How to Add Strength and Style to Any Slab

Inlays transform a flawed slab into a sturdy work of art.

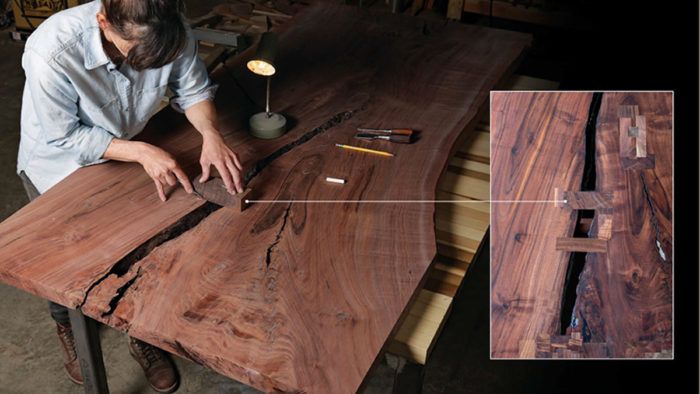

Synopsis: Large slabs are stunning when used for counters, tables, beds, and benches. But they are rarely perfect. Audi Culver and Ivy Siosi turn flaws into design assets through the use of inlays. Often overlapping and always artistic, these inlays are used to mend cracks, increase thickness, add strength, and make the most of any slab’s inherent beauty.

One of the many things we do at Siosi Design + Build is work with large slabs, which we use for tables, counters, beds, and benches. Although we look for slabs that have as little checking as possible and overall good grain flow, it is rare to find one that is structurally perfect. Often imperfections lie in crucial areas that we can’t or don’t want to cut off.

We solve this problem using a technique we first tried on a large walnut slab that had a soft spot right beside a flame crotch. We were unwilling to cut out the bad and lose the good. Our designs lean toward modern and minimalist, so rather than using a more traditional butterfly key to shore up the structural and visual imperfections, we developed a method that reflects our overall vision without sacrificing strength. This technique is both aesthetic and practical, reinforcing flawed areas and adding a sculptural quality.

Take inspiration from the flaw

Using the inherent flaws in each slab as inspiration, we add inlays to mend knots, increase thickness, and reinforce cracks. We consider which flaws to embrace, and which ones are unsightly or need to be reinforced for the longevity of the piece.

The goal is to strike a balance between the raw, natural beauty of the wood itself and a refined, sculptural finished piece.

We consider which imperfections add to the aesthetic of the overall piece, and which knots and cracks detract—some elements are inlaid over, others are embraced. Cracks that are left open are sanded, debris is removed, and any rough spots where dust and crumbs may nestle are smoothed.

Video: Siosi Designs–Our Lives In Frame

Audi Culver and Ivy Siosi, describe themselves

as partners in life, collaborators in design,

and women who make + fabricate

There is potential for cracks to continue to expand; those areas are mended with inlays to prevent further movement. When there is a hole or crack that we decide to keep, but there’s potential for it to be a crumb catcher, we fill small knots and holes with epoxy. We use this technique sparingly, since wood movement and epoxy can sometimes be an issue down the road. The goal is to retain the look of the flaw while reducing some of the inevitable maintenance required if we retain the flaw (such as dusting with canned air). By nature, each slab is unique, and each client is unique. We try to match and honor the two.

Start by selecting and milling inlay

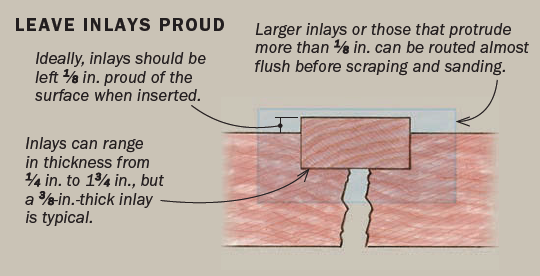

The key to this process is patience, a few sharp tools, and a vision. We address the biggest issues first. We start with large, structural inlays and add smaller pieces as we go. The size and depth depends on the specific project, but we have used inlays as large as 12 in. by 16 in. by 1-3⁄4 in. deep and as small as 1⁄2 in. square by 1⁄4 in. deep. We cut small inlays with a bandsaw, while we tackle larger pieces primarily on a tablesaw with a crosscut sled.

To view the entire article, please click the View PDF button below.

From Fine Woodworking #274

More on Finewoodworking.com:

-

Level Big Slabs in No Time Flat By Nick Offerman #222–Nov/Dec 2011 Issue

-

Success With Large Slabs by D. Douglas Mooberry #206–July/Aug 2009 Issue

- Discover the Beauty of Big Slabs by Nick Offerman, Robert Ortiz, John C. Sterling #252–Jan/Feb 2016 Issue

Fine Woodworking Recommended Products

Whiteside 9500 Solid Brass Router Inlay Router Bit Set

Bahco 6-Inch Card Scraper

Log in or create an account to post a comment.

Sign up Log in