Modeling in Place in SketchUp

Dave Richards demonstrates efficient SketchUp workflow, allowing the program to fill in the measurements based on work you've already doneIn the second part of the video in my previous blog post I showed how to use the geometry of a tenon on an apron to create the matching mortise in the leg. Part of what makes that an efficient thing to do comes with modeling parts in situ. This is a standard part of my work flow when modeling anything.

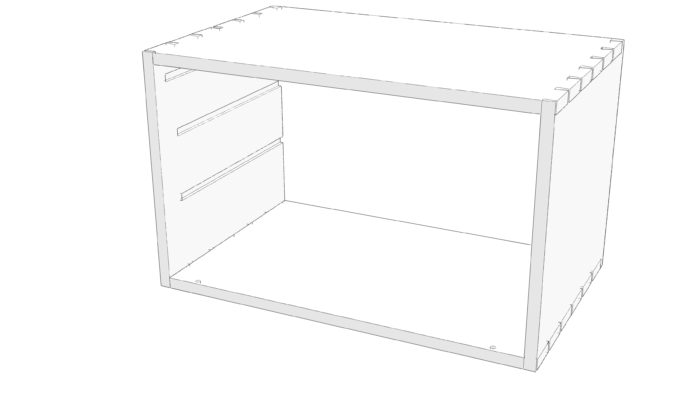

As an example, this is the case for Matt Wajda’s North Bennett Street School Toobox. When I created the model for it, I drew the left end of the case and made it a component. Then I copied it to make the right end of the case. Once those two parts were in place, the only dimension I needed to know for the bottom was the thickness. The width and length were determined from the outside limits of the sides.

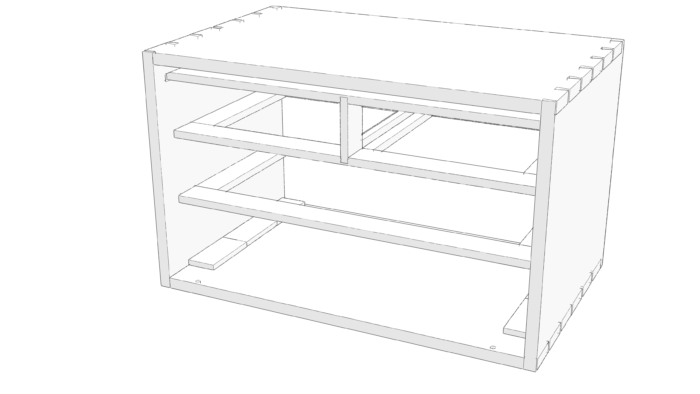

In the same way, I added the internal frames by working inside the case.

And then the drawer front dimensions were taken from the size of the opening created by the case parts and the dividers.

Working this way, you don’t need to know every single dimension in order to create the model. When you are ready to know those dimensions, you can have the program tell you.

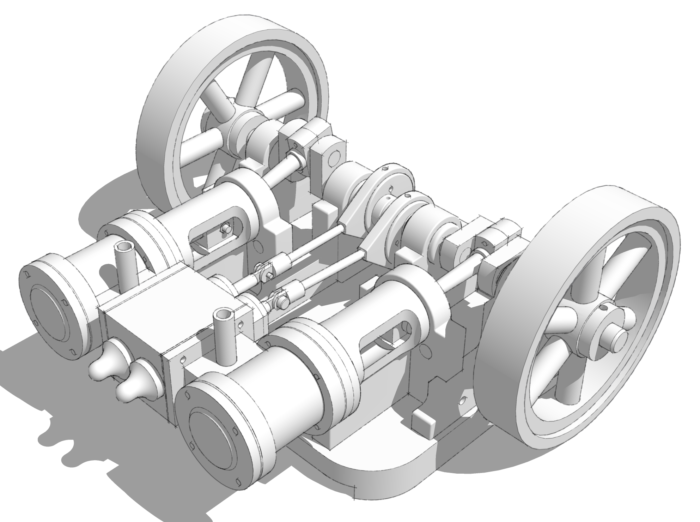

The other day I was working with one of my students. He was getting set to create a Sketchup model of a model steam engine which I had already modeled a day or so before. He asked how I was able to model it as quickly as I did and was surprised by my description of modeling in place. Once he gave it a try, though, he was hooked.

In the attached video, I’ll demonstrate how I do this sort of think by modeling the cylinder gasket and the cylinder top cover to fit the cylinder. Besides not need to enter a bunch of dimensions to create the parts, there’s no fiddling around to get the parts in the right place. I hope you’ll be able to glean some other helpful bits from this.

–Dave

Comments

Dave,

Your instruction is excellent and I always learn something new in "SketchUp" from every lesson. Often I skip back and look at aspects of your drawing steps in an attempt to drive it into my memory. Just want to say thank you for the blog and excellent camera work on each video segment you produce as each takes far more time than indidcated.

Thank you sir for the kind words. I'm happy to know there's something useful in my videos.

Log in or create an account to post a comment.

Sign up Log in