Q&A: Cracking crotch veneers

Try out this solution for any issues with stubborn veneers.

I am having a major problem with small checks (cracks) developing on the surfaces of crotch-mahogany veneers. The checks are small but numerous and are across the grain on all surfaces of the small boxes I’m veneering. I apply a multi- layered finish as follows: a coat of an oil mixture consisting of double-boiled linseed oil and pure turpentine, two coats of orange shellac, two coats of sanding sealer, wood-paste filler, three or four thinned coats of sanding sealer and two coats of sprayed-on lacquer. When the lacquer is dry, I buff it with rubbing compound and finish up with some paste wax. The checks don ‘t appear immediately after the finish is applied, but show up on a gradual basis, some developing months and years after the boxes are complete.

-WT. Cosway, Halton Hills, Ont., Canada

Frank Pollaro replies: I used to have similar problems with crotch-mahogany veneer. However, the techniques that I’m currently using have practically eliminated this problem for me.

First, I coat the veneer with a solution of two-parts white glue, three-parts water, one-and-a-half parts glycerin and one-part denatured alcohol. You can also use this solution for any other stubborn veneers.

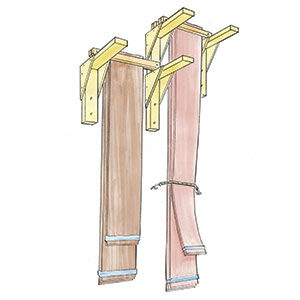

I liberally brush the mixed ingredients on both sides of the veneer. I then press the coated veneers between cauls of medium- density fiberboard (MDF), using sheets of plastic to prevent the veneers from sticking to the cauls or to each other. I apply weight gradually, not with clamps, to give the veneer a chance to absorb the mixture. After two days, the veneer should be flat and workable. It may still be damp; however, this will not affect cutting, gluing or pressing the veneer. I use white glue because it has a longer working time than yellow glues.

Second, I’ve found that crotch veneers work better when applied over another veneer. Although I don’t think grain direction matters, it’s better than gluing the veneers directly onto flakeboard or MDF.

Third, and most important, after the veneered piece is pressed, I sand lightly to remove any surface glue and then apply a thin coat of hot hide glue with a paint brush. This sizing fills the pores and, I suspect, inhibits the movement of the veneer to reduce checking. When dry, I sand the surface and finish. The hide glue will not affect finishing.

I’m also concerned with the finishing techniques you’re using. I see no need to mix oil, shellac, lacquer and wax on a single project. Three or four coats of Waterlox transparent, a thin wiping varnish available from most hardware stores, would surely give you all you are getting from these other ingredients with much less time and effort. It can then be rubbed and waxed using 0000 steel wool to give a lustrous satin finish.

Frank Pollaro gives workshops on veneering and is a designer and builder of fine furniture in East Orange, NJ.

From issue #107–July/Aug 1994.

|

Introduction to Wood Veneering |

|

Book-matched Veneer Panel |

|

Hammer veneering with hide glue |

Fine Woodworking Recommended Products

Bahco 6-Inch Card Scraper

Whiteside 9500 Solid Brass Router Inlay Router Bit Set

Log in or create an account to post a comment.

Sign up Log in