead and put strip lighting over the bench, but perpendicular to the bench. Perhaps 2 lights, depending on the length of the bench.

Ben - This episode was painfully slow for the first 15 minutes. I kept forgetting that John Tetrault was there. He needs a double espresso 45 minutes before you start recording. You need to do what the talk-shows do, have a warm-up before the show starts. Find an angle that gets people's creative juices flowing. Once you get Anissa a little angry she is much more interesting (there used to be a certain someone on the show who was rather good at provoking everyone else - It makes for good pod). The rest of the time, once the rust was off the wheels, was a good show. Don't be afraid to edit out the crickets.

The Chris Gochnour Enfield Cabinet video is fantastic. It sets the standard for hand-tool furniture demonstrations as far as I am concerned. Keep up the great video work.

One thing I need to know from Jeff: Lupo's Char Pit, Spiedie and Rib Pit, or Sharkey's? Now that will start an argument in Broome County.

Another question for John - has he purchased all the 20/4 hickory in the country? Where can I get some to build his hybrid Roubo bench? You need almost 20 ft of it. And yes, I am willing to drive to his barn to get some.

"Kinda like a headlamp on a drill press."

Amazing.

Log in or create an account to post a comment.

Sign up Log in