STL210: Turn on that lathe!

Turning experts Janet Collins and Josh Friend answer your turning questions in our very first episode dedicated solely to jamming sharp tools into spinning wood.This episode is brought to you by:

|

|

For more information on the American Association of Woodturners: http://www.woodturner.org

For more information on the 2020 Turning Symposium in Louisville, June 4-7, 2020: http://bit.ly/2wcI4Me

For more on Janet Collins: http://www.greenmountainwoodturning.com/

For more on Josh Friend: http://jfriendwoodworks.com/

|

7 Things I Learned While Doing Youth Turning Workshopsby Amy Costello |

Question 1:

From 9miletree:

I picked up a 1940’s Shopsmith a few months ago to use as a lathe. The turning tools that came with it are somewhat small compared to what I see turners using today. They also don’t seem to stay very sharp. I just got a new roughing gouge and it’s a world of difference.

1: Can you recommend some turning chisels for someone starting out in turning? Sizes and tool types? I’m considering updating either my parting tool or my skew chisel next.

2: How far should I be going with sharpening? I heard in a very old episode of Shoptalk Live, with Richard Raffan, that he only sharpens to some unthinkable grit, 60 or 80 comes to mind!

|

|

|

See it in Motion: Grind a Parting Tool |

Question 2:

From Andrew:

What are the reasons for having a dedicated scraper versus using a skew at a different angle? Do I really need to spend the money on a scraper?

|

|

|

Scrapers Refine Turned SurfacesSome experts say don’t use them, but scrapers clean up ridges left by gouges and greatly reduce sanding time |

Question 3:

From Jason:

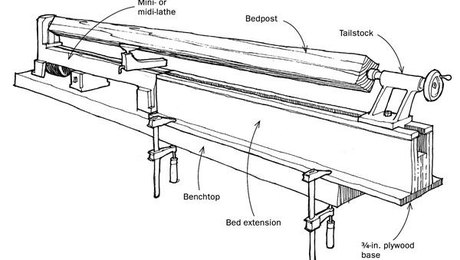

I’m making the base for Michael Robbins’s desk in issue #270 and am a novice wood turner. I was surprised to find that the rear stretcher length of 49 1⁄16” is too big for the biggest lathe I have access to. Furthermore, an online search didn’t turn up any lathes that will turn a spindle longer than 48 inches. I was able to make this work by arranging two lathes end-to-end (my makerspace multiple lathes). But how would you make this work using just one lathe? In short, how do you turn really long spindles?

|

Making a Sheraton Bed |

|

Bulk Up Your Benchtop Latheby Tim Manney |

|

Low-Cost Bed Extension for a Small Lathe |

|

Woodturning with a Steady Restwith Ernie Conover |

|

Basic Guide to Buying a LatheWhat to look for and what to avoid when purchasing a new or used machine |

Question 4:

From Mitch:

I spend all day in the shop wearing the hat of a double bass luthier. Scraps and off cuts from double basses are very large and I can usually make some fun stuff out of bass wastes such as bookmarks, butting boards, kid toys, pizza peels and recently a coffee scoop on my little lathe. I have a hefty machine room as well as a nice hand tool collection.

I have one of those small 10″ mini (micro) lathes. I use it daily for making tapered parts for basses. My question is: is there a hack for these small machines to be able to use gouges and other turning tools like you would with a larger lathe? I would like to expand my range of things I could make on the lathe, it’s addicting.

Every two weeks, a team of Fine Woodworking staffers answers questions from readers on Shop Talk Live, Fine Woodworking‘s biweekly podcast. Send your woodworking questions to [email protected] for consideration in the regular broadcast! Our continued existence relies upon listener support. So if you enjoy the show, be sure to leave us a five-star rating and maybe even a nice comment on our iTunes page.

Comments

“[Deleted]”

Nice change of pace!

My father once turned a mast for a small sailboat by mounting the tail stock on another piece of equipment across the room.

Log in or create an account to post a comment.

Sign up Log in