Liquid Hide Glue – My Favorite Sticky Stuff for (Most) Woodworking

In her blog, Megan Fitzpatrick details why she uses liquid hide glue in about 90% of her interior woodworking, and it's not just because of the longer open time.

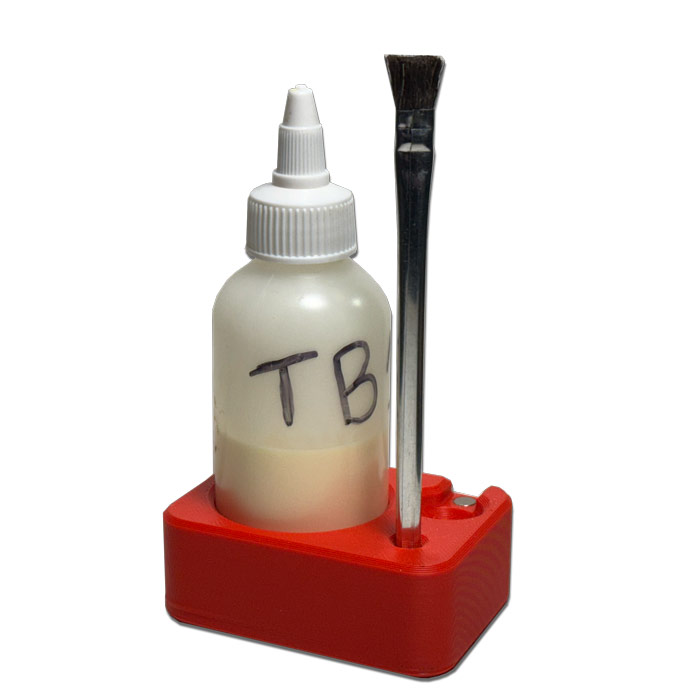

I use liquid hide glue in about 90% of my interior woodworking. I use it on any carpentry work in my house that requires adhesive, on furniture-sized projects in the shop, and on shop projects that are the size of a tiny house (see the tool chest above). Yet when I pull out the bottles of Old Brown Glue (OBG)or Titebond’s liquid hide glue (TLHG) during classes, students often stare at me as if I’ve started performing the prologue of Henry V (bewildered and not a little dismayed).

I get it; it’s not the wood glue you find easily on the shelves at the big box stores. Though animal-based glues were used almost exclusively for most of material history, in the mid-20th century, polyvinyl acetate (PVA, aka yellow and white glues) became king, and now there are many other alternatives as well (epoxy, polyurethane, cyanoacrylate, to name three), all of which are easy to find. Finding liquid hide glue can take some effort, but it’s worth it. Two independent hardware stores near me carry the Titebond, but for Old Brown, I have to go to a woodworking specialty store or order online.

I think hide glue gets a bad rap. It has a relatively short shelf life. It also takes foresight to soak pearls or flakes in water overnight, and then you need a double boiler of some sort to prepare it. Most often, I hear people say that it stinks. While it’s true that hot hide glue emits an odor, if it’s not rancid, it doesn’t smell much different from beef stock. I can detect little smell from the bottled liquid stuff. And while hot hide glue does indeed take a bit of time and equipment, liquid hide glue can be used straight from the bottle – though you do have to drop the Old Brown Glue bottle in hot water to make it flow (ditto with Titebond if the shop is below 70° or so). It does have a short-ish shelf life, I guess: two years. I go through a couple bottles of liquid hide glue in any large class, so this is a non-issue for me. (And if you store it properly in a cool, dry place it lasts longer.)

So why do I prefer liquid hide glue to PVA and other modern glues? Well, I guess I’m just slow. And I like to offer as much time as possible to my students during glue-ups.

Liquid hide glue has longer open time than PVA – 10 minutes (compared to around 5 for PVA), with a total assembly time of 30 minutes or so (a bit more in a cold shop). With PVA, joints need to be fully seated more quickly, and the clamps need to be be cinched down within 10 to 15 minutes. One advantage of PVA is that the clamps can come off after about 30 minutes (as long as you don’t stress the joints), which is great when you have more glue-ups than you have clamps. With liquid hide glue, I’m loathe to take the clamps off in less than an hour, and I’d rather leave them in place overnight.

Liquid hide glue and hot hide glue are easily reversible with the application of water and steam, so if I have to make a repair, it’s not too much trouble to take a piece apart. Plus, hide glue dissolves into itself; you don’t have to remove all the glue to apply more. With PVA and other glues, you have to get off all the glue before adding more—and you’re awfully likely to remove some wood with it, changing the shape of the workpieces.

Hide glue interferes less with finishes. PVA can leave a white splotch that you won’t find until the finish goes on. You can get away with some clear coats (oil and varnish, shellac, lacquer) over a splotch of hide glue (though it’s still good practice to clean it all off before finishing). Caveat: You can paint on a thinned coat of hide glue under milk paint to create a crackle finish…even if you don’t mean to. (Found that out the hard way.)

Cleanup of hide glue is easy. Just scrub it with hot water, even after it’s been dry for years. It comes out of my clothes in the wash, and out of my hair (which often ends up as an unintended glue brush) in the shower.

And while I don’t have scientific evidence that it’s as strong as PVA, in my experience, it’s plenty strong enough.

For the record, I prefer Old Brown Glue to the Titebond liquid hide glue; it has fewer ingredients, and Patrick Edward makes it in a spare bathroom (what can I say – I find that charming). As we determined in tests years ago at my former magazine, the OBG reverses more cleanly and quickly than the Titebond, and it tacks in a “rub joint” application (the Titebond doesn’t). Traditional hot hide glue works best for rub joints, especially when you need it to grab quickly, as in veneer work or installing glue blocks. But I don’t usually have to reverse joints and I’ll heat up the hot stuff for rub joints, and I don’t like driving the 20 miles to the woodworking specialty shop (a trip that involves battling trucks on I-75 and mall traffic).

I did eschew hide glue in favor of Titebond III on a bathroom cabinet I recently finished. As I mentioned, heat and water reverse hide glue, and I like hot showers.

Fine Woodworking Recommended Products

4-oz. Glue Bottle - 3 Pack

Bessey Band Clamp

Bessey EKH Trigger Clamps

Comments

Another bonus is how slippery it is. Dovetails that would need serious persuasion with PVA just slide together with the Titebond liquid hide glue.

I am also a liquid hide glue aficionado. I use it on anything that doesn't need to be water resistant/proof for pretty much all the reasons you called out. I especially love the simple cleanup and the fact that it doesn't block finishes after cleanup.

Log in or create an account to post a comment.

Sign up Log in