Bulk Up Your Benchtop Lathe

A sturdy stand with a bed extension and sand for ballast lets a bantam lathe function like a heavyweight.

When I set up my first workshop, I bought small, homeownergrade machinery that was manufactured between 1930 and 1950. The shop was in a rented space, and I knew I would have to move at some point. The machines I bought were stout and of good quality, and their diminutive size meant I could pick them up by myself, put them into the back of a small pickup, and set them up in a new space without having to hire a rigging crew or recruit the help of a horde of friends. They also take up minimal real estate, a benefit in small workshops.

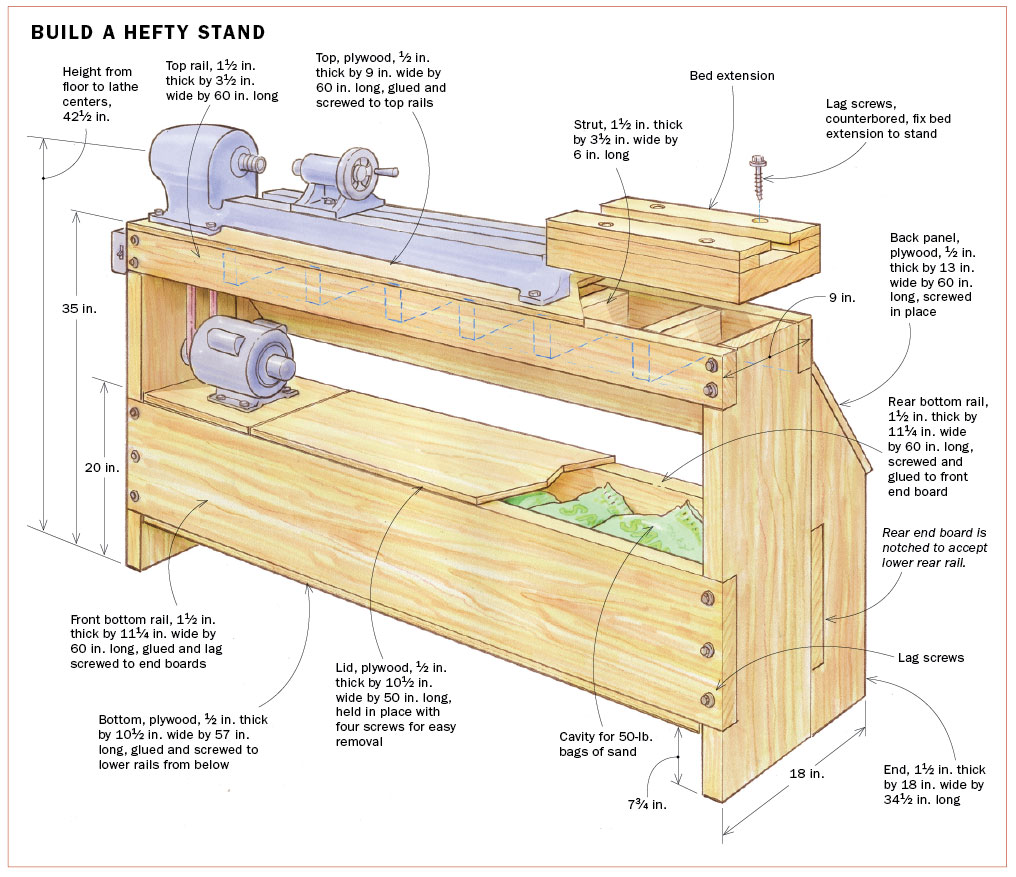

The disadvantage of smaller, lightweight tools is that they are more prone to vibration and chatter than their counterparts that weigh hundreds of pounds. I compensated for that by making stands for those tools, stands that are robustly built and incorporate shelving or boxes that I can fill with 50-lb. bags of sand. When it is time to move I take the machine off of the stand and move the machine, the stand, and the sand separately.

My lathe stand is a good example of this approach. The lathe is a 1938 Craftsman model that weighs less than 100 lb. The stand is built sturdily with construction lumber and a few plywood panels that make for a rigid assembly. There is a box in the frame that holds 150 lb. of sand to help deaden vibrations and keep the lathe stable when I’m roughing down large spindles.

The height of your stand will vary depending on your height and the height of your lathe centers. I am 5-ft. 5-in. tall, and I built my stand so that my lathe’s centers are 42 1/2 in. from the floor, which puts the centers at the height of the crease of my elbows when I stand with my arms by my sides. Turning at this height is comfortable for me.

If I were building the stand again, I would make cutouts on the bottoms of the end panels to create feet so it would be easier to shim the stand to match an uneven workshop floor. I would also increase the width of the sand compartment so bags of sand would fit flat in the box rather than on edge. This would let me double the amount of sand in the base from 150 lb. to 300 lb.

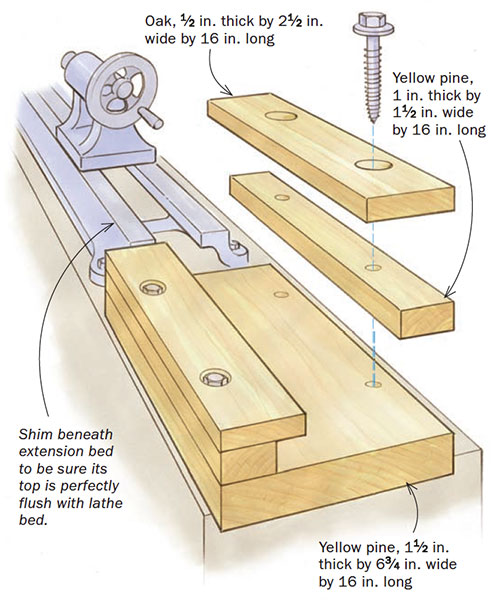

I built my stand longer than the lathe and added a bed extension so that I could turn the long rear posts of my ladderback chairs. I built the extension bed out of scrap, and I have always meant to go back and build something a little more stable and durable, but it works fine and I just keep using it. When I lag-bolted the extension bed to the stand I shimmed beneath it with business cards to bring it perfectly into alignment with the lathe bed.

This is an excerpt from Tim’s article Make a Long Tool Rest for Your Lathe in Fine Woodworking issue #279

|

|

|

|

|

Fine Woodworking Recommended Products

CrushGrind Pepper Mill Mechanism

Comments

Confused as to how the rear 9" board is attached, though I suppose it's not supporting any real weight so it's not the most important part.

It's glued.

Log in or create an account to post a comment.

Sign up Log in