Thinking of going metric?

Guy Dunlap is experimenting with the metric system, but like many before him, he's discovering that it might be all or nothing.

After months of debate, my wife and I came up with what we wanted our new kitchen cabinets to look like. She and I both liked the clean lines of frameless cabinets and we decided that I was going to build the cabinets using the 32mm Euro cabinet system. This was a great option as there is a lot of documentation out there on building cabinets like this and the design is easy and straightforward when it comes to drawer and door sizes. The less thinking about design the better.

Now I have never had much use for the metric system in my shop, save for the times when I had to divide a number by more than two. The other issue is that I have been using the imperial standard for so long, it’s hard for me to visualize a length when I hear 280mm. So I’ve never used metric-only on a project. Until now.

I decided that since I was going to build my kitchen cabinets based on the 32mm system that I would go ahead and use only metric measurements. While that sounds easy, it actually opened up a whole new set of problems in my shop. First off, I only had a few rulers and a single tape measure that was dual metric/imperial. And of course all the machines in my shop are set up imperial, along with the marking on all my stops and fence systems. So there was a mindset and equipment issue along with all the problems of productivity when cutting the parts.

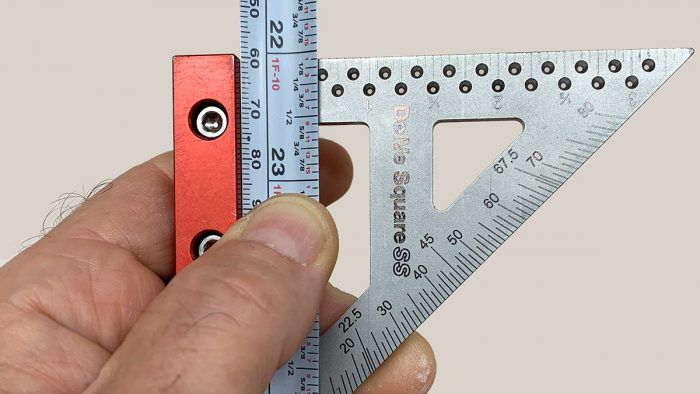

The first step was to get a new tape measure and a few new rulers that were only in metric. I fumbled around quite a bit at first, and really started to question my decision. I had a metric-to-imperial calculator on my phone that I could use to easily (or so I thought) convert the measurements on my cutlist to jive with the measurements on my tools. This proved to be a huge time suck every time I needed to set the fence when cutting a part. I quickly found another way was simply to use my dual tape measure and then use a square against it to find the correct number.

Now I was moving along a little faster. But the conversion still wasn’t tidy in every case. Since 1 in. equals 25.4mm, there was never a number that was a solid conversion that I could employ on a machine by just using the machine’s scale. So I decided to just use the tape measure/ruler to measure from whatever fence/stop I was using to the blade/bit I was using. Again, I was moving faster now.

So here is how my process went. Convert metric to imperial using the dual tape measure, set the tool I was going to use to the imperial measurement, then finalize it with the imperial-only tape rule. Now I know this sounds like a lot of extra hoops to jump through and I would be lying if I said it didn’t take extra time. It did. After a while though, I was finding that I could do quite a bit of the conversion in my head and could also start visualizing the length. This resulted in quicker setup times, and my productivity and efficiency were starting to return.

I am just about through the complete build of the cabinets and have newfound appreciation for the metric system. The plus to using metric is whole numbers, and being easily able to divide/add/subtract without any fractions whatsoever. Even a measurement of 36.5mm is easy to attain by just putting your mark between the two numbers. The only downside is the scales on my machines. It would have been nice to be able to just set it to 36.5mm instead of pretty close to 1-7/16 in.

After this experience, I am considering changing over to metric in my shop. I am not 100% sold on the idea as it would take quite a bit of time and money to change over the scales on my machines. I’m just considering it. Even though I can “see” the measurement in my mind’s eye better now than when I started the cabinet project, it still can be a little fuzzy. I do know that I will start incorporating more of the metric system into my workflow and see if I still feel this way after more time in the shop with it.

Comments

I've bought a metric measuring tape and I'd like to make the jump, but haven't done it yet. Part of it is just that I don't think in metric and I'm old enough to not embrace dealing with the transition.

On the other hand, never having to divide 17-3/16 inches by 2 or three would be fabulous. But I have an app on my phone that does that math for me now. Lazy man's solution.

I'd love to see us make the change, but I'm not holding my breath.

Metric and imperial both work well. I interchange fairly freely as I live in a metric country (New Zealand) but most of the video and plans on the web are in US imperial units.

The secret is either not converting between the systems, or doing the entire conversion in one go.

Imperial to metric is easy enough - just multiply inches by 25 - unless you are building a large ship, no-one will notice the missing 0.4mm here and there. Some common sense is needed on whether or not you round up or down - how critical the fit is will determine that.

Metric to imperial is a bit harder because you don't use decimal inches usually, though you can save some effort if you use a ruler marked in tenths of inches.

Personally I do as Guy did though - where my machines lack both measurements, just use a tape calibrated in both scales.

As a Brit, I grew up with both systems, but for woodwork only the metric system works for me and all lumber is sized in metric. Of course, I have to translate if I buy plans from FW or when I buy router bits. (Metric router bits as sold in Europe tend to have 8mm shanks - don't want that!) My advice is don't overthink it - go for near equivalents, unless there's a specific reason not to. Convention in the UK is to use 6mm for ¼", 13mm for ½", 18mm for ¾", 25 - 32 - 38 - 44 and 50. Don't go trying to measure 6.35mm or 12.7mm. You soon get used to it. As I say, the big drawback is that so many products originate from the US, so going metric is fighting against the grain in many ways.

Get a steel ruler that has both measurements. Imperial on one side and Metric on the other side...works great

As a U.S. woodworker, I'm so insulated from metric (spoiled) that I hardly ever see it. The question for my fellow yanks would be "Why bother to convert your shop?" If I spent the money, time and practice converting mindset, machines and tools to metric then every time I read an article or followed a plan or bought lumber here in the U.S., I'd have convert the measurements to fit my new metric shop. Why?

Regardless, the blog post gave me some very good tips on how to go the other way if ever I need to. Thanks for posting!

We're being forced into metric by machinery manufactured offshore, often China or Taiwan. I would be lost without dual sets of wrenches, nut drivers, hex wrenches, etc. Sometimes it's a big waste of time determining which wrench fits a particular nut. Metric nuts and bolts should all be painted orange for the unready and unwilling. But for setting up power tools such as saws, jointers, planers, routers, etc., I never rely on the built in scales because digital instruments are much more accurate. I recently bought calipers that display mm, inches in decimals and inches in fractions at the press of a button. I have a depth guage that does the same thing for setting a jointer or saw blade for depth of cut. The brand is iGage: http://www.igaging.com/.

Tables and conversion calculators are a thing of a past. How many mm in 1/32? Who cares?

I'm old enough to have started off with the imperial system here in Australia and still have a metric inch tape measure for conversions. Metric is just so much easier to work in I don't understand why the reluctance to change. The US is the only industrialised country in the world not to use the metric system

gsemon, I couldn't agree more. And it's vice versa from what user-6822566 wrote: The rest of the world is annoyed by the imperial system.

Frankly, the single best reason to convert would seem to be the ease of making calculations in the metric system. Adding, subtracting, multiplying in the imperial system seems extremely cumbersome and error-prone to me (admittedly, being European I never had to learn how). I never understood why one of the most technologically advanced countries in the world still sticks to such an inconvenient system (I know, converting would have a huge impact, but other countries have done it). To me it seems like going back from the decimal system to roman numerals. Whenever I have to make something starting from US plans, the first thing I do is convert all measures to approximately the metric equivalent as graymo explained, making sure everything still adds up.

When considering making the change, I understand the issue with your equipment still using imperial scales. For fences, you might have a look at the Wixey digital fence readout, which can be set both to metric and imperial measurements. I fitted it on my table saw (because of the digital capabilities and accuracy, not for using imperial measures) and it works really great.

We all have to deal with a mixed measuring world. In metric countries there are always remnants of the “old” ways, and in the US there is already metrics pushing their way in (think computer hardware, metric screws and fasteners). I am getting used to getting US plans and converting to metric, it’s not as easy as a calculator or mixed system rapes and rules. Buying lumber that is cut to say metric and building imperial projects and vice versa is an issue. While 3/4” is roughly 19mm it’s not exact and the little differences add up across the project.

I used to buy another US based quality woodwork magazine and either build in imperial or do the conversion myself. The same magazine is republished in Australia with all the conversions done for me, I stopped my US subscription and signed up for the Australia, I just have to wait 6+ months for the project to show up.

There is no quick, easy or thorough answer, until the imperial system is long dead, we all have to deal with it in our own way.

There was a push for the US to go metric in the mid 70’s. About the only remnants are 2-liter bottles and the occasional road sign.

Like so many things in the states, the issue became political and 40 years later, we’re still subtracting 1-5/32” from 5-1/2”.

No problem, that's 4 11/32" where's the problem? :)

I have a smart phone for that kind of thing. The rest is Imperial.

I have metric tools from working on all sorts of machinery over the years but lumber here is Imperial so no reason to change. Let each country do what it wants...

I took a different path to metric; and, am at a point where I seamlessly use both metric & imperial. My path started by going imperial.decimal - that is, getting rid of the fractional element of imperial. This was much easier than I initially thought. For me, the only mistake-evoking part of imperial was getting the fractions correct. From imperial.decimal to metric is easy. The other epiphany I had was to throw-out all but one good tape measure of each scale... no two tape measures are the same.

I was brought up on the imperial system and then converted to metric, very reluctantly, as the imperial system was so logical. A foot was the length of King Heny's foot, three feet to a yard, and a yard was the length of a Roman legionaire's marching step, and so on. Now, I would never consider switching from metric. It is so much easier and less error prone.

According to that infallible source, Wikipedia, only three countries in the world use imperial - USA, Liberia and Myanmar. And the UK still uses its imperial system for a very limited range of usages such as speed limits.

But even the metric countries still use nautical miles for navigation purposes, and measure ship, aircraft and wind speed in knots.

I took a metric class in college for an easy 3 credits. The first thing the instructor told us was never to try converting imperial to metric and vice versa. They just don't convert. I have a special calculator that is for woodworking and other things. It converts to square feet and cubic feet, or inches or yards, at the press of a button. Yes, it also does metric.

Because so much of what I use in the US is imperial, I've continued using it. But, metric is far easier to work with.

BTW, if I remember correctly, all the common plywoods in the US are actually sized metrically for thickness. This is one of the problems that all US woodworkers have to deal with when cutting dadoes and rabbets.

Americans have always been notorious for not wanting to learn other country's ways and language. Most countries are bilingual, the second being English, because American tourists won't learn even some basic words in other languages. So, why would they be willing to learn and work in Metric?

Log in or create an account to post a comment.

Sign up Log in