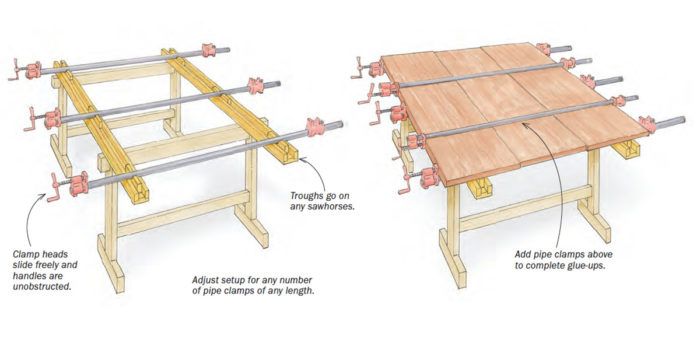

Workshop Tip: Pipe-clamp station adjusts for most glue-ups and stows easily

Sliding clamp supports solves problem of awkward pipe clamps

When I set pipe clamps on my workbench or assembly table, the handles run into the benchtop, the clamps tip over sideways, and it’s hard to slide the heads with workpieces weighing the pipes down. These sliding clamp supports solve all those problems, creating an adjustable glue-up station that stows easily on a shelf.

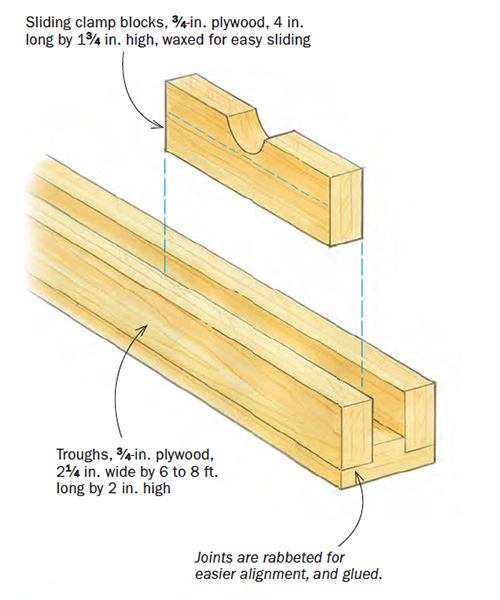

Made from plywood, with joints rabbeted for alignment and glued together, the long troughs hold simple sliding blocks that cradle the clamp pipes. Sit them atop sawhorses, and the troughs and the sliding blocks are adjustable in every direction. You can use long or short pipe clamps, in any array, for panels, frames, and other common assemblies. The clamp heads slide freely and the handles are unobstructed. When I’m done, I stow the supports on a high shelf and slide the sawhorses out of the way.

I made my troughs 8 ft. long for the largest tabletops I produce, but 6-ft. troughs would be easier to stow and handle. To make the sliding cradle blocks, start with larger squares, use a Forstner bit to drill a hole a little larger than the pipe diameter, and then saw the squares in half. I waxed the blocks so they slide easily, and recently tacked covers on the ends of the troughs so the blocks don’t slide out when I stow them.

Click here to enlarge illustration above.

—EBEN LOVEJOY, Oakland, Maine

Illustrations by Dan Thornton

From Fine Woodworking issue #284

|

|

|

|

|

Fine Woodworking Recommended Products

Bessey K-Body Parallel-Jaw Clamp

Glue Bottle

Titebond I

Comments

A pair of level, equal hight saw horses, this setup and "Boom!", your work bench is once again free to do work on. I can see that four cleats made out of 1 x or 2 x material attached crossways under each trough to hold them in snug alignment with the saw horses would add to their stability and help keep the "Oopsie's" at bay.

Log in or create an account to post a comment.

Sign up Log in