STL212: The call of the patternmaker’s vise

Chairmaker David Douyard joins Mike and Ben in the studio, and they discuss using budget lumber, tools they covet, go-to chisels, and what one listener should do with his old patternmaker's vise.This episode is brought to you by:

and

|

Question 1:

From Sascha:

What are your thoughts on using cheap big-box-store pine for furniture (not even “select pine”). E.g. 6ft x 6 inch x ¾ inch boards for $6. I’m hesitant to blow $200 of lumber on something to learn, when I could do it with $30 worth of pine.

Question 2:

From Matt:

A question for the panel: What is one tool that you covet, but will likely never own, either due to price or practical considerations?

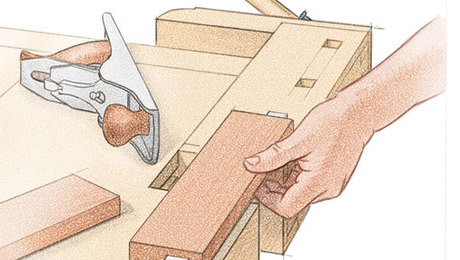

David–HNT Gordon Pattern Maker’s Vise

Mike – A Sauer and Steiner smoothing plane

Ben – A multirouter or pantorouter

Segment: All-Time Favorite Tool

Mike: Bridge City Chopstick Master

David: Lie-Nielsen Boggs Curved Spokeshave

Question 3:

From Mike:

I probably don’t need yet another woodworker’s bench, but the very first one I made 30 years ago isn’t quite up to par and I would like to replace it with a very stable bench, possibly a split top Roubo. Years ago I had acquired, very inexpensively, a vintage G.M. Yost patternmaker’s vise (similar to an Emmert), and it has been installed on this makeshift bench for many years. My question is, in your opinion, should I build the split top Roubo with a leg vise, deadman and wagon vise and move the Yost to a 2″ thick but only 30″ high solid ash assembly table I already have; or (b) incorporate the Yost into the new bench, instead of a leg vise?

I have to admit that the Yost vise is very substantial for run of the mill front vise use, but I really haven’t needed to rotate it, tilt it, or swivel the jaws very much, if ever. I primarily do rectilinear work, but I can see myself getting into projects involving more hand shaping, in which case the features of the Yost might be beneficial. Assuming that the 2” thick ash assembly bench can properly support the weight of the Yost vise, I would have just as much room to use it there as I will have on the new workbench.

|

Making Sense of Vises |

|

Patternmaker’s Vises |

Question 4:

From Ryan:

I don’t use chisels often but am working my way toward more hand working. I’ve heard over and over again how you need to feel what it’s like cutting with a sharp chisel to know if you are sharpening correctly. I have a number of my fathers and grandpas old Stanley and other brand chisels ranging from 1/4- 1” that haven’t been sharpened in years.

Should I buy 1 very nice chisel in order for me to understand what sharp really is? If so what size?

After listening to you guys it seems I will still have to sharpen the chisel once I get it but it will need much less sharpening than the 20 year old chisels I have.

Recommendations:

Ben – @masswoodworks on Instagram

Mike – @ddouyardchairmaker on Instagram

Every two weeks, a team of Fine Woodworking staffers answers questions from readers on Shop Talk Live, Fine Woodworking‘s biweekly podcast. Send your woodworking questions to [email protected] for consideration in the regular broadcast! Our continued existence relies upon listener support. So if you enjoy the show, be sure to leave us a five-star rating and maybe even a nice comment on our iTunes page.

Comments

Can we see a picture of Mike's chair?

I used a black and decker workmate as a shave horse. I collapse the two end legs and use the center vise to hold the wood. You sit at the high end and the down legs acts as a brake against your pulling. Works Great!!

Just when I thought that it was safe to return to STL, Ben says that INCA machines were made in Sweden!

Where is the ever erudite Dr. Kenney when we need him!

Log in or create an account to post a comment.

Sign up Log in