Choosing and mixing hot hide glue

Patrick Edwards discusses the different types of protein glues, why you should be using them, and how to mix hide glueThe traditional glue pot disappeared from wood shops and trade schools soon after World War I when synthetic adhesives took over, leaving later generations of woodworkers to learn this secret of the craft on their own. Animal-protein glues have many advantages over synthetics. They are very quick-setting; transparent to stains, oils, and other finishes; easy to clean up; and reversible, making repairs possible. They are also organic in nature, and are not toxic to humans or pets. If you doubt the strength of animal glue even with the host of antique furniture that has survived for hundreds of years, check out the test in FWW #192 (“How strong is your glue?”), where hide glue stood shoulder to shoulder with yellow glues and epoxies.

All wood glues create a mechanical bond by penetrating the porous surface and solidifying there. But animal glues also create a strong molecular bond with wood, due to the attraction between certain molecules and atoms. The glue sets initially by losing heat, and then cures fully by losing moisture. As mentioned earlier, this process is always reversible, and can be repeated even after a century or more.

The right animal glue for you

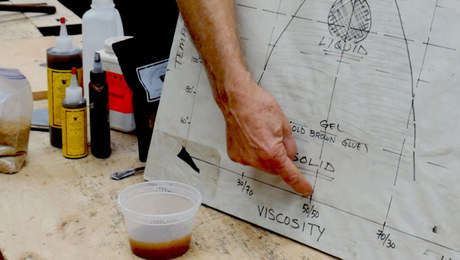

Although there are many excellent organic glues—from fish, milk protein, rabbit skin, horse bone and hide, and vegetable compounds—I’ll focus on hide glue, the most versatile type for furniture making. Today, hide glues are sold either in pearl or granulated form; I recommend only the latter, which turns to gel very quickly when cold water is added.

Hide glue can vary in quality, and it can go bad if exposed to moisture. Some people have sworn off hide glue after buying poorly made or poorly stored animal glue from indiscriminate sources all around the world, and then experiencing joint failures. Others complain about the smell. Good-quality glue has a very mild animal odor. If it smells rancid, it is bad and should be thrown out.

I recommend Milligan & Higgins 192-gram hide glue for all furniture-making tasks; I’ve been using it for 40 years. It actually is a mix of bone and hide glues, and has an open time of 1 or 2 minutes at normal room temperature and humidity levels, setting up as it cools. You can order hobbyist quantities of Milligan & Higgins 192 from Tools for Working Wood or from OldBrownGlue.com.

Comments

Excellent videos! I leaned a good deal of interesting technical and historical information. I also learned that I have used the hide glue that he makes, and it is a very good product.

In addition to the longer open time, one of the things I really like about hide glue is that it acts as a lubricant for putting together tight joints, like dovetails, box joints, and mortise and tenon joints.

Hide glue is a pleasure to use. Easy to apply, easy to clean up, and easy to remove if you get unwanted squeeze out. Not to mention that it won't mess up your finishes.

Great stuff!

I built the bulk of my English style primary work bench with hide glue (I ran out when ready to glue the top planks together, bummer). It's got a very large leg vise on it. It's taken a tremendous beating for years and doesn't show any signs of slowing down. The only time I use synthetic glue is when I know a piece is going to be used constantly in a damp or wet function, bathrooms or outside.

Here in UK (as far as I am aware), we can only get "pearl glue", and with no indication whether it is of bone or skin origin or its gram strength.

How do you rate this compared to your powdered 192g powdered glue?

I was taught that the water added to the glue should be distilled, as there are to many contaminants in tap water.

I'm no expert on this but I can't imagine 1000 years ago anyone thought of using distilled water for glue. I've seen many videos and article from people far more knowledgeable than I who never mentioned distilled water. Can't hurt, I suppose, but probably not necessary either. Just some thoughts.

Thanks Ben. Wonderful series by Patrick Edwards. Makes my unlimited membership worth it when I see videos such as these. The one thing I would have liked was a bit more of in the series was about gluing up traditional joints such as mortise and tennon, dovetails, etc. I know it was touched on and that the glues that have an added ingredient to help break up some of the hydrogen bonds have a slightly longer open time (or using warm water on the joint before glue up). As a beginner woodworker glue ups are stressful. Hearing a bit more about how much more open time we have and seeing a small box with dovetailed corners would be helpful. It's a minor issue. The veneer video in the series was awesome. Will need to think of a project to include some veneer.

Log in or create an account to post a comment.

Sign up Log in