Steam-bend a spiral

Helical legs and a conical shade combine in a beautiful lamp.

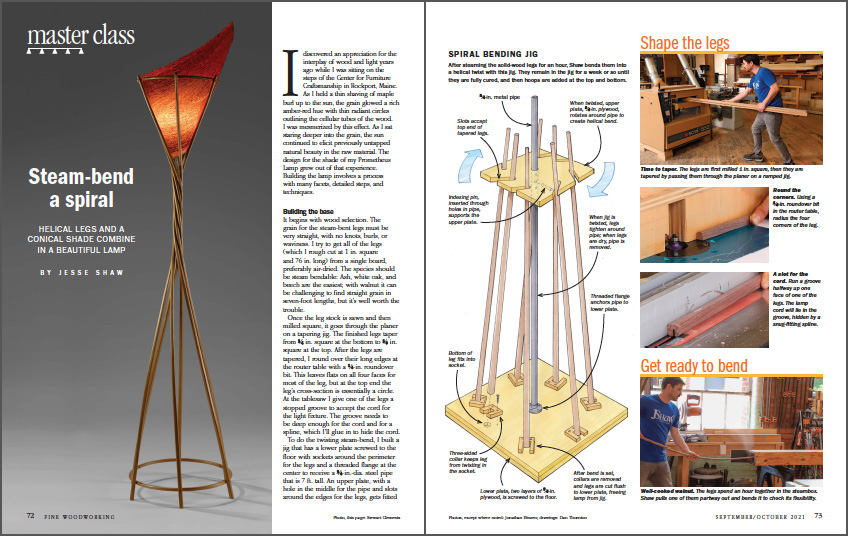

Synopsis: The twisted legs on Jesse Shaw’s Prometheus lamp are made possible by steam-bending. After steaming the solid-wood legs, a twisting jig is used to bend them all into a helical shape. After they are fully cured, hoops at the top and bottom keep the lamp base in shape.

I discovered an appreciation for the interplay of wood and light years ago while I was sitting on the steps of the Center for Furniture Craftsmanship in Rockport, Maine. As I held a thin shaving of maple burl up to the sun, the grain glowed a rich amber-red hue with thin radiant circles outlining the cellular tubes of the wood. I was mesmerized by this effect. As I sat staring deeper into the grain, the sun continued to elicit previously untapped natural beauty in the raw material. The design for the shade of my Prometheus Lamp grew out of that experience. Building the lamp involves a process with many facets, detailed steps, and techniques.

Building the base

It begins with wood selection. The grain for the steam-bent legs must be very straight, with no knots, burls, or waviness. I try to get all of the legs (which I rough cut at 1 in. square and 76 in. long) from a single board, preferably air-dried. The species should be steam bendable: Ash, white oak, and beech are the easiest; with walnut it can be challenging to find straight grain in seven-foot lengths, but it’s well worth the trouble.

Once the leg stock is sawn and then milled square, it goes through the planer on a tapering jig. The finished legs taper from 3/4 in. square at the bottom to 3/8 in. square at the top. After the legs are tapered, I round over their long edges at the router table with a 1/4-in. roundover bit. This leaves flats on all four faces for most of the leg, but at the top end the leg’s cross-section is essentially a circle. At the tablesaw I give one of the legs a stopped groove to accept the cord for the light fixture. The groove needs to be deep enough for the cord and for a spline, which I’ll glue in to hide the cord.

To do the twisting steam-bend, I built a jig that has a lower plate screwed to the floor with sockets around the perimeter for the legs and a threaded flange at the center to receive a 3/4-in.-dia. steel pipe that is 7 ft. tall. An upper plate, with a hole in the middle for the pipe and slots around the edges for the legs, gets fitted over the top end of the pipe. A series of holes drilled crosswise through the upper section of the pipe lets me insert a dowel to support the upper plate at various heights. When I bend the legs they wrap around the pipe, and after they cure I pull out the pipe and replace it with a 1-ft.-long dowel made from the same species as the legs and drilled out to accept the cord.

From Fine Woodworking #291

To view the entire article, please click the View PDF button below.

|

How to bend wood to your will |

|

The Magic of Hot-Pipe Bending |

|

Lamination Bending |

Fine Woodworking Recommended Products

Ridgid EB4424 Oscillating Spindle/Belt Sander

Comments

How stabile is the lamp?

Log in or create an account to post a comment.

Sign up Log in