For a lot of people, the introduction to Fine Woodworking came sometime in the late 1970s or early 1980s, when they stumbled upon a fledgling issue of the magazine in their local library or bookstore. For them, already competent in at least the basics of the craft, discovering Fine Woodworking was like being handed a key to a room where all this new potential knowledge was locked away.

My path was different because I wasn’t even born when Fine Woodworking was first published, and despite my grandpa having a full basement workshop, and a full bookshelf of Fine Woodworking magazines, I was too young to appreciate either before he died. I was drawn to building things when I was a kid, but it was always with whatever scraps were lying around, a workbench that swayed back and forth like a pendulum, and a cheap tablesaw that, in hindsight, was just downright dangerous. I didn’t know I was woodworking; I was just making stuff. It took me a good 20 years to start channeling that desire to build things into projects that had a purpose beyond just creating for the sake of creating, and by then, Fine Woodworking was 170 issues deep.

And to make things worse, I dove in while working across the hall from the Fine Woodworking staff as an editorial intern at Fine Homebuilding. Picture me, fresh out of college, with a portfolio of past woodworking projects that included such dazzling accomplishments as a box made from 2 1/4-in. oak flooring that was cut with a dull handsaw and fastened together with an assortment of finish nails, many of which were bent over in the process. Along with my internship I then had access to a shop full of high end, industrial-grade power tools, operating in the shadow of some of the best woodworkers in the country. I quickly learned to use the shop at night when nobody was around, and hide my in-progress projects to avoid unwanted attention from the Fine Woodworking editors. Meanwhile, I read every Fine Woodworking article and book I could get my hands on, lurked in the shop asking questions and watching how the editors worked, the way they held a handplane, which clamps they used for what, and how they adjusted the tension on the bandsaw blade. I would hit roadblock after roadblock in my nighttime sessions, then go back home to my stash of books and magazines and find the answer in a past article. The whole experience felt like trying to assemble this great body of woodworking knowledge one little piece at a time. This was my education in woodworking, and my textbook was Fine Woodworking.

Fast forward another 15 years and what feels like 500 projects later, and I still feel like I’m learning every day that I’m in the shop. I also still treat Fine Woodworking as my textbook. Even if one of the articles in an issue doesn’t particularly interest me, I read the whole thing anyway. I’m always glad I did, and walk away with one or two new tricks, if not a whole different perspective.

For me, the articles that nudged me along on my journey included a wide variety of subjects, such as projects from heavy hitters like Christian Becksvoort and Mike Pekovich, technical content like testing glues and joinery methods, finishing know-how from Peter Gedrys, and discovering new ways to think about tool selection with the help of Chris Gochnour. The list goes on and on, and that’s what I love about Fine Woodworking; there’s always something to surprise me and add to my toolbox.

Editorial Director,

Fine Homebuilding and Green Building Advisor

|

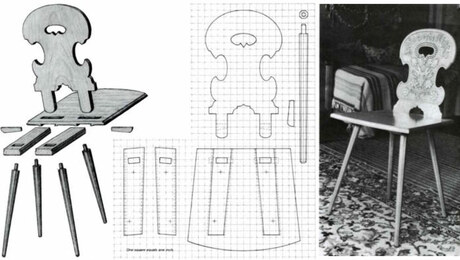

Build a Shaker Lap DeskCelebrate pen and ink with this quintessential case Christian Becksvoort |

|

Tool Test: WaterstonesThey’re the best choice for honing sharp edges Chris Gochnour |

|

Joinery ShootoutWe push 18 popular frame joints to the breaking point Douglas Moore, Thomas McKenna |

|

How Strong is Your Glue?We take six types to the breaking point, shattering some common wisdom in the process Mark Schofield |

|

Cherry Chest of DrawersDovetail joinery decorates this Shaker-inspired case piece. Michael Pekovich |

Log in or create an account to post a comment.

Sign up Log in