From the bench: Resilience runs in the family

Tony O'Malley's thoughts turn to retirement, role models, and how he learned to deal with life's setbacks through the example of his grandfather.

Synopsis: Tony O’Malley’s thoughts turn to retirement, role models, and how he learned to deal with life’s setbacks through the example of his grandfather.

I’ve been thinking about retirement lately, though my wife has other thoughts on the matter. In addition to wondering how much longer I want to keep making custom cabinets and furniture as a full-time business, I sometimes ruminate on how I ended up as a woodworker in the first place, starting 35-plus years ago. Like many, my story involved a turn from another line of work. Few of us follow our fathers (let alone our mothers) into this trade. And anyway, since I grew up without a father in the house, I’ve had to look for other influences.

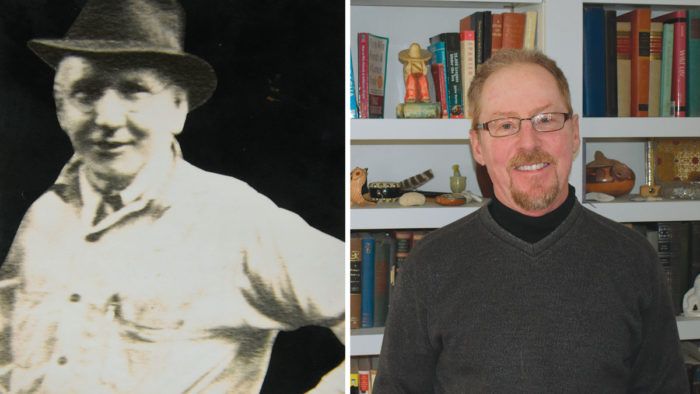

My mother’s father, though I never met him, was one strong candidate. I was named after him. As the stories go, Anthony Farrell lost his right arm in some kind of big machine at the Budd Locomotive Company in Philadelphia around 1928. A curious silver lining to the tragedy was that the company kept him employed all through the Depression that followed soon after. (This was before the advent of workers’ compensation programs.) He reportedly adjusted well, doing all manner of tasks around the plant and was, literally, a one-armed paperhanger and carpenter in his spare time. I’ll come back to grand-pop Farrell (shown above) in a minute. By the way, I became a grand-pop myself a few years ago, and now have two grandchildren.

My career path took its sharp turn shortly after I graduated from college. I worked for a couple of years in hospital administration, and hated the pressure and suit-wearing aspects. I had dabbled a little in self-taught woodworking during college. My growing interest was amplified by the burgeoning of custom furniture work in Philadelphia at the time, the fruits of which were offered every year to the public at The Philadelphia Furniture Show, starting in the mid 1990s. That was also when I found and subscribed to Fine Woodworking and caught the woodworking bug. But how and why was the fever strong enough to lead me to quit a decent-paying, career-track job for a minimum wage position ($4.25 an hour!) in a line of work where I had no experience? Having a supportive spouse was a key factor.

Not long into my first year working full-time in a woodworking shop, I had a serious accident on a big old tablesaw with a 16-in. blade. I had minimal training, the saw lacked any kind of safety guard, and I did something really stupid—a terrible combination of ingredients! The blade badly cut a couple of fingers on my left hand and completely severed my pinky. Fortunately, an intrepid co-worker was able to retrieve the digit from the sawdust and bring it to the hospital. Also luckily, this was during the advent of microsurgery, and my finger was successfully re-attached, though a good bit shorter. (There went my fall-back career as a guitarist!)

When I went back to work, I was terrified to use that same tablesaw. Maybe that’s when I channeled my one-armed grandfather. I felt somehow initiated into a select club, one of highly dubious distinction, that compelled me to stay the course and prove my mettle. Over the next five years at that shop I learned a lot—about furniture making, residential cabinetry and its installation, as well as commercial millwork. I learned how to fix mistakes, and avoid them in the future. This wide range of exposure helped me stay employed over the years, self-employed for the last 20 years. Early in my self-employment I even exhibited at the Philadelphia Furniture Show, where I learned the harsh truth that selling custom furniture is an exceedingly hard way to earn a living. That’s partly how I found my niche making built-in cabinetry, though that market is only slightly bigger.

While I may be a moderately competent cabinetmaker, I often marvel at how many aspects of the trade I simply have not become adept at, like turning, carving, veneering, even finishing. Of course I’ve tried my hand at all these and still do, but self-employment requires wearing so many other hats (selling, designing, purchasing, bookkeeping, managing, to name a few) that being resourceful is really the overriding skill required to earn even a modest living in this trade. That and resilience, which my grandfather exhibited far beyond me, working with one arm through the Depression and beyond.

Tony O’Malley makes furniture and cabinetry in Emmaus, Pa.

From Fine Woodworking #287

|

|

|

|

|

Log in or create an account to post a comment.

Sign up Log in