STL224: Is there one true way to sharpen a scraper?

Mike and Barry discuss milk paint, scraper sharpening, shellac finishes, when to sharpen a tablesaw blade, and their smooth moves.This episode is sponsored by Pony/Jorgensen and Titebond

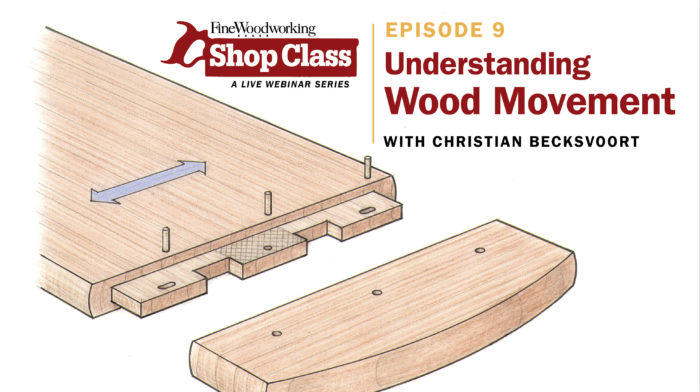

Webinar: Understanding Wood Movement with Christian Becksvoort

Sign up for the Fine Woodworking weekly eLetter

Sign up for a Fine Woodworking Unlimited membership

Question 1:

From Nathan:

I am building my daughter a toy chest out of pine, (preparing for a Windsor chair build when I’m on the east coast), and I would like to practice with milk paint. What tips do you have for someone just getting into this finishing technique?

P.S. Ignore everyone that says the podcast is to much fun. That’s most definitely needed. Whenever I’m driving to work, 30-45 minutes a day, I’m either listening to this or the mortise and tenon podcast. People seem to get to worked up about woodworking and forget that it’s supposed to be an enjoyable endeavor.

|

|

|

Rediscovering Milk PaintGet a rich, traditional look or break out of the bag for a wide range of effects |

|

An Antique Painted Finishby Dan Faia |

|

A stunning black-over-red milk paint finishElia Bizzarri shows how to layer black milk paint over red to create a rich, layered look on his Windsor chairs. |

Question 2:

From Bob:

I’ve seen numerous articles and been taught by a couple of experts on the skill of sharpening a card scraper. Some methods are as complex as fine tuning a hand plane and take about as long. Some are relatively simple, but not quite as simple as a method someone demonstrated at the last woodworking show I attended. The craftsman did most of his work while seated at a shaving horse. He said he used card scrapers a lot and then proceeded to show how he sharpens them. His method is to simply clamp the scraper vertically so the edge is facing him, then run a large metal file across the edge. I tried it and it does create a burr on both sides of the scraper after a few swipes with the file. The scraper works fine, pulling shavings better than any other method I’ve ever used.

So is this shortcut a good method or am I ruining my scraper in the process?

|

|

|

Tune Up a Card Scraperby Brian Boggs |

|

Question 3:

From Joe:

Shellac is my favorite go to finish and I use it on most projects. In a per-Covid 19 lock down, I would usually put 4 or 5 coats of a 1.5 to 2 pound cut on and call it done. Now that I am working from home, I have been able to go out to the shop and put a coat on in about 5 minutes and repeat often over a few days. As such, I’ve been putting on closer to 10 coats. Is there such a thing as too many coats of shellac? It looks good and feels good after waxing. I just wonder if it will do something funny 5 or 10 years down the road. Any thoughts or insight would be appreciated. Many thanks.

PS After the first 3 coats of shellac I sand with 400 grit lightly to remove the nibs before continuing.

|

Make Shellac Your Go-To Finishby Mario Rodriguez |

|

Smooth Moves:

Barry – Not checking the fit of a dovetail frequently enough and shooting waaay past it.

|

Better Way to Attach Tabletopsby Andrew Hunter |

|

Lighter, Stronger Frame-and-Panelsby Andrew Hunter |

Mike – Not trying to mortise to boards at once a long, long time ago.

|

How to Sharpen Hollow-Chisel Mortising Bitsby Bob Van Dyke |

|

Sharpen a Mortiser Bitby Roland Johnson |

Question 4:

From Jack:

How do you tell a woodworking friend that their design/plan for a project is I’ll advised. Recently, a friend has been planning to build a tool chest. In our woodworking chat group, we discuss plans and builds (and shop talk Live) almost daily. The subject of wall thickness on the chest and attaching hinges came up. The usual lively debate started, with plenty of sucking through teeth and chin stroking. The stubborn arguments ensued, with everyone thinking they are right. So question is, how do you productively tell someone they are wrong?

Just a fun question, all our disagreements in the chat are always for the fun of it and meant in a good natured way.

Love the podcast, Love from your UK based Shop Talk Live fans.

Question 5:

From Charles:

How close do you get your chip breaker to the cutting edge of your plane blades? Do you worry about the pressure from the chip breaker bending or deforming the thin cutting edge?

Question 6:

From Chase:

I have been at this for about four years. Thus far, I have used the $45 blades from the big box stores. I use them until they get dull, sit them aside and buy another. Is there a significant difference in quality when jumping up to expensive blades (Forrest)? Or would I be better suited resharpening a mass quantity of cheaper blades. FYI Kerf size is not a huge factor as I have a 3HP saw. Thanks for any advice!

|

Sharpening Services UpdatedFormer Fine Woodworking Associate Editor Tom Begnal wrote a great article in 2007 about sharpening services and their prices. In it, Tom notes the importance of a sharp edge, and… |

Every two weeks, a team of Fine Woodworking staffers answers questions from readers on Shop Talk Live, Fine Woodworking‘s biweekly podcast. Send your woodworking questions to shoptalk@taunton.com for consideration in the regular broadcast! Our continued existence relies upon listener support. So if you enjoy the show, be sure to leave us a five-star rating and maybe even a nice comment on our iTunes page.

Comments

Colour coordinated with the T-Shirts.

Log in or create an account to post a comment.

Sign up Log in