The first piece of “real” furniture I built was a kitchen table. I was newly married and we needed one. I remember working with my dad one day, clearing out a tobacco barn in Hadley, Mass., when we came across a small stack of rough-sawn boards up on the third floor. At first glance they didn’t look that special, but when I swiped away the generous coating of dust, they turned out to be very beautiful black walnut, most likely put there many years ago by the original owner of the farm after cutting down the tree on his property. I didn’t know much about what made certain woods good for woodworking, but my dad told me walnut was nice and said I could buy the pile for $40. So at lunchtime I tied several pieces to the nearby antique grapple and lowered them down, batch by batch.

It’s fun to think back on that table project, because at that point everything about woodworking was so new, and I didn’t know what I didn’t know. The only power tools I owned were a circular saw, a jigsaw, and a gigantic Black and Decker cordless drill. For hand tools, I had a few planes, a 26-in. panel saw, and random chisels, all fairly rusty. I loved the idea of using hand tools but I didn’t know much about how to use them. I knew enough to start by flattening the boards, but I didn’t know how to sharpen a plane blade, never mind read grain direction. I heard somewhere that splines would make the top stronger so I found some small maple strips (each a different size) and cut a groove to fit them between the glue joints on the top boards, which I left the full 1-1/2 in. thickness that I found them. I managed to cut eight ill-fitting mortise-and-tenon joints using a cordless drill and chisels for the mortises and then awkwardly wielding the panel saw for the tenons. I have a foggy image of tapering the legs with the circular saw, a clamp, and a sawhorse. Yikes. Then it was back to the cordless drill to make holes for pegs.

My wife and I used that table for about 12 years. It was extremely satisfying to know I made it with my own hands and it was fun to know where the wood came from. The building mistakes were forgotten and it turned out it worked really well at holding any object placed on it about 30 in. off the floor. One leg developed a weird twist (from not paying attention to grain direction when choosing parts), the top was weathered with water marks, dings, dents, and scorches (it doubled as an ironing board), but that table was still solid years later when we handed it off to newly married friends who needed a kitchen table.

I share this story, and these four articles that address fixing mistakes, to encourage any new woodworkers to worry a bit less about making mistakes. Just start woodworking where you are and use what you have. To build a piece of furniture that can be used in daily life is a great joy. It turns out woodworking is just like life: When we make mistakes, we grow.

—John Tetreault

Deputy Art Director, Fine Woodworking

|

Dealing with Woodworking MistakesTo err is human, but clever repairs are divine Issue 95, July/Aug 1992 by Sandor Nagyszalanczy |

|

When Mistakes HappenHow to fix dings, cracks, splits and more without starting over. Issue 147, Jan/Feb 2001 by Jeff Miller |

|

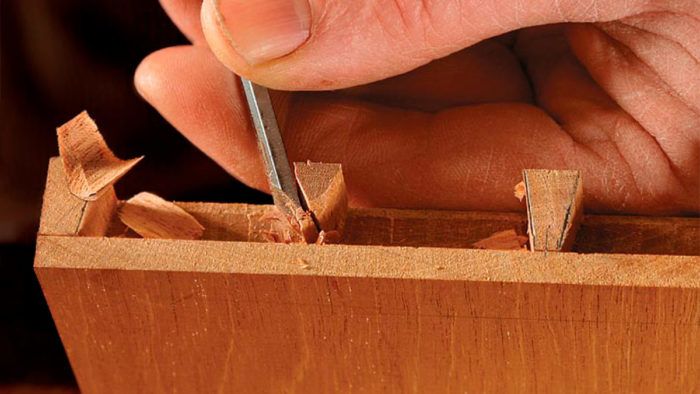

Seven Joinery FixesDon’t scrap a valuable workpiece; make an invisible repair. Issue 186, Sept/Oct 2006 by Philip C. Lowe |

|

How to Fix Flaws and MistakesInvisible repairs that will save you from starting over. Issue 228, Sept/Oct 2012 by Mark Schofield |

Log in or create an account to post a comment.

Sign up Log in