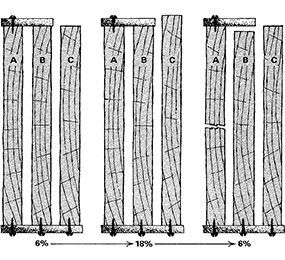

Wood technology has aways been a favorite topic of mine, specifically as wood movement applies to solid-wood furniture construction. My first run-in with this problem came in high school, when I made a plant table, about 2-ft. square, overbuilt with screws and glue. My mom placed it over a hot air vent and the top cracked within a week. The shop teacher smiled and said, ”You didn’t let the wood move.” Huh?

In 1976 I was one of the first subscribers to Fine Woodworking. Bruce Hoadley, a wood technologist and carver who was a contributing editor to the magazine from the first issue, began to shed light on the subject of water and wood, expansion and contraction. Several of his articles opened my eyes. In 1979, I’d learned enough to be dangerous, and finally decided to dig a little deeper. I took a Wood Technology course at the University of Southern Maine. When Bruce Hoadley’s book Understanding Wood came out in 1980, I read it cover to cover.

When I opened my own shop in 1986, I completely re-thought and re-designed all my case pieces to allow for wood movement, no matter what part of the country my work ended up in. This is part of the building and design process that I take extremely seriously. Once a piece is paid for, I never want to see it again. So far, so good; but then, I knock on wood every day. FWW is such a great place to pick up those small but essential hints that help you become a better woodworker.

Chris Becksvoort

Contributing Editor, Fine Woodworking

|

WoodA look at this fundamental material by R. Bruce Hoadley |

|

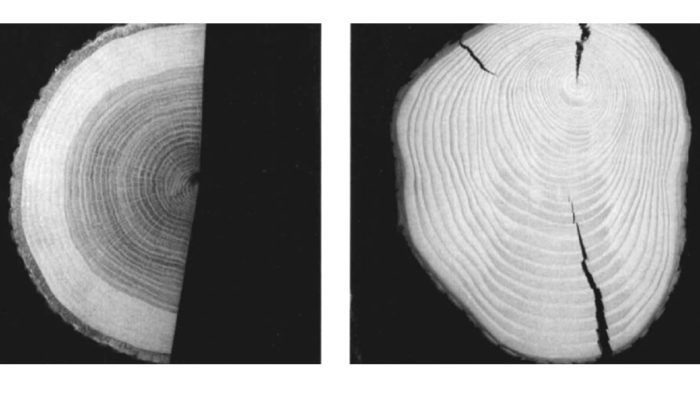

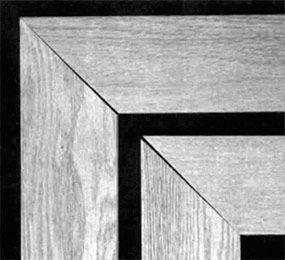

Water and WoodThe problems of a difficult pair by R. Bruce Hoadley |

|

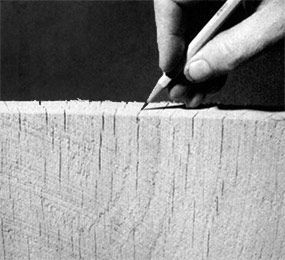

Drying WoodThe fundamental considerations by R. Bruce Hoadley |

|

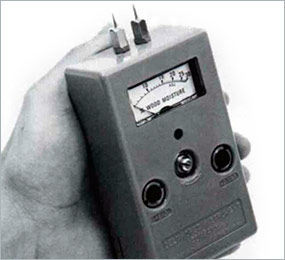

Measuring MoisturePortable meters prevent guesswork and grief by R. Bruce Hoadley |

|

Wood Has to Breathe Doesn’t it?Tackling some big myths by R. Bruce Hoadley |

Log in or create an account to post a comment.

Sign up Log in