STL231: Fancy router tables vs. plywood with a hole in it

Mike and Ben discuss oddball panel glue-up theories, the need for a fancy router table, smooth moves, and Mike's upcoming book.Question 1:

From Paul:

Let’s say one is making a wider panel or tabletop from solid stock so that a glue-up is required to obtain the necessary width.

When preparing the stock, I know there are valid reasons for ripping the boards into narrower strips. The board might be wider than your jointer, or your stock might be cupped enough that you will end up too thin if you try to remove all the cup at once. Sometimes you see it said that by ripping the stock and flipping every other board over before gluing you will end up with a panel that stays flatter. I don’t like to do it that way because it makes hand planing a pain, but I understand the idea.

But I have also heard it argued that ripping the boards into narrower strips and then gluing them back together in the exact same orientation–no flipping or rearranging–also results in a more stable panel. I don’t think I buy this. I think if you rip a board in half and then glue it back together exactly as it was, that it will still move the same way and amount that it would have if you hadn’t ripped it. But that’s just my opinion and I’d like to hear from the experts!

Thanks for any light you can shed on this. Love the pod and the mag enough to be an unlimited member!

PS: Yes, I’m an engineer

|

I can’t find the Instagram post we talked about. I’ll keep looking -Ben

Question 2:

From Kevin:

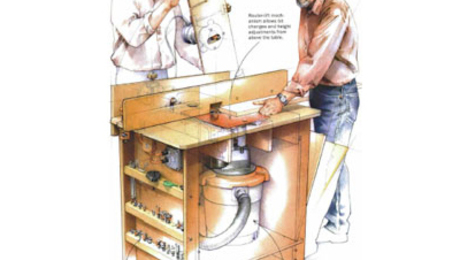

Over the last couple of years I’ve been fitting up a 20×24 shop and pretty much have most things I need, but I’ve been on the fence about adding a router table. My space is about the size of Mike’s, and though I’ve got room for a router table, everything is a spatial and tool compromise at this point. For example in the space I’d be putting the table in, could alternatively add more lumber storage or a spindle/disc sander, or a small CNC machine.

I’m curious how others on the show feel about having a dedicated router table and how often they get used.

|

|

|

|

|

|

|

|

Segment: All-Time Favorite

Ben – Cutting a finish bubble off with a brand-spankin’ new razor blade

|

Mike – Taping pieces together to run complimentary dadoes on the tablesaw

|

Question 3:

Two quick wood questions.

From Charles:

What do you folks think of hickory for a glued up slab 2”x 18”x73” with a 3 ¾-in. wraparound of Ash.I Iive now in North Carolina, used to live in CT, and I am a 74 year old apprentice and will never stop learning.

From David:

I was given several “walnut” slabs that I suspect are actually butternut due to the light color and distinctive walnut grain pattern. I planned to use this generous donation to build a shaker style workbench, in the spring. If it’s butternut, would you still use it to build a workbench?

Recommendations:

If you have the means, get a 3d printer.

Every two weeks, a team of Fine Woodworking staffers answers questions from readers on Shop Talk Live, Fine Woodworking‘s biweekly podcast. Send your woodworking questions to [email protected] for consideration in the regular broadcast! Our continued existence relies upon listener support. So if you enjoy the show, be sure to leave us a five-star rating and maybe even a nice comment on our iTunes page.

Comments

By ripping the board and re-glueing it you have severed the grain, you have created two totally separate boards, they are no longer brothers and will act on there own.

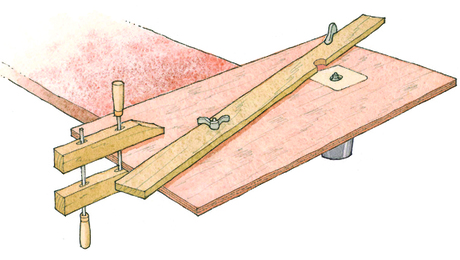

I made a jig about 3 feet long for cutting a large circle with my router. It turns out to be great for routing a rabbet in the back of a cabinet that is already assembled. The jig actually straddled the width of the back, making a very steady support.

Catching up on old episodes. Wish I had watched earlier so I could second the recommendation for a 3D printer. There is a bit of a learning curve, but the ability to make custom DC fittings alone could be worth it. Router pattern templates are just icing on the cake. Make friends with a printer owner if nothing else.

Log in or create an account to post a comment.

Sign up Log in