STL216: Accessorizing your new table saw

Mike, Anissa, and Ben discuss tablesaw accessories, shop rituals, testing sharpness, knockdown fasteners, and tall people.Question 1:

From Jeff:

I’ve always been a creature of habit and routine. Some have routines to start their day, warm up at the gym, or to prepare for bed. Am I weird for having a warm up routine in the shop? I’ll usually start with a small clean and organization of anything that’s out of place, then maybe read an article or watch a youtube video about woodworking or tools, then I’ll sometimes even make a few cuts on scrap using either hand or power tools then being work on the task of the day. Am I crazy or do you find some validity in this practice? Does anyone there have a shop warm up?

Share your shop routines below in the comments!

Question 2:

From Matt:

I’ve managed to get by without a table saw for a number of years, but now, I am considering one. I was wondering what additional equipment I need to budget for that you would consider essential. Eg. Outfeed table, miter gauge, crosscut sled, dado stack, blades, zero clearance inserts, push pads, feather boards, etc. It seems there are endless accessories that one could buy. Which are your favorites?

|

|

|

Build a Basic Tablesaw Outfeed Table |

|

Outfeed Table Doubles as a Workbenchby Kelly Dunton |

|

|

|

|

|

Segment: All-Time Favorite Tool

Mike – Delta tenoning jig

Ben – Richeson 899 Palette knife with sandpaper stuck to it

Anissa – Cork backed ruler

|

|

Question 3:

From (a different) Matt:

What is your preferred method of testing edge sharpness? Summer is coming and I don’t want to walk around with shaven arms.

Question 4:

From Brad:

Is there a jig to make the Ikea style joint for furniture you want to assemble and disassemble? Is there another type of joint that you would recommend for this application of furniture you want to be sturdy but also be able to take apart to move, either for shipping or for ease of transport?

I love the podcast, and I’ve listened to every episode. Ben, has anyone told you that you sound just like Chef David Chang? I listen to his podcast too and the similarities are crazy. >

|

Threaded Inserts |

Question 5:

From (a different) Jeff:

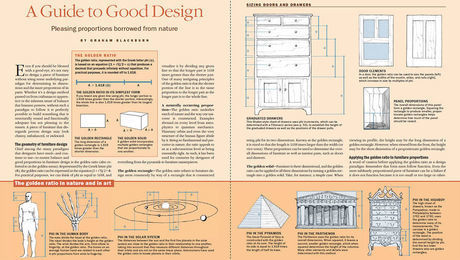

My entire family is tall. I’m 6’7, my wife is 6’3 and my adult daughter is 6’6. I expect an answer or we’re going to come and pay you a visit… just kidding. What thoughts do you have with respect to modifying proportions that basically put furniture such as dressers, chests (pieces that typically have drawers near the floor ) at a more practical height. I’m looking for ideas of how to eliminate the low drawers without the piece looking like Frankenstein. I’m looking to start working on furniture for my daughters place, likely leaning toward Mike Pecovich’s aesthetic.

|

Stylish Details Enliven a Low Dresser |

|

A Guide to Good DesignPleasing proportions borrowed from nature |

Recommendations:

Ben: twoodfd on YouTube

Mike: Rolling Thunder Revue: A Bob Dylan Story by Martin Scorsese

Anissa: Win the Wilderness on Netflix

Jeff: Alone in the Wilderness

Every two weeks, a team of Fine Woodworking staffers answers questions from readers on Shop Talk Live, Fine Woodworking‘s biweekly podcast. Send your woodworking questions to [email protected] for consideration in the regular broadcast! Our continued existence relies upon listener support. So if you enjoy the show, be sure to leave us a five-star rating and maybe even a nice comment on our iTunes page.

Comments

I like the routines... My shop days are usually weekends. I have a rule of no power tools before 0900 or after 1700 to be nice to my neighbors. If I hit the shop by 0800 I have time to get in the right head space. My first aid box is on the wall by the garage door so it's there when I walk in and walk out. It has a little bowl on top of it and the first thing I do is take off my wedding ring. The first aid box is a good reminder of consequences of not doing that. It also has my safety glasses (with readers in different strengths) and I grab the +1.5 ones. I read a version of the Woodworkers Prayer I got long ago. I set my music up then do a good sweep and straighten my side bench. Next I set up my mobile workbench and mobile table saw and give the saw a good cleaning with Boeshield, check the blade is square, and hook up dust collection. If I'm going to be doing hand work, I'll make sure chisels and planes are sharp or give them a quick sharpen. By then, it's usually 0900 and I can get to work following the list I left on the whiteboard the last time. At the end of the day, I note on my whiteboard where I left off then I do most of the startup in reverse.

The Woodworkers Prayer

Oh Lord, so far today I’ve not hurt myself nor anyone else. I’ve not coveted my neighbor’s tools, and I’ve not damaged any of mine. I’ve not been led into temptation to buy one of those fancy laser-guided saws that Norm uses on The New Yankee Workshop. I’ve not messed up any of my projects, nor had any cause to take Thy name in vain.

For this I give thanks. But, Lord, I’m gonna get out of bed pretty soon, and then I’ll need all the help you can offer…

I've been admiring the cabinet behind Mike since you've been doing the podcast from home. It looks similar to a cabinet that my grand parents had right down to the color and the worn paint. I'd love to be able to find that cabinet. Or is a smooth move from Mike trying a new finishing technique?

Maybe you should add a standard feature for Shop Talk Live called “Let me google that for you” or something like that. Usually that phrase is used in a condescending way but in this case it’s just just a simple helping hand. Sometimes when you don’t know the right lingo it’s feels almost impossible to find what you’re looking for whether it’s at the hardware store or google. For today the phrase would be “furniture knock down hardware”. Once you know that magic phrase then a world of information opens up to you that is way beyond what anyone will recall off the top of their head.

Tall people are asked to reach the top shelf, is it okay to ask short people to bend over to reach bottom drawers?

I have a small shop, and hesitated to make an outfeed table, because of the space it would take. Also, my shop floor isn't perfectly level, and every time I'd shift the saw (it has bear crawl casters), I'd have to re-level the OF table.

Then I found a design in a Woodworker's Journal article (Feb 2009, Chris Marshall). I actually subscribed just to gain access to the archived article.

It's perfect. Mounted on the back fence rail, and supported with a single leg that angles down to the bottom of the TS cabinet itself. So, nothing touches the floor, no leveling required. Ever. (Well, just the one time...) Better yet, it's on a hinge (wood & lag screws). The leg is folding/extending, and the top folds down and just hangs from the back of the saw if you don't need it.

I thought I'd be folding it up and down frequently. Uh, no. I've left it in the open position for a year now. It's like working on the deck of an aircraft carrier.

Moosie57 - That's great to hear. I've been surveying outfeed table designs, mine is on wheels and I need to move it occasionally, and Chris's design caught my eye. It's elegant, provides plenty of space and folds out of the way when needed. Shopnotes has a similar design and shares many of the same

elements. My apologies to the FWW staff for promoting a competitors design. The only folding table I found on this site was in FWW #163 and it's nowhere near as elegant as the others I've referenced.

If my saw was stationary, one of the many good designs in FWW would certainly fit the bill.

Not sure if you look at comments from older shops but here goes.

I Hana a rigid magnetic feather board that I use every time I have a board narrow enough to use it. Greatest invention since the rip fence. It seems to be a orange version of a mag switch feather board.

Best stick on sand paper. Is from bush products. I’ve only found it at the nj woodworking show. Btw. The bush oil he sells is amazing. Take the sandpaper off your pallets knife with a card scraper and goof off.

Log in or create an account to post a comment.

Sign up Log in