Video: Making tapered wedges on the table saw

Contributing editor Chris Gochnour demonstrates how he creates wedges at the table saw using just a miter gauge and a stop block.Wedged mortise-and-tenon joints are a perfect way for woodworkers to amp up both the strength and style of their joinery.

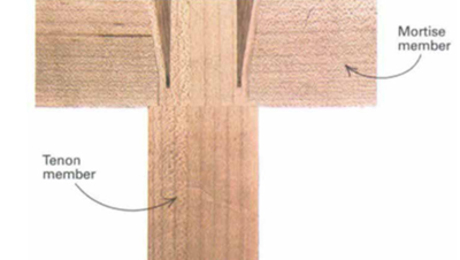

For structural purposes, wedging a mortise-and-tenon spreads the tenon, creating a joint that is tighter than you would otherwise be able to achieve—that is, if you want to be able to put the joint together. Windsor chairs—many of which are still going strong 200 years later–rely on this joint to lock the legs into the seat. Aesthetically, wedged mortise-and-tenons let woodworkers add to the visual presence of a piece. Use the same wood as the tenon, and you add a very subtle flair. Use a high-contrast wood, and you can add a visual statement.

When making the wedges, it’s important to keep the grain running through the length of the wedge; otherwise, your wedge will fall apart before you even try to hammer it into the tenon. Most woodworkers turn to the bandsaw to create these wedges. Michael Fortune’s bandsaw jig for making wedges is simple and effective, which is why it can be found hanging near bandsaws all over the world.

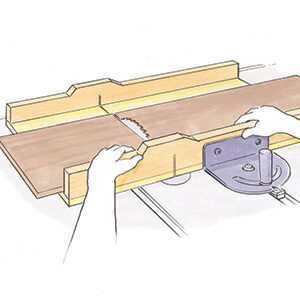

In this video, contributing editor Chris Gochnour demonstrates how he creates wedges at the tablesaw. In fact, Chris’s method doesn’t even use a specialized jig, just a miter gauge and a stop block.

Once you see how simple it is to add wedges to your through-mortise-and-tenons, you’ll likely want to make these wedges by the dozen. Thankfully Chris’s technique makes it just as easy to make a batch!

|

Making Wedges for Through-Tenons |

|

5 Essential Bandsaw Jigs |

|

From the archive: Designing the wedged mortise-and-tenon |

Comments

Is this a snippet from an upcoming video workshop?

Nope, but that's a good idea!

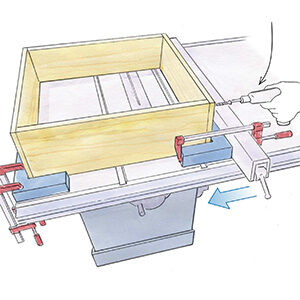

I've never seen that type of table saw fence, is that a modern contrivance or some old thing that's no longer available?

Delta Unifence. No longer available sadly.

I don't believe that is a standard Delta Unifence. I Googled Delta Unifence and all the images that show up are like mine. I have attached a photo of my Delta Unifence so you can see what it is like. I suspect Chris Gochnour has obtained a modified part that rides on the table saw table for his fence, probably an extruded aluminum profile. I would really appreciate if you could check with him and if possible let us know where or how he got it. It would allow attachment of a lot of the fence attachments shown in FWW, which cannot be attached to a standard Delta Unifence. Thanks in advance.

A very useful technique! Thank you FWW!

Since I don't have a miter gauge or retractable fence, I can easily adapt this technique to my shop, by just shimming my crosscut sled the fence of at a sight angle, and clamping in a stop block to safely produce consistent wedges!

I find these methods better than the one using a slotted sled thingy (here's Tom's take on it for the bandsaw, I've seen others for the table saw). https://www.finewoodworking.com/project-guides/beginner-projects/preparing-wedges-virtual-workshop-ep4

I prefer Steve's technique as the cutoffs are not pinched at the blade, making for a safer cut. It also produces better cuts because the work piece is held firmly all the way through the cutting process.

When you saw across the tenon to be wedged, do you cut a single saw kerf or do you cut a “V” into the tenon to accommodate the loose wedge? Also, is it necessary to have a small hole drilled at the base of the tenon to prevent initiating a split in the tenon and workpiece?

I had the same question but in my experience, after trying it both ways, is that if the wedge is cut to the right thickness you only need a sawcut for the slot and no hole drilled at the bottom since the tenon is captured in the mortise thereby preventing any splitting. If the tenon is a snug fit to start with the wedge thickness only needs to be slightly thicker than your saw kerf to 'lock' the tenon in place, assuming both will be glued in. I am sure there are other thoughts on this but I am so far satisfied with my results doing it this way.

Thanks!

Agreed. Thanks!

I use that same technique but instead of doing it on my table saw I use my band saw. Small kerf results in less waste and there's no chance of a wedge getting caught and flying back at you.

I have the same table saw but like bc-driftwood, my aluminum guide is slightly different, but I can still use the sliding aspect for the fence to avoid the pinch. I do not know why I never thought of that approach. That is way more streamlined over clamping a piece of wood to the fence.

Now I am also wondering if I could modify the unifence to accept 4080 aluminum extrusion…hmmm.

Edit: I found the same fence piece as pictured in the video. It’s called a Uni-T-Fence. I found it at https://www.ptreeusa.com/tablesaw_unifence.html, but it is out of stock at the moment (maybe forever?), but will be watching.

Log in or create an account to post a comment.

Sign up Log in