4 tool mods from Chris Gochnour’s shop

Four simple tool modifications that help Chris Gochnour get the most out of the tools in his shop.Micro-adjust for a tablesaw fence

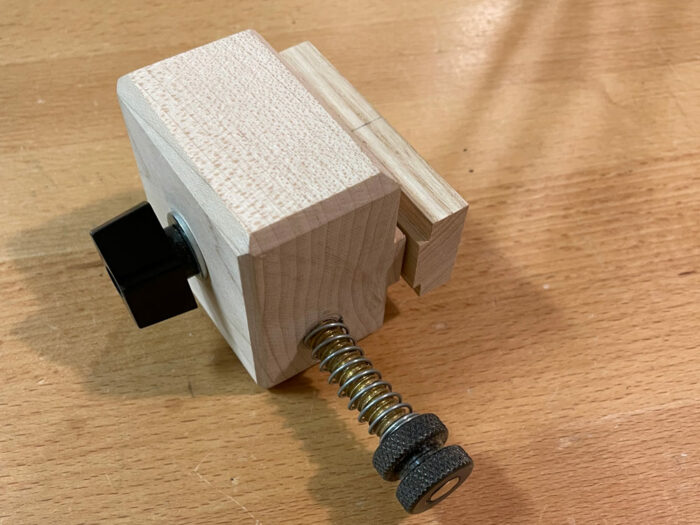

This micro-adjust for my Unisaw is a simple block of wood painted black. I started with a larger piece of wood and cut a profile that matches my tablesaw fence. It has a thumbscrew that is attached to a flange. I drilled and threaded a hole through the block, and inserted a 5/16-in. rod screw through it. A spring keeps the rod in tension, so it doesn’t loosen with vibration. Lastly, on the end there is a nylon knob to make it easier to tighten.

|

|

*The Unifence lends itself to this concept better than most fences, but with a little imagination you can adapt it to just about any fence. In fact, in a pinch you could the the very same thing with a clamp, a block of wood, and a deck of cards.

A better drill-press light

This old Delta lamp came with the drill press many years ago, and works well. But sometimes it creates shadows, making it harder to see things, particularly with aging eyes. So I ran down to the hardware store and checked out their inventory of headlamps. I’m not even certain which model I have. I just know it was the cheapest one at about $9.

I removed the adjustable strap designed to go around your head and replaced it with a band of Velcro—making it really easy to put anywhere you want along that drill-press column. Sometimes I have it right in line with a bit, other times I put it up a little higher and tilt the head down onto the work. It casts a perfect amount of light right in the work area. A $9 addition to the drill press proved to be a wise investment.

Become a better woodworker overnight

The answer isn’t better tools or more tools,

or even more skills. It’s vision.

Drill rod upgrades accuracy

I’ve been doing a lot of drilling that required real precision, marking surfaces and then indexing the drill right into the hole. To complicate matters, those holes are on an angle. Initially, I had two different setups. One was a rod for setting the angle and the other was a point for positioning it. It was just a bit frustrating. So I thought, why not make something that serves two purposes? The smooth rod allows me to accurately set the table angle, and the point lets me position the workpiece perfectly. This simple little shop improvement made setting up angles and positioning drill bits a little bit better.

Tool for removing stubborn dowels and spindles

Everyone has experienced putting a dowel in a hole and and having it wedge itself in awfully tight. How do you get them out? I’ve seen people take pliers and twist the dowel, destroying it. It breaks all apart and leaves the piece down in the hole. The same thing can happen with a spindle if you’re not careful. These pliers can be adjusted for a nice, snug fit, clamped onto the dowel, and then as you rotate, the dowel easily comes out.

I got the idea from a Windsor chair maker here in town. He was using it all the time to remove tight spindles or to rotate them to position the grain as he wanted it. I got a couple of pieces of 1/2-in. angle iron about 3 in. long, took a steel rod, put it between the the two angles, and clamped it into the jaws of a pair of vise grips. Then I had a friend of mine weld a seam, securing the angle iron to the vise grips. Once that was done, I took some leather and glued it onto the interior jaws.

More by Chris Gochnour

|

Video: Making tapered wedges on the tablesaw |

|

Spokeshaves Can be Pushed or Pulled |

|

Chris Gochnour’s sharpening process |

Comments

Excellent ideas! The vise-grip, DP rod, and headlamp mods are going to happen here soon!

Trivial edit...

When you were setting the drill press table angle to 4 3/4 degrees by lining the rod up to a reference piece, I could notice that the reference piece was marked 3.75 in that corner.

Love the ideas! Thanks Chris

I just read the article about the table Chris referred to. I loved the details of that build. Nice to see this video with a little more detail about drilling the angles on the drill press.

A length of true, straight drill rod, along with a dial indicator, is what machinists use to check for run-out (wobble or, better yet, the lack thereof) of the spindle on a drill press. (Can also be used on a mill.) I've been using one I inherited from my father for decades and now, with the advent of digital angle indicators with a magnetic base, I find it extremely easy to also check the angle of the spindle's alignment with the drill press table as well as whatever's clamped to it.

Chris, you Don have any additional written details/drawing on your micro adjust jig?

Thanks,

Aaron

I love all of them. I will put 2 of the micro-adjust stops on my table saw. One will be on the left of the fence. This will give me the ability to quickly change between 2 cut sizes. I know we normally try to cut everything with the same size all at once. Sometimes, that isn't possible. Putting the 2nd block will help.

Nice idea!

Not sure if the close captioning is needed, but it sometimes covers something in the video. I've been seeing that in several of your new videos.

There's a CC on the lower right of the video. You click there and then turn off the captions. I know what you mean.

Love the vice grip clamp. Thanks Chris!

Log in or create an account to post a comment.

Sign up Log in