Ep 4: Hand-cut pins with a twist

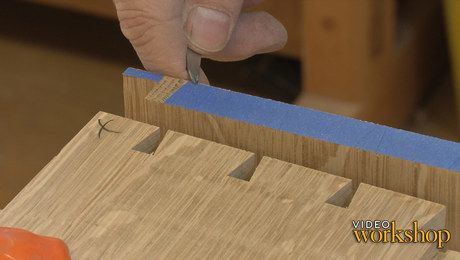

Behold the power of blue tape! Mike's dovetailing master class continues as he demonstrates his now famous method for cutting consistent and precise pins by hand.Videos in the Series

-

Ep 1: Hanging Wall Cabinet with Mike Pekovich–IntroDecember 17, 2019

-

Ep 2: Laying Out and Rabbeting the CaseDecember 17, 2019

-

Dovetailing on the Table SawDecember 24, 2019

-

Ep 4: Hand-cut pins with a twistDecember 31, 2019

-

Ep 5: Fitting the dovetailsJanuary 7, 2020

-

Through Mortise-and-Tenon LayoutJanuary 14, 2020

-

Ep 7: Drilling and chopping mortisesJanuary 21, 2020

-

Ep 8: Cutting the tenonsJanuary 28, 2020

-

Ep 9: Prefinishing and gluing up the caseFebruary 4, 2020

-

Ep 10a: Making the door frameFebruary 11, 2020

-

Ep 10b: Creating the door panel and dry-fittingFebruary 11, 2020

-

Ep 11: Sizing the kumiko gridFebruary 18, 2020

-

Ep 12: Door glue-upFebruary 25, 2020

-

Ep 13a: Fitting the doorMarch 3, 2020

-

Ep 13b: Mounting the door hingesMarch 3, 2020

-

Ep 14: Door detailsMarch 10, 2020

-

Half-Blind Dovetailed Drawer – part 1March 17, 2020

-

Half-Blind Dovetailed Drawer – part 2March 17, 2020

-

Drawer Grooves and Glue-UpMarch 17, 2020

-

Ep 16: Shiplapped back boardsMarch 24, 2020

-

Ep 17: Fitting the drawerMarch 31, 2020

-

Ep 18a: Kumiko–Asa No Ha pattern part 1April 7, 2020

-

Ep 18b: Kumiko–Asa No Ha pattern part 2April 7, 2020

-

Ep 18c: Trimming a kumiko panel to sizeApril 7, 2020

-

Ep 19: Simple shellac and wax finishApril 14, 2020

-

Ep 20a: Installing the shelf supports and hardwareApril 21, 2020

-

Ep 20b: Installing a bullet catch–ConclusionApril 21, 2020

Comments

Mike,

You are one of the few that points out the hardest part of cutting dovetails has nothing to do with sawing. It is aligning the boards to knife around the tails. It seems and sounds so simple but it is challenging to remain square and get the boards aligned so the pin is not too big or small.

I'm curious if you have experimented with cutting a rabbet in the tails to register the tail board to the pin board, either with a skew block plane or machine?

Shaun

Okay. I have watched the first four fantastic videos. Mike is a great instructor and doesn't leave the viewer with many questions.

The one question I have is - when is the next video?

Norm

We release one episode (or group of episodes) every Tuesday.

Hi Shaun, Yes, this technique is based on cutting a rabbet in the tails board to help with alignment. The rabbet works well but can present its own problems. Namely, it throws off the shoulder to shoulder dimension by thinning the stock at the joint. In some cases that’s not a problem, but in this particular project it is because it would require a different shoulder to shoulder length for the shelf and that throws of the efficiency of starting with like-sized parts. The shoulder guide performs the same task without altering the dimensions of the parts which is why I like it. Also, and I don’t think I mention it in the video, by shifting the guide forward or back from the scribe line, you can alter the fit of the joint. On soft woods like pine drawer sides, I can intentionally create a too-tight fit by positioning the guide slightly below the scribe line to accommodate compression. Cool stuff.

In your defense Mike, you mention that when dovetailing the drawers later in the series.

I’ve used that bandsaw technique for a long time but silly me, I just cut several fingers to make chiseling easier, without thinking I could actually cut more of the waste at the same time. D’oh!

I’m still not sold on grabbing my router to finish things off but I’ll wait for Mike’s next video, maybe I’ll change my mind. I like my chisels and routers are loud and messy, but I also like perfect dovetails. I’m pretty sure Mike has made a lot more of them than I have. Thanks Mike, good book by the way :)

Thank you!

Agree on the shoulder to shoulder length which for the cabinet would be an issue for your middle shelf.

Thanks. Great video series!

There is such beauty in simplicity. As simple as Mike Pekovich's blue tape technique is, it gives beautiful results. I am making a china cabinet using the half-blind mitred dovetails featured on Chris Gochnaur's "contemporary sideboard." I had completed two of the four corners of the case before watching Mike's video featuring blue tape. His advice enabled me to solve the single biggest problem I was having with this complicated joint - namely, seeing the pin's lay lines. It made an enormous difference to my confidence while sawing and resulted in a much more precise fit, with significantly less paring prior to the joint coming together. Sending a big thank you to MP, CG, and the FW staff for making it possible for wannabes like me to learn how to build fine furniture.

Hello, thanks for the great video! I am curious if there are any plans for this project available? I am curious about the width (depth?) - Meaning how far off the wall it will sit?

The plans are available on this page: https://www.finewoodworking.com/videoworkshop/2019/12/hanging-wall-cabinet-with-mike-pekovich

Nice camera work. Closeups that show what is really going on.

Is there a reason that you do not gang up the side boards to cut them? When hand cutting, we do that all of the time.

Complementary to the blue tape "trick": make sure the ends of your boards are smooth before doing any kind of precision marking. A no-brainer in hindsight, but I spent years trying to get accurate pencil lines on rough ends. Now a pass with 220 sandpaper on a rigid hardwood scrap sanding block makes the layout easy and accurate.

Lot of great teachers on FWW staff and contributors, and Mike is one of my favorites. Hope he keeps his teaching hat on as he moves up to editor.

I have two thinnish pieces of pine, dovetailed into a 90° reinforced with a corner piece of ply which when the down piece is in the vice the ply hits and registers with the side of the bench. To align the pieces I line up whichever edge makes sense with one edge of 90° and clamp the piece to it. If the edge is in line in one piece it's in line with the other.

They are long enough to get things square by lining up the edges as well. As for seeing knife lines or knowing which is the waste. I use a thin propelling pencil to darken the line (2B lead) then hatch the non waste. I have no trouble knowing which side of the line to cut on or pare to.

Set up takes very little time. I can lay my hands on the jig very easily.

BTW blue tape looks to be what we on the other side of the pond call masking tape. Available in different levels of stickiness, you use the low tack stuff for newly painted walls for eg.

I pencil in my knife lines pretty routinely. My pencil sits in a hole in the shelf just above the bench, behind the marking knives (scary sharp).

to align the tails and pin, I use a pair of right angle clamps. It doesn't move and you can pick up the whole thing to look for any problems. Sure makes it easy!

There are many techniques and tools for getting your dovetails crisp, clean and tight, and I've reviewed, studied, tried most of them. So many of them sound great until you actually try them out at your bench. I keep coming back to Mike's simple, cheap and effective alignment jigs. Yes you can use the popular technique of routing a shallow alignment rabbet in the tailboard to help with alignment but, in addition to the issues mentioned by Mike above, cutting said rabbet accurately is in itself a task requiring skill, time, and additional tools.

I keep aspiring to develop the skill of accurately cutting on the correct side of the scribed layout line, but if I can't see that line clearly, I pull out the blue tape.

Regardless of technique and tools, the most important element of creating front-cover-worthy dovetails is practice, practice, and 'mo practice.

Two things I noticed with the square alignment block that would be helpful to know beforehand:

1. Mike has a deeper than normal bench, the lipped block is designed to sit at the rear of the tail board with the lip along the back edge. This does not work on a shallower bench so when you make your square stock just cut out two pieces and attach the lip to one but not the other. You can then place the non-lipped square toward the rear of your bench with the tailboard hanging over.

2. The block should raise the piece enough that the spring clamp used to hold the depth alignment jig in place can fit between the tail board and the workbench. For me lifting the piece 2 inches off the bench was enough, but 1.5 was not.

Log in or create an account to post a comment.

Sign up Log in