Make a Long Tool Rest for Your Lathe

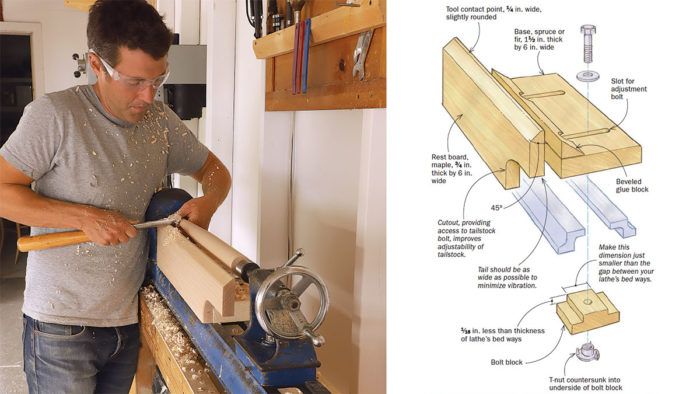

If you plan to turn chair or table legs, Tim Manney’s shopmade long tool rest allows you to make fluid, full-body motions that yield consistent, smooth, flowing turnings.

Synopsis: The short tool rests that come standard with most lathes are fine for turning short things, but if you plan to turn chair or table legs, or other long spindle work, you’ll find you have to continually stop to reposition the rest. You can avoid that with a long tool rest, and the shopmade versions shown here are inexpensive, durable, and effective. Once you’ve made one or more, you’ll set aside the tool rest that came with your lathe and you’ll never look back.

The tool rests that come standard with most lathes are generally between 6 in. and 12 in. long. A short tool rest is fine for turning small things, but the first time you try to turn a table or chair leg, or anything else longer than the tool rest, you immediately recognize its limitations—you are forced to constantly reposition it and turn your workpiece in 6-in. to 12-in. segments. All this stopping and starting prevents you from making the fluid, full-body motions that yield consistent, smooth, flowing turnings.

You can buy commercially made tool rests 24 in. and longer; they’re typically made of iron in a double-post design. And they are nice to use, but they can be hard to find and are usually pricey. Instead of going that route, I made three simple wooden tool rests in varying lengths, and I use them for all my spindle turning. Each tool rest cost less than $10 in materials and took about one hour to build. once I’d made them, I put the tiny rest that came with my lathe in a box; then I forgot where the box was. Good riddance.

Curtis Buchanan taught me to turn during a fall and winter that I had the good fortune of working with him in his Windsor chair shop in Tennessee. My tool rests are based on the ones that Curtis uses. however, lacking the thick maple butcher block that Curtis used as the base of his rest, I came up with a slightly different construction method for mine, designing a rest that’s easy to build from common materials.

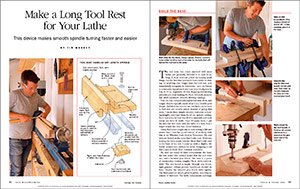

My rests are made of three components: the base, the rest board (the vertical board that the tool rides on), and a beveled glue block. The base is a piece of construction lumber roughly 1 1/2 in. thick and 6 in. wide. The rest board is maple (though any dense, tight-grained, diffuse-porous hardwood should be fine). Finally, the beveled glue block adds rigidity. The three parts are simply glued together, requiring no joinery or fasteners. The hefty components and large glue surfaces create a rigid, vibration-free tool rest.

From Fine Woodworking #279

To view the entire article, please click the View PDF button below.

|

|

|

|

|

Fine Woodworking Recommended Products

Milescraft 4007 6in Bench Clamp

Hedgehog featherboards

CrushGrind Pepper Mill Mechanism

Comments

The only change I would make would be to add a 1/4"thick x 1" metal strip into the top edge. I would project it about 1/2"out of the wooden upright.

This gives one a more sturdy edge to work from and one that can be filed to smooth out any dings that result from catches. The metal should have a bit of bevel on the top edge.

Log in or create an account to post a comment.

Sign up Log in