STL215: Steve Latta’s favorite vises

Contributing editor Steve Latta joins Mike and Ben to discuss when to peg a tenon, hammer veneering, broken bandsaw blades, CNCs, and what the difference is between a jointer and a planer.Question 1:

From Ken:

I have mounted an Eclipse 10-in. quick-release vise on my workbench and attached maple chops. The vise is machined purposely so the jaws are not parallel, presumably for holding power. Are the chops supposed to be beveled to compensate for this?

|

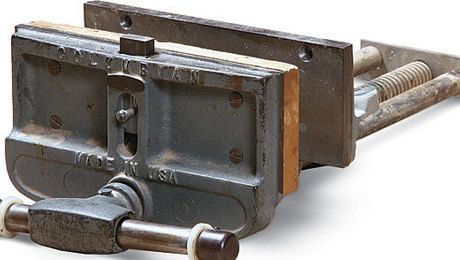

Restore a Vintage Vise |

|

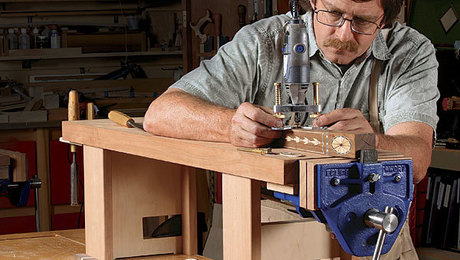

Mini Workbench Works Wonders |

Question 2:

From Chase:

When should you peg a tenon, and when not? I have an entry table I am making with square legs, mortise and tenoned into the aprons. There is certainly enough room for a 1/4″ dowel, but it would get a little awkward with two dowels trying to intersect each other inside the leg. Should I could drill the holes blind and short enough so the two pegs don’t intersect. Is this helpful, or am I just further weakening the leg?

|

Drawbored Tenons |

|

Segment: All-Time Favorite… whatever

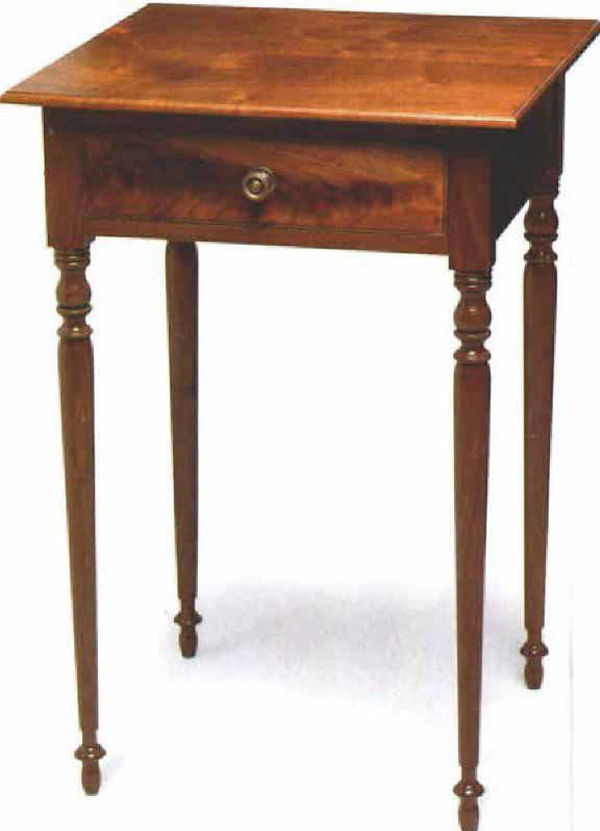

Mike – Technique Issue 148 – sidetable… shoulder to shoulder distance is everythign

|

Fast and Accurate Table JoineryA Sheraton-style table comes together easily, thanks to an efficient approach |

Steve – Technique: Hammer veneering Tool: Vacuum Press

|

Hammer veneering with hide glue |

|

A Vacuum Press Makes Veneering Easy |

Ben – Kiln drying his steam bends to get them to set overnight

Question 3:

From Larry:

The other day, I was making a straight cut with a 3/4″ wide blade on my 16-in. bandsaw. I had been cutting 1″ thick cherry and noticed that there were places where the feed rate was very quick and others places where it slowed considerably. I was pushing with the same force throughout the cut. I attributed this to variations in the density of the wood.

Then, switched to 1″ thick hard maple. Keeping the feed rate very slow the whole time. I took my time and didn’t force it. As I neared the end of the first cut, the blade started moving back and forth, not side to side, in the cut. I stopped pushing and reached for the switch, but before I could reach it the blade broke.

I checked the guides and thrust bearing to see if one of them had slipped, nothing had moved. The top guides were about 1″ above the board. Do you have any idea why the blade would move back and forth? I assume that it broke, and came off the front of the wheels, but why?

|

Essential Bandsaw Blades |

|

Safety Manual: Bandsaw |

Question 4:

From Josh:

I am a 21 year old burgeoning woodworker in California. I am currently building a desk organizer for my girlfriend who is about to graduate college and attend law school. The only problem I have encountered thus far is regarding the center “tray.” I have a piece of 6/4 English Walnut that I acquired from a local milling shop, and need to add a draft angle so that one edge is 1/2 inch in thickness and the rear measures 1-1/4 in. I had thought of building a sled of sorts to add the angle, then run the whole apparatus through the planer, but feel that might be slightly dangerous. The dimensions of the stock are 1.5x8x13, and the pockets will be milled after the angle is added using my small, desktop CNC machine. How would you guys approach this problem? Hand tools? Buy a bigger band saw? I am excited to hear your input, and thank you for providing such an informative, entertaining and exciting way to approach this wonderful hobby.

Question 5:

From Bob:

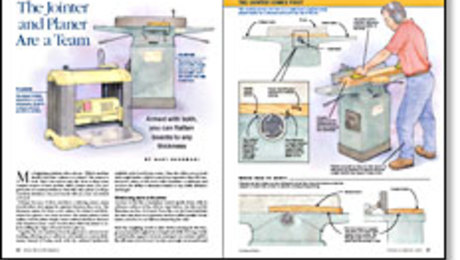

I just watched Mike’s video on milling lumber, and it made wonder about milling machines. If I had a jointer and planer, I might know the answer to this question. If a jointer makes lumber flat and square, why couldn’t you do all the flattening on a jointer. Is there something about a planer that flattens better?

|

Advanced Milling Techniqueswith Michael Pekovich |

|

The Jointer and Planer Are a Team |

Every two weeks, a team of Fine Woodworking staffers answers questions from readers on Shop Talk Live, Fine Woodworking‘s biweekly podcast. Send your woodworking questions to [email protected] for consideration in the regular broadcast! Our continued existence relies upon listener support. So if you enjoy the show, be sure to leave us a five-star rating and maybe even a nice comment on our iTunes page.

Comments

I have my own to manage, I can't be worrying about Steves favorites! ( I know a dozen other viewers were thinking the same when they read the heading...)

You know I love a play on words!

Log in or create an account to post a comment.

Sign up Log in