Dust collection: Our favorite articles

The articles found in this collection cover all facets of dust collection–from finding the right dust collector to getting the most out of your current collector, from organizing your shop for efficient dust collection to designing a ductwork system.

It’s easy to think of dust collection as a “nice to have.” After all, sweeping up sawdust with a broom works to keep the shop clean, and you don’t mind being covered in sawdust after being in the shop all day. However, the more time you spend in your shop, the more likely it is to become a “must have.” In fact, dust collection has become less about a clean shop and more about safety. Not only does proper dust collection keep sawdust off the floor, it keeps it out of the air, and in turn, out of your lungs and out of your eyes.

The articles found in this collection cover all facets of dust collection–from finding the right dust collector to getting the most out of your current collector, from organizing your shop for efficient dust collection to designing a ductwork system.

All About Dust Collection

Collecting and exhausting dust at its source, before it reaches you, is the most efficient way to deal with wood dust. That’s why woodworking machines—from tablesaws to disk sanders—come with exhaust hoods or ports. “A typical exhaust hood,” industrial hygienist Richard Supples of Applied Improvement Technologies in Shelton, Conn., explains, “creates a capture velocity and effectively ‘grabs’ the dust particle and transports it through a duct/filter away from the worker.”

by Asa Christiana

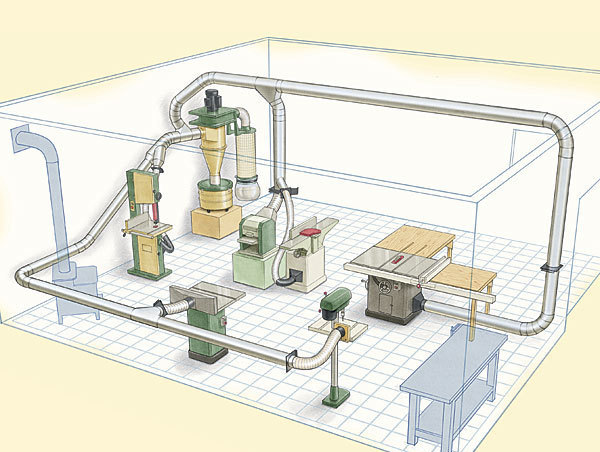

Step Up to Whole-Shop Dust Collection

This article offers a number of tips on setting up a rigid-duct system for home woodshops. Large-diameter, smooth-walled rigid ducting generates less friction than flexible corrugated hose and brings powerful suction to every power tool in the shop. Upgrading to a solid-duct system isn’t cheap—adding it to a 600-sq.-ft. shop could cost more than $1,000. And it might take a few days to put it all together. But when it’s done, you’ll be putting more dust in the collector and less in your lungs.

by Randall Shuh

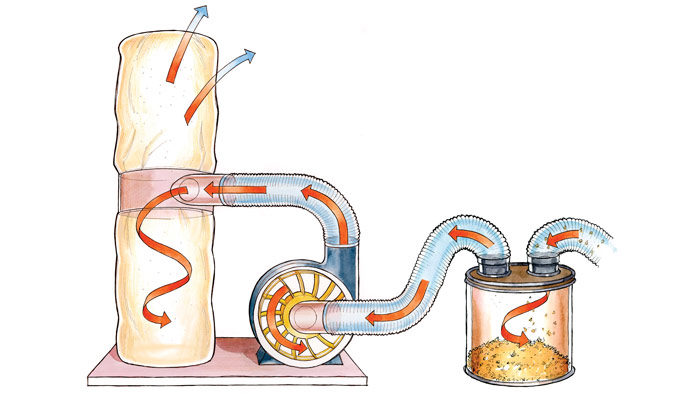

Everyone agrees that wood dust is a danger, but not everyone can afford the best solution, a cyclone dust collector with state-of-the-art filtration. So what do you do for more budget-friendly protection? Add a better filter and a separator or internal baffle to your single-stage collector. Better filters will filter the finest dust, keeping your airways cleaner, and a separator or baffle will trap the majority of dust before it reaches the filter, so you won’t have to stop and unclog it as often.

by Bill Peck and Asa Christiana

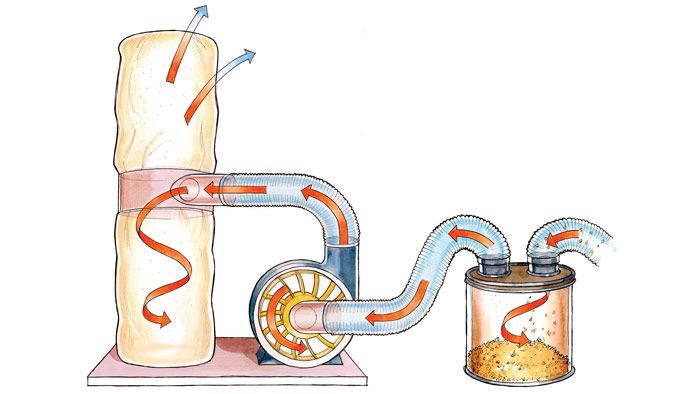

A dust collector performs an urgent and challenging task in the woodshop–it keeps the dust and chips produced by woodworking machines out of the air, off your tools and floor, and as a result, out of your lungs. This article aims to take the mystery out of choosing between a single-stage collector and two-stage cyclone collector. Both types will do the job if connected to the right setup of hoses and ducts. A test of the capacity of each type of collector gives guidelines on which type of system will best suit your needs, and gives suggestions for laying out ductwork in your shop.

by Steve Scott

A Revolution in Dust Collection

The trouble with wood dust is that the most dangerous particles—the very fine ones—are the most difficult to collect. Under 10 microns in size, they hang longest in the air, penetrate deepest into the lungs, and are the hardest for the body to eject. Our corner of the woodworking world has been slow to tackle the problem of adequate dust collection, but more and more manufacturers are getting serious about the subject, and effective solutions are now available for every size shop. Learn the differences among the cyclone, the single-stage dust collector, and the shop vacuum, how to choose the right filter, and how to use a dust separator to make your system the best it can be.

by Asa Christiana

Fine Woodworking Recommended Products

Rockler Dust Right 1250 CFM

JessEm Mite-R Excel II Miter Gauge

Ridgid R4331 Planer

Comments

It's a large subject, workshop dust. This article needs a few more pointers and references perhaps.

I recently moved house (and workshop) so took the opportunity to reorganise some aspects not dealt with in the previous workshop, including better dust control. The first thing was to replace a 1hp main extractor with a 3hp model. That's made a large difference, as witnessed by the dust-free surfaces in the new workshop compared to the always dusty surfaces of the old. Many machines overwhelm a 1hp extractor.

Every other dust generator has had the suck that's applied to it improved too. This was not so much via replacement of any of the three small vacuums available to me but rather by connecting everything to them on all occasions. No "saving a minute" by not bothering.

The hand sanders now have a hose attachment to a vacuum - an Abranet sanding pad with it's associated connectors and hose. The router table and table saw have dust collected from both above and below their tables. Even the drill press has a magnetic sucker mouth stuck adjacent to the bite-point.

There's often a comment in magazines that hand tools don't really generate dust. In fact, planing and other hand tool actions can generate dust from some wood species. It's usually very fine - too fine to see. But consider a more obvious hand tool dust generator, the scraper.....

Another dust dealing aspect is to exchange the air in the workshop fairly quickly. Unfortunately this can mean cooling or dampening the air. At the moment, I'm looking at a heat-exchanging in/out fan gubbins. But these are expensive and not good with dusty air....

Lataxe

Most of the photos included in these articles unintentionally demonstrate the point that having a lot of hoses and ducts around the shop can be a major trip hazard. They can greatly impede work flow of the shop, and tripping and falling into a cast iron machine with a spinning blade can really put a damper on your whole day.

I designed my shop with the collector unit outside. It keeps the noise outside, saves space in the shop, and makes emptying the dust bin much easier.

All the duct lines go straight up from their tools, run across the ceiling, and out thru the wall to the collector. Even the choice of the drop down points has to be considered so that the ducts do not block lumber from moving from one task to another.

This magazine has lots of great articles about shop layout, and how to configure the floor plan to optimize workflow for the type of work being done and the tools in the shop. The dust collection needs to be included in the very first step of that design process. Not something that is stuck in later.

Golden,

Those many hoses are a trip hazard, as you say. The first photo has an arrangement that looks particularly hazardous, with the hoses placed just right to cause the tumbling woodworker to test the resilience of those many cast iron tables with a head. Perhaps those using that 'shop should wear crash helmets? :-)

Interesting about putting your dust sucker outside. Does this compromise the shop's heating and cooling to any significant degree? Mine moves (theoretically) 3450 m3/hour (2600CFM) of air so would throw out any workshop heat in no time unless a heat exchanger was put somewhere in the line.

On the other hand, the dust sucker takes up a significant chunk of the small floor area of my one-garage 'shop....... It would be nice to have that space for me instead. And less noise.

I did consider one of those always-on air filtration boxes to add to the dust-dealing gubbins. But it seems that the big dust extractor serves that purpose as well - at least when a machine is running. In all events, surfaces don't collect a film of dust over time, as they did in my previous 'shop.

Lataxe

I just finally got around to installing the mini split heater/AC unit, so I'll have to see how much the dust collector pulls the heated or cooled air out of the shop. I'm sure it does to some extent. But even so it seems like a worth while cost to me. It is one of those pre-built sheds that you can order and have delivered, 34 by 20 feet. I put 2 inches of XPS foamboard insulation in the walls before I paneled over them, so there is a little insulation but not much. I'm sure that the doors and windows leak air too.

Fortunately I'm in rural Virginia, so the winters are fairly mild, but the summers are brutally hot.

My dust collector is the Oneida V3000, 3 HP, 2940 CFM, so like you say, I'm sure it is pulling a lot of air out of the shop. 'Cost of doing business' as they say. Consider too how much of that fine particle dust gets dumped back into the shop every time you go to empty the drum. Having all of that outside means that none of that dust ever goes back into the shop.

I do have one of those big box air cleaners mounted in the ceiling, and use it occasionally, but because it is so far from the source of the problem, I only run it if I'm doing a lot of power sanding or such. I also use that to run all night before I'm going to do a nice finish. Just to clean the air as much as possible.

Good luck with your new shop, I'm sure you will find many hours of peace there.

Log in or create an account to post a comment.

Sign up Log in