Dovetailing on the Table Saw

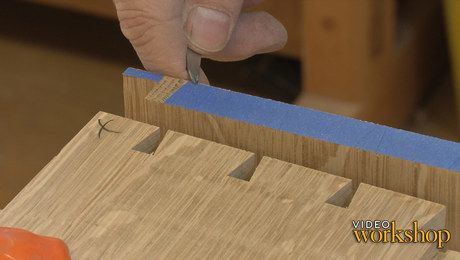

Mike Pekovich demonstrates how to cut tails quickly and efficiently on the tablesaw using a sled and a custom-ground blade.

Start your 14-day FREE trial to watch this video

Plus, access more than 500 video workshop episodes when you become a member

Through-dovetailed case, through-mortise-and-tenons, half-blind dovetailed drawer, frame-and-panel door, and a beautiful kumiko panel–Mike Pekovich’s hanging wall cabinet video workshop packs a lot of techniques into a small piece.

In this episode, Mike begins his dovetailing master class at the tablesaw, where he creates the tails quickly and efficiently using a sled and a custom-ground blade.

Videos in the Series

-

Ep 1: Hanging Wall Cabinet with Mike Pekovich–IntroDecember 17, 2019

-

Ep 2: Laying Out and Rabbeting the CaseDecember 17, 2019

-

Dovetailing on the Table SawDecember 24, 2019

-

Ep 4: Hand-cut pins with a twistDecember 31, 2019

-

Ep 5: Fitting the dovetailsJanuary 7, 2020

-

Through Mortise-and-Tenon LayoutJanuary 14, 2020

-

Ep 7: Drilling and chopping mortisesJanuary 21, 2020

-

Ep 8: Cutting the tenonsJanuary 28, 2020

-

Ep 9: Prefinishing and gluing up the caseFebruary 4, 2020

-

Ep 10a: Making the door frameFebruary 11, 2020

-

Ep 10b: Creating the door panel and dry-fittingFebruary 11, 2020

-

Ep 11: Sizing the kumiko gridFebruary 18, 2020

-

Ep 12: Door glue-upFebruary 25, 2020

-

Ep 13a: Fitting the doorMarch 3, 2020

-

Ep 13b: Mounting the door hingesMarch 3, 2020

-

Ep 14: Door detailsMarch 10, 2020

-

Half-Blind Dovetailed Drawer – part 1March 17, 2020

-

Half-Blind Dovetailed Drawer – part 2March 17, 2020

-

Drawer Grooves and Glue-UpMarch 17, 2020

-

Ep 16: Shiplapped back boardsMarch 24, 2020

-

Ep 17: Fitting the drawerMarch 31, 2020

-

Ep 18a: Kumiko–Asa No Ha pattern part 1April 7, 2020

-

Ep 18b: Kumiko–Asa No Ha pattern part 2April 7, 2020

-

Ep 18c: Trimming a kumiko panel to sizeApril 7, 2020

-

Ep 19: Simple shellac and wax finishApril 14, 2020

-

Ep 20a: Installing the shelf supports and hardwareApril 21, 2020

-

Ep 20b: Installing a bullet catch–ConclusionApril 21, 2020

Comments

I can appreciate that using the tablesaw to cut the dovetails is pretty fast compared to hand cut. However, where does one get a specially ground blade? And what if you want to do something other than the 8.5°, do you get multiple blades ground? Seems to be a pricey thing for a hobbiest.

I can see shares in the 8.5degree saw blade company skyrocketing.

You can buy that blade straight from Forrest. Or you can buy a FTG blade and have it sharpened that way. I think most of the time people just use one bevel angle.

It's not that expensive to get them ground. And it's a good use for the stock saw blade that comes with your saw. Most folks upgrade their blade to a Forrest or a thin kerf.

LOL - Forrest website is already saying they have an unexpected increase in demand. The new Pekovich Effect

Hello Mike thanks for the table saw dovetail demonstration. Looks like a cool way to get an accurate dovetail with a narrow opening on the tail. unlike the tail opening on a router cut tail.

https://www.forrestblades.com/saw-blades-for-finger-joints-square-cut-box-joints-rabbets-grooves-and-dovetails/10-custom-woodworker-ii-saw-blade-for-dovetail-cut-40-teeth/

Yes, as predicted ... “Please Note before you place your order: Due to an unexpectedly high volume of orders, you may experience a shipping delay. We will notify you of your expected shipping date after we process your order.”

I hope Mr P is getting something for his sales assistance: I will just have to go to my local blademaster in Townsville should I feel the need.

I messaged Mike to see if he would recommend 8.5 degrees or if he would pick a different angle blade and this is what he said.

"I ordered an 8 degree blade, but it turned out closer to 8.5, which is not a problem. It's a somewhat shallow angle because I cut a lot of dovetails in thicker casework. A school I teach at has 10 degree blades which are fine as well."

After doing some research online I've found pictures showing the difference of angles with their respective ratios.

10 degrees = 1:6

12 degrees = 1:5

14 degrees = 1:4

By that logic 8 degrees would be 1:7 which as Mike said is slightly shallow. Most dovetail guides offer 1:6 for softwoods or 1:8 for hardwoods.

*Picture credit to David Barron Furniture

I have always wondered why Forrest produces this blade in a ten inch configuration. It could easily be made from an eight inch blank because you're not making a very deep cut with it. A smaller blade might save a few bucks - less material, fewer teeth.

As an alternative to dropping $166 for the Forrest model, some years ago I used a diamond wheel on a Dremel to roughly fashion the beveled teeth on an old 7-1/4 inch blade I had for a circular saw. It actually worked pretty well, and I used it for a number of dovetailed drawers.

Zolton

Thanks Mike for the dove tail technique.

Ridge Carbide Tool Co also makes a dovetail saw blade. Delivery was quick. Ordered on line, Ridge called the next business day to be sure I wanted right tilt (yes old Unisaw). 3 days later the new blade arrived to the angle requested and I am building a dresser with Mike’s techniques

Where did you get that multi dividers. I check Garrett Wade and Lee Valley couldn’t find it. But if you ask my wife I never Can find anything.

The closest I can find is the M-Power point 2 point. https://www.m-powertools.com/point-2-point-mk2-layout-divider.html

Rockler is now (9/2022) carrying it :

https://www.rockler.com/m-power-point-2-point-mk2-layout-tool?country=US&sid=V91040&promo=shopping&utm_source=google&utm_medium=cpc&utm_term=&utm_content=pla&utm_campaign=PL&gclid=EAIaIQobChMI987K8fj9-QIVTWxvBB1rcQegEAQYAiABEgLIuPD_BwE

Thank you those will work fine

A cheaper alternative to the Forrest blade is to buy a flat-top rip blade and have it sharpened to the angle you want. I just bought a thin kerf Freud blade for around 45 dollars that I plan to have ground for skinny dovetail pins.

I've got one from old Bridge City Toolworks. The new Bridge City Toolworks does not seem to have one. I found one for $11 on Amazon by searching "dividers" in "tools and home improvement." The search for multidividers didn't find it, but found dozens with cutting wheels on them for bakers. Apparently crust strips is a thing.

My local sharpener charged $25 to grind a Freud 8" full kerf rip blade at a ten degree angle, which cost $50. Just make sure to specify left or right tilt TS. Also, I think you need to be careful when using anything but a 10" blade on a sawstop.

Another alternative is the “DCT equal space divider”, if you search for this you can find it on multiple shopping sites for about 30 dollars. I didn’t post a link because I don’t want to choose one vendor over the other. The advantage of this one over the MK2 is 4 nuts vs 2.

Mike: I'm mystified about why you left the tiny nibs in the gaps between the tails. These could have been removed by offsetting the board a trifle and making an additional pass over the blade.

I use the technique, but have not bothered with the beveled tooth blade. I simply set the depth 1/16" low and chop out the waste to the base line. I usually hand cut dovetails, so its not a significant chore.

For cutting small box joints, I had an old 60 tooth blade reground flat. Rip blades are ground flat, but the 60 tooth gives me perfect cuts without any splinters. I recall the cost being $17, as he didn't need to sharpen the blade.

Log in or become a member to post a comment.

Sign up Log in