STL226: Buying a used drill press with Rollie Johnson

Rollie Johnson joins Mike and Ben to discuss handplane restoration, 110v vs 220v for machines, planer snipe, and everything you should know before buying a drill press.Question 1:

From Dave:

I recall editors on the podcast remarking that drill presses are good candidates for buying used: What essential specs should we be limiting our search around? Are their lemons we should be sure to avoid? What common points of failure exist, and how do we inspect a used drill press? (I imagine this could be a good Rollie Johnson article).

|

|

|

|

|

Question 2:

From Andrew:

My table saw can be wired for 110 or 220. Right now I have it on 110. I have space in my breaker box for a 220 breaker and I can add one at no cost. Would it be worth the effort to up my saw to 220? I really don’t have problems with it stalling and it seems to have ample power. Is there a real benefit that I will notice? It’s a Grizzly 10” contractor saw.

And another about 220v 110L:

From Matt:

I have three pieces of equipment set up for 240V in my shop but I only have one 240V plug. I’m getting tired of plugging in and unplugging extension cords. The lathe and the band saw, can be rewired for 120V and there’s a 20A plug right beside each of them. Is there any advantage one way or the other? Will I be giving up some power, efficiency, or durability of the equipment if I rewire them to 120V?

|

Segment: All-Time Favorite

Mike – Steam bending

Ben – Long feeler gauges

Rollie –

|

|

|

Question 3:

From Chase:

I recently attempted to restore two Bailey planes I found at an estate sale. While using electrolysis to remove some rust, I crossed the cables in reverse which caused all of the rust to accumulate ON the planes. When I rectified the error, all of the rust being removed from the planes caused severe (if you’re cringing inside, imagine how I feel).

Is the pitting going to affect the usability of the tools, or is this strictly a cosmetic defect? I am most concerned about the areas around the mouth, etc… I do have plenty of other planes to use, and I don’t want to sink a bunch of time into these if it is futile.

|

|

|

|

|

Question 4:

From Robert:

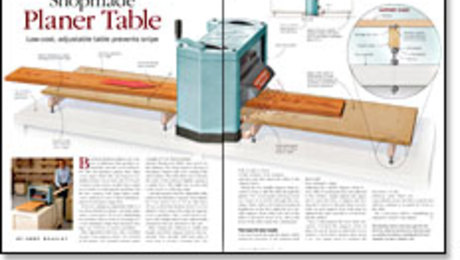

I’ve been wondering why planer manufacturers don’t provide two infeed and two outfeed rollers to help eliminate snipe. With two points of contact from overhead, it would theoretically keep the stock flat to the table regardless of where the stock is in the process. I would also assume that this arrangement would be coupled with a rigid one-piece table with sufficient length on either side of the rollers, not counting any extension wings.

For benchtop planers, I suppose this would make the tool larger, and maybe the dual rollers would have to have some distance apart to overcome any lifting force of the cutter head.

|

How to Avoid Planer Snipe on Short StockLearn how to avoid snipe when planing short stock by lengthening your wood. |

|

Every two weeks, a team of Fine Woodworking staffers answers questions from readers on Shop Talk Live, Fine Woodworking‘s biweekly podcast. Send your woodworking questions to [email protected] for consideration in the regular broadcast! Our continued existence relies upon listener support. So if you enjoy the show, be sure to leave us a five-star rating and maybe even a nice comment on our iTunes page.

Comments

Hey guys great show. I am a master electrician and thought I could simplify the explanation Rollie gave in regards to multi voltage 120/240v motors. In these systems the input wattage ( power consumption) will remain the same. Voltage and current are inversely proportional to one another. Wattage= voltage x current or p=E x I. Simplistically put ( not factoring for system efficiency) if your wattage is equal to 120w and your voltage is 120v than your current draw will be 1 amp. If you increase your voltage to 240v ( residential rms voltage between each leg is in fact 240 not 220) your current will be .5 amps. The main benefit to wiring a system at 240 volts is that the heat created by the operation of the motor will be greatly reduced thus allowing for a longer life cycle. Another benefit is to allow for the installation of smaller gauge branch circuit wire which reduces the cost.

I hear a lot of people ask this question and this explanation typically helps. Thanks for the great podcast

Mike

Next time you need to steam bend a piece a quarter inch/foot call me, most of the wood in my stockpile is bowed at least that much.

Dock 16

Great episode. Ben, timestamps for each question or segment would be a great upgrade for STL.

Log in or create an account to post a comment.

Sign up Log in