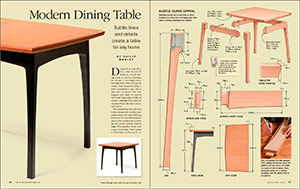

Modern Dining Table

Phillip Morley creates a table with subtle lines and details for any home.

Synopsis: Tapered, splayed legs that transition into curved aprons, a clear-finished mahogany top with a contemporary profile, and an ebonized base—these are the stylish elements that make up Philip Morley’s dining table. For all its sophistication, this table is not difficult to build. Construction includes mortise-and-tenon joinery and the use of templates to dial in the curved parts.

Designed to seat four, this table would fit nicely in a small dining room or kitchen. Because its design is uncomplicated, favoring clean lines and gentle curves over ornamentation, it will complement just about any style of decor. The mahogany top, with its curved sides and crisp edge profile, is clearly contemporary, and the ebonized base also has a modern appeal.

The splayed legs are attached to the aprons with mortise-and-tenon joints, but their defining feature is the way their tapered sides curve as they rise to meet the arc on the aprons’ bottom edge. The junction looks like a gun-stock joint, but I make it differently, preferring to cut the tight curve into just the leg rather than splitting it between the leg and apron. I’ll show you how I do it, and how I create the tapered chamfer on the leg’s outside edge.

The splayed legs are attached to the aprons with mortise-and-tenon joints, but their defining feature is the way their tapered sides curve as they rise to meet the arc on the aprons’ bottom edge. The junction looks like a gun-stock joint, but I make it differently, preferring to cut the tight curve into just the leg rather than splitting it between the leg and apron. I’ll show you how I do it, and how I create the tapered chamfer on the leg’s outside edge.

I’ll demonstrate how I shape the tabletop’s curved sides and edge profile with three off-the-shelf router bits. The techniques are not difficult, and when you’re done with the table you’ll have a graceful and welcoming place for meals with friends and family.

Phillip Morley’s elegant table legs are a

lot more approachable than you might think.

In this video, Phillip demonstrates his methods

for making a run of these curved wonders.

Curved joint is easier than it looks

Part of this table’s presence comes from its gently angled legs. The transition from leg to apron begins a curve that carries along the apron and back to the opposite leg. On the leg’s outside corner, there is a chamfer that narrows as it travels down the leg. The legs and aprons begin as rectilinear blanks, and I cut the mortise-and-tenon joinery in them while they are still square. Keep in mind that the legs slope outward. After the joinery has been cut, I shape the bottom edge of the aprons with a template. Trace the curve on the apron, rough it out, and then rout flush to the template.

Download the plans for this table from the Digital Plans Library. Plus, browse 100+ other plans available for members only.

From Fine Woodworking #275

To view the entire article, please click the View PDF button below.

More on FineWoodworking.com:

- Designing for clients by Philip Morley

- The Struggle of Pricing Your Work by Philip Morley

- Easy Technique for Gluing Thin Panels by Philip Morley #264-Nov/Dec 2017 Issue

Comments

My wife loves how this table looks and asked me to make it. I have been making furniture for about 6 years now as a hobbyist and have used plans from this site for pretty much everything I have made. The article and the digital plans are surprisingly sparse in detail. If I was truly an inexperienced intermediate level woodworker I would have been mystified. The top and bottom of the legs are a cut at a compound angle- no mention of this at all anywhere in the article or plans. This has implications for the lower end of the mortises and therefore also for the tenons. The router bit (Magnate.net #5867) suggested for shaping the table top edge when used as depicted in the picture accompanying the article leaves a ridge at the bottom that would need to be planed away. Unfortunately that was not immediately apparent to me and my tabletop no longer as the elegant profile that Morley has on his table. My wife is going to be disappointed.

Without further detail with the plans and the article, I think this is is not an intermediate level project.

Thank you for your comment, I was just about to purchase until I read your comment. Although I'm sure I could figure it out, I would expect more from paid plans. Disappointing as we had planned for this to be our new breakfast table.

I have purchased the plans and have done a smaller mockup of the table using square blanks for legs so I could try my skills at doing angled tenons for the first time. That seemed to work our ok,but, I am confused about what to do with the bottom of the leg so that it sits flat on the ground after it is splayed at 4.5degrees off center? Does this work itself out once the curved template is cut or do Ineed to cut an angle while the legs are still square? Any advice on this would be appreciated.

The top and bottom of the legs are cut at compound angles. And top and bottom surfaces need to be parallel to each other i.e that is when bottom of the leg is flat on the ground the top of the leg is parallel to it.

I found it easiest to cut the legs to length on my compound miter saw - set the angle of the cut to 3.5 degrees AND the bevel of the cut to 3.5 degrees ( I used a digital angle gauge to set the bevel angle and did multiple test cuts after marking every cutline on the test pieces as well as on every one of the actual workpieces. Very easy to screw up the orientation of the parts, so check over and over again.

I too was a little disappointed in the lack of detail. The article could have spent a little more time on technique for getting the proper angle on the legs and aprons. Like others, I made multiple practice cuts on a table saw until I got the tilt and miter angles correct. Then cut the top and bottoms of the legs with the same setup to ensure they were parallel. Then I matched the apron angle to the leg angle to ensure the top of the leg and the top of the apron were in the same plane. I am cutting the legs after the aprons are fit. This should make it easier to blend the aprons with the legs

The picture caption in the article says a 2 inch finger nail bit is used but the body of the article says it is a Magnate #5867 which is a 1-1/2 inch bit. As noted in another's post this would leave a ridge on the bottom edge of the top. I cannot find a 2 inch bit anywhere. The larges bit I can find is #5869 which is 1-3/4 inch. I think the 5869 would work if it was lowered enough to not leave a ridge on the bottom edge. This would leave a slight round-over on the top edge but the chamfer bit should clean that up and leave a profile close to what the plans show.

Also, the article shows the radius on the leg is 1 inch but the plans show 1/2 inch. And the dimensions on the plans show the table top to be 1-1/4 inch wide. Neither of these is a big deal but better proofreading would be appreciated.

Update on Dec 23 post:

I bought the Magnate #5869 bit thinking I could make it work. Turns out there is an error in the Magnate catalog. #5869 is actually 2" and comes with spacers to make it even longer.

Thanks for posting this. I have been sitting here trying to figure out how to make the 5867 bit work if I bought it. Its too short. Now I know it’s the wrong bit. I need 5869.

Finished the table. I started it as a practice model and used construction grade lumber for the base ( hence painted black) and Ash for the top with general finish nutmeg and arm r seal satin varnish. All and all I’m pretty pleased with this table. If you do this project I suggest you read the comments in this forum since plans and article omit important information.

Another angle of table

Log in or create an account to post a comment.

Sign up Log in