Use an inner tube to clamp weird glue-ups

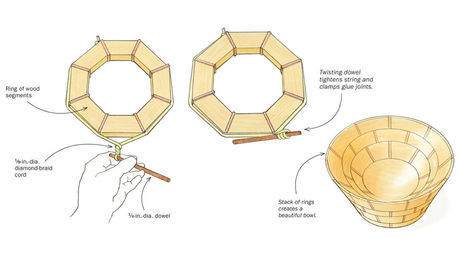

In issue #285, Clark Kellogg assembles the sides of his hexagon boxes with some innovative clamps from an unlikely source: a bike shop.In the Nov./Dec. 2020 issue of Fine Woodworking, Clark Kellogg makes a beautiful hexagonal box. It’s fairly difficult to clamp up, so Clark uses a bicycle inner tube to add clamping pressure. For demonstration purposes, I decided to use the finest MDF I had on hand to make an octagonal box. I started by ripping out eight staves, with 22.5° bevels on each side.

On an octagon box–with eight sides–there are 16 bevels. So if each one is even half a degree off, the resultant error would be 8°. I halfheartedly tried to dial in my tablesaw blade as close as I could, but I believe I was probably closer to 22.6 degrees than I was to 22.5. For this demonstration, I called it close enough and decided to glue up the staves in two halves.

After laying all of the pieces on my bench, I taped the joints together as tightly as I could. I applied glue to all of the joints except the outside pieces and the joint in the very middle. You might be able to get away with just using the blue tape to pull the pieces together tightly enough, but Clark’s use of an inner tube blew my mind when I first saw his article. After being grateful I don’t throw away incredibly useful things like old inner tubes, I dug out a blown tube from my son’s BMX bike, sliced it relatively in half, and used two clamps to hold it in place before and after wrapping it tightly around the octagon box. I was very impressed with how much pressure the inner tube applied to the box.

After the initial glue-up was dry, I sanded each side flat and then glued up the two halves.

Another option would be to use some absurdly long rubber bands that I bought from a luthiery supplier, Stew Mac. They’re meant to be used to clamp binding around the top of guitars. I normally use them for clamping fretboards onto ukulele necks. The nice thing about the rubber bands is that you can just wrap them around the box and tuck the ends under–no clamps needed. Like the inner tube, it’s surprising how much clamping power you can exert on a piece with them.

So next time you clamp up something odd, find an old inner tube. Mike Farrington says that he goes to bike repair shops and they throw out inner tubes all the time, so they give them to him. I’m going to try that because I’m certain I need more inner tubes in my stash now.

|

|

|

|

|

Comments

Yo Ben, Back in the '80's FW did an article using an inner tube wrapped around 1/8" laminates for radical bends and twists. That article recommended using formaldehyde glue for slow setting. Might not want to go there but I had a lot of fun with it.

Enjoyed it. Keep 'em coming Ben.

Ben rocks, as always.

This video was short, simple, and juuuuust fun enough to make me wanna cut some weird angles and glue something together!

I have some old bike inner tubes and all I've use them for thus far is to provide clamp cheeks. Glue 'em on the face of sash and bar clamps to avoid marring the work and they don't fall off like wooden cheeks.

I will certainly bear that in mind in future to use them to actually clamp things themselves.

Nice tip. I'm wondering how Clark Kellogg (or yourself) cleans up the glue squeeze out on the inside of a smallish box.

For clamping tasks like this and reverse turning on the lathe I use that plastic stretch wrap available in packing departments at big box stores. It's disposable and inexpensive and comes on it's own dispenser. It is also very strong and gets stronger with more wraps.

Log in or create an account to post a comment.

Sign up Log in