Waste not, want not: Practical uses for shop waste

Nancy Hiller shares a few ideas for what to do with all of the chips and dust created by a pro shop.

If you’re a professional woodworker, one thing’s for sure: you make a lot of chips. And dust. And scraps of wood that are too small to use (and perhaps too-small-to-use scraps of plywood, too). Most of us have methods for reusing or disposing of this stuff, but it never hurts to share ideas, especially when you discover one that’s beyond anything you would ever have thought of yourself.

Most woodworkers probably already know that jointer and planer chips can make good animal bedding. However, some species of wood (such as cherry and walnut, and probably some exotics too) are not compatible with some species of animal. Consult your veterinarian before subjecting your pets or livestock to potentially injurious material.

The same chips make nice, springy garden paths. Over the course of a few years, the chips will be worked deep into the soil, loosening it and making for excellent tilth.

The same chips make nice, springy garden paths. Over the course of a few years, the chips will be worked deep into the soil, loosening it and making for excellent tilth.

Planer and jointer chips also make a reasonably good mulch, the main caveat being that you’ll have to add nitrogen. You can do this with store-bought fertilizer. If you have a shop cat, he or she may have added some nitrogenous matter, which may also help keep deer, rabbits, and other sometimes-undesirable garden visitors at bay. (The jury’s out as to whether kiln-dried walnut chips will adversely affect the growth of other species, so it would be prudent to avoid using walnut unless you have input from a professional landscaper. While alive, walnut trees secrete juglone, which discourages the growth of many other plants.) Use your head, though; if you live in an area prone to drought and fire, DO NOT spread shavings or chips around, because they’re extremely flammable when dry.

Short pieces of solid hardwood lumber make primo kindling for those with fireplaces or woodstoves. I know—it hurts to see a piece of quartersawn oak or figured maple be turned to ash instead of a chair or stair-rail post, but it takes the chill off a sub-zero evening mid-winter (and honestly, how many years have you been storing that 2” x 2” by 24” stick in your garage?). Shorts of solid wood are also in high demand by makers of jewelry boxes and frames. If you aren’t acquainted with any people in those categories, look up your local branch of 4-H.

Small pieces of plywood bring us into more difficult waters. I have found eager takers among teachers of high-school art classes, but most of my small plywood waste goes to the landfill. You should never burn plywood, because the adhesive (and finish, if it’s prefinished) produces toxic fumes and carcinogens.

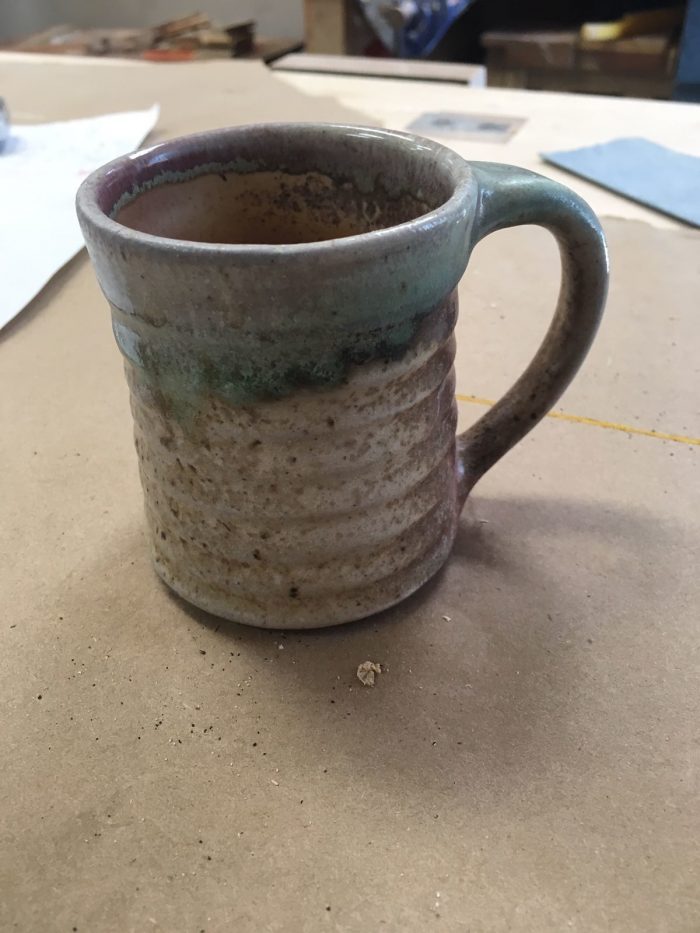

But the real payoff on this matter concerns dangerously fine dust—the stuff that’s so fine it constitutes a serious health hazard. I recently heard from a ceramic artist I know in Bloomington, Ruth Conway. I had given her a small bag of fine dust a couple of years ago, and now she was ready for more. She mixes it with clay for firing pots in her wood-fired kiln.

I collect this dust in the canister of the shop vac I use for sanding, and also in the filter cartridge of my Oneida two-stage dust collector. Ruth mixes the dust with clay to form “wadding”; three little wads of this mixture go on the bottom of each mug, garlic pot, or saucer when she fills her kiln. They allow the fire, and its heat, to pass beneath the object for complete firing. At the end of the process she simply knocks the wads loose. I was happy to learn that this stuff can have a second life (beyond the compost heap).

If you’re not acquainted with any potters who fire with wood, look up your local potters’ guild.

Nancy Hiller is a professional cabinetmaker who has operated NR Hiller Design, Inc. since 1995. Her most recent books are English Arts & Crafts Furniture and Making Things Work, both available at Nancy’s website.

More on FineWoodworking.com:

- Loose-pin butt hinges: a little play may be better than none by Nancy R. Hiller

- Business Insurance Is Non-Negotiable–Nancy Hiller’s livelihood is almost entirely dependent on her shop, and while insurance premiums are expensive she can’t afford to not pay them

- Nancy Hiller’s Reality Check(list) – If you’re thinking of turning your passion into a profession you should take a deep look at what is involved in running a legitimate business.

Comments

Nancy,

Those are wonderful suggestions - some I had not heard about. Here are my main uses for the wood chips, dust, and shavings:

- mulching - as you mentioned too. I usually mix it into the soil right away. I live in a region with high ph soils, wood chips can bring that down.

- compost needs carbon to really 'cook'. In the fall there are leaves to add but the rest of the year wood chips and dust are used.

I have also seen nesting boxes in Germany that are made fromwood chips mixed with cement. They last for decades, and contain about 75% wood chips. I think there are also other applications for wood chip concrete mixes.

I use my longer wood shavings to start my charcoals for grilling together with some cutoffs that I have no other use for.

I have a huge shavings/dust pile behind my shop that slowly has gotten larger over the years. Unfortunately, I use a lot of walnut which makes it not compatible with my wife's garden. Have looked at a couple of small, commercial wood pellet formers (as I use wood pellets to heat my shop) but still not worth the $$$ to buy. Most of the wood scraps though find their way into our wood stove.

Most of my sawdust is either softwood or maple. Either way, the sawdust is used as mulch between the raised beds in our vegetable garden. It makes for a nice spongy surface underfoot, and we never get weeds growing through it.

Offcuts that have no chance of re-use all get cut to 14" and go onto the kindling stack for our wood stove. The stack's pretty big as we rescued all framing and trim offcuts from the construction of the house, but stoves like a nice ember bed which is best achieved by not skimping on kindling!

You should check with the parents first but there are a couple kids near me that are always waiting for all my little blocks (anything under 8" or 10") to build all manner of things. A retired computer science teacher helps them with pilot holes for screws. With the kids unlimited imagination, a bottle of glue, a little paint and a hand full of pill bottle size blocks it's amazing what they can come up with. Who knows, they might become woodworkers too.

A side note about dust, the finer the more dangerous it can be. The large chips tent to fall to the floor and aren't much of a health problem but even sawing can create some fine dust that will hang in the air for a long time and find it's way deep into your lungs and sinuses if you don't protect yourself. About 10 years ago I had a mass removed from my sinuses. I had an MRI for something unrelated and my doctor saw it and sent me to an ENT. He wasn't too worried about it until I told him I had been a carpenter for the first half of my life. He sent me to a surgeon who didn't think it was cancerous but said it had to come out or I could lose the sight in my left eye. He didn't know if it was caused by sawdust exposure but went on to tell me about a sinus cancer that is and that some people develop a sensitivity to sawdust that keeps them from ever doing any more woodworking. So, wear a mask to protect yourself from cancer and sawdust sensitivity, be safe in all things and you will be able to stay out of the ER.

Log in or create an account to post a comment.

Sign up Log in