Simple Setup Hones Planer and Jointer Knives

With this jig and a set of sharpening stones, you can rehone even the "disposable" jointer and planer blades in your shop.

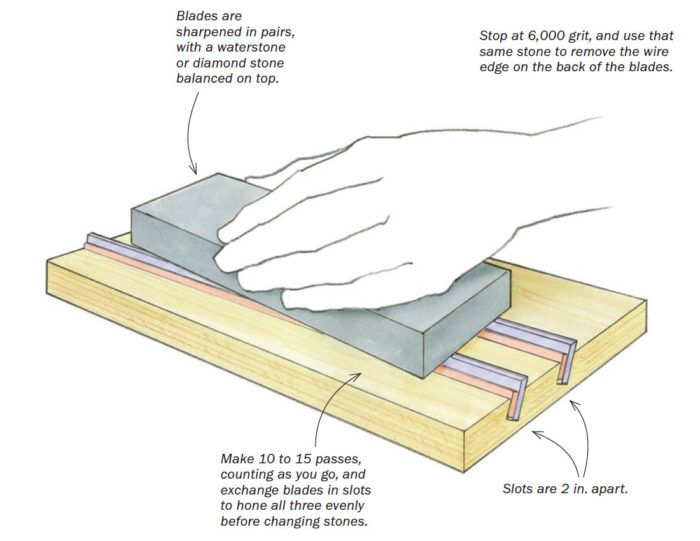

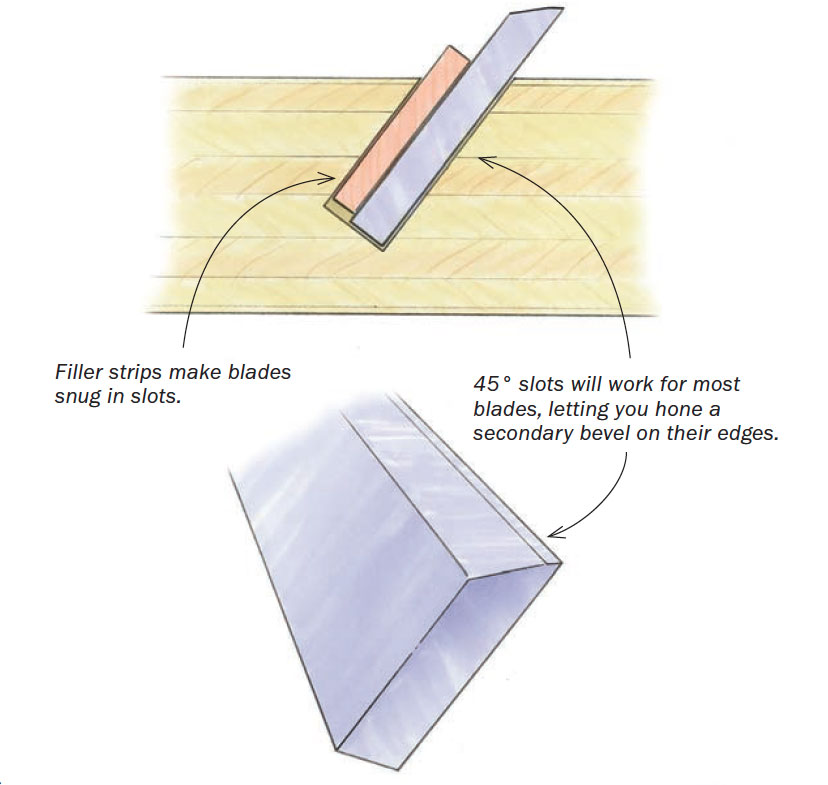

Tearout can get nasty when jointer and planer blades get dull. Disposable blades are expensive to replace, and sending out standard blades for resharpening puts your woodworking on hold. But with this simple jig and a typical set of sharpening stones, planer and jointer blades can be quickly rehoned in your shop. It’s just a scrap of 3/4-in.-thick plywood with two angled slots cut on the tablesaw, roughly 5/8 in. deep. To make the blades fit snugly in the slots, I rip thin filler strips.

For the “disposable” blades that go in my DeWalt 735 planer, which are roughly 1/16 in. thick, I cut the 45° slots in a single pass with my 1/8-in.-thick combination blade, and make 1/16-in. filler strips. For thicker blades, the slots and strips would be different. The angles might be different also, since the goal is to hone a secondary bevel on each blade, not the entire main bevel.

The first step is numbering the planer blades to keep track of them. To be sure I hone an equal amount from all three blades while sharpening them in pairs, I swap out the blades, honing each one twice with each successive stone. I use waterstones, but diamond stones would also work.

Starting with the 1,500-grit stone, I make 10 to 15 passes over the first two blades, holding the stone at an angle to the blades as I slide it end to end. I switch out the blades until each one has had two series of passes with that first stone. Then I do the same with my 4,000- and 6,000-grit stones, dipping the stones in water each time I reload a blade. Last, I lay the blades flat on the finest stone to remove the wire edge on the back.

Disposable blades come with the secondary bevel already established, and you can re-hone it a number of times before it’s is too wide for efficient honing and the blades need to be discarded. If your planer or jointer knives are the thicker, permanent type, however, you can hone them as much as you like before sending them out for professional sharpening to regrind the entire bevel.

—JOHN DIVITTORIO, Vancouver, Wash.

Illustrations by Dan Thornton

From Fine Woodworking issue #282

Fine Woodworking Recommended Products

Makita LS1219L Miter Saw

Stanley Powerlock 16-ft. tape measure

Ridgid R4331 Planer

Comments

Great tip, thanks. I am thinking of quite a few tools I could sharpen in a jig like this.

Great tip...just tried it and it worked great. Saved me from buying a set of replacement blades. That means I get to spend that money on another tool...right...

Very clever. I am wondering why you don't put your slots 1" apart, so that you can put all 3 blades into your block and sharpen them all at once.

Log in or create an account to post a comment.

Sign up Log in