Reading Wood Grain–Don’t Fight the Fibers

Better ways to read grain and make the most of your lumber

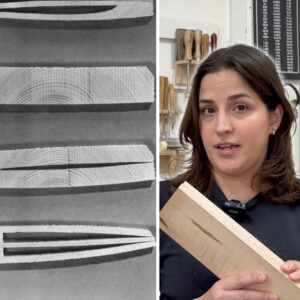

Synopsis: Jason Roberts knows lumber (he sells it) and woodworking (he’s been making furniture for years). As a result, he knows reliable ways to read the grain and avoid tearout on all types of wood. As he explains, the cells that grow vertically in the tree, known as fiber, are the key to the whole puzzle. Roberts takes different approaches with different woods, combining clues he gathers from reading rings, rays, vessels, and fiber cells to map out a strategy for smoothing almost any wood without tearout.

Like most woodworkers, I’ve learned about grain direction the hard way. I still remember the sound a beautiful piece of spiderwebbed Brazilian rosewood made when I sent it through a planer with dull knives, nor will I forget seeing it emerge with terrible tearout. I was making a jewelry box for my girlfriend, and I nearly wasted that pricey piece of wood. In the end I had to make the sides much thinner than I wanted.

I’ve now been cutting, drying, and selling high-end lumber for furniture and instruments for more than a decade, and I’ve been making furniture for much longer than that. Along the way I’ve learned a number of reliable ways to read grain and avoid tearout, whether I’m surfacing the wood using power tools or by hand. I’ll help you make the most of your materials and avoid mistakes reading grain.

Video: Understanding grain – It’s essential to understand

tearout in order to prevent it, in this video Michael Pekovich

demonstrates his methods for reading the grain while hand planing.

In this article, I’ll refer collectively to the various longitudinal cells in wood—the ones that grow vertically in the tree—as fiber. Learn how to read the fiber and you’ll head off tearout before it happens. Even when you can’t prevent it completely, you’ll know how to minimize it, making it faster and easier to produce the flat, flawless surfaces that characterize high-end work.

How tearout happens

Trees taper as they grow, and tree trunks aren’t always straight. So when boards are cut out of a log, the fibers often run at an angle to the surface. Wood always wants to split along the fibers. When you plane in the wrong direction, tiny splits dive forward and down ahead of the blade and little chunks of wood lift up and break off, leaving the jagged divots we call tearout.

Joint, plane, or handplane the board in the right direction, and the fibers will lie down nicely and cut cleanly. Whether the board is riftsawn, quartersawn, or flatsawn, reading the fiber direction and approaching it correctly is the key.

Of course, wood is an organic material, and not all boards can be planed cleanly in one direction. Trees crook and twist, branches and knots intervene, and grain sometimes changes direction along the length of a board. Some tearout is inevitable.

In fact, some boards are hard to plane cleanly in any direction. Figured woods are especially tricky, with curly figure, burls, and bird’s-eyes. Exotic woods with interlocking grain are also tough. And in some woods the rays are prone to tearout no matter which direction you plane or cut. There are boards with straight grain, mostly parallel to the surface, that won’t tear out no matter what you do. Air-dried wood is also forgiving, even when it’s figured.

From Fine Woodworking #275

To view the entire article, please click the View PDF button below.

Fine Woodworking Recommended Products

DeWalt 735X Planer

AnchorSeal Log and Lumber End-Grain Sealer

Grout float

Log in or create an account to post a comment.

Sign up Log in