The jointer and planer are a team

Flat and square stock starts at the jointer to get one face flat then to the planer to get the opposite face parallel to it.Sponsored by Grizzly Industrial

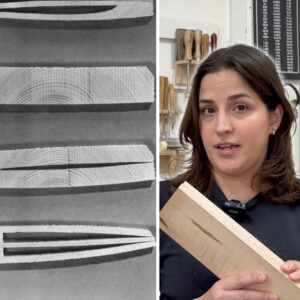

Going from rough lumber to finished, flat, square boards is a really important part of woodworking. There are different ways to go about doing it, but using a jointer and planer is a common method. There’s some confusion about the two different machines in terms of what they do and how they work together. The jointer has a cutterhead in the bed and is good for getting one face dead flat. If we were to flip the board over, we could get the second face dead flat, but it wouldn’t necessarily be parallel.

The planer does a really good job of getting one face parallel to the opposite face. This is OK if you’re starting with a flat board, but if you’re starting with wavy stock, all you’re doing is creating a parallel face that matches that same wave.

Together, the jointer gives us one flat face, and then the planer makes the opposite face parallel to the first. So start at the jointer to get a flat face, head to the planer to get the opposite face parallel to that, then go back to the jointer to get one square edge. And we’re off to a really good start.

|

A first look at our new shop |

|

Flattening Wood with a Jointer |

|

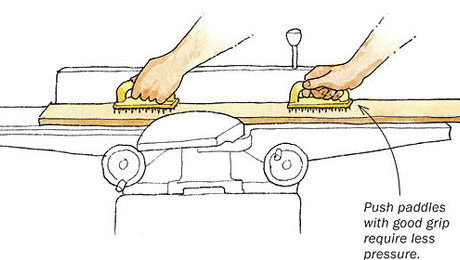

Jointer Push Pads that Don’t Slip |

Comments

Thanks for posting guys. Covering the basics every so often is always a good idea for new people who have joined! Those Grizzly machines are looking mighty tempting.

I 100% agree having both machines is best. But you can get by with just a planer. Think about how you flatten a board with hand tools. You use a scrub plane to get one face mostly flat and then work the opposite side to flatness checked by winding sticks. Once that is done you return to the original face. You can do the same thing with a handplane and planer. Get one side mostly flat, eliminate any rocking, and then use face down in the planer. As long as the board has enough reference surfaces touching the planer bed it will not be compressed by the rollers.

Was Mike tapping the heels of his work boots at the end?!? :-D

Really excellent video on milling rough lumber. At the moment, I only have a planer. Flattening takes a little work by wedging to make sure the piece doesn't rock and using a base board.

Being on a fixed income, my choices in new power tools are somewhat limited. But, researching benchtop jointers, I found that Grizzly has an 8" with spiral head for only $505. This isn't the true spiral head like Mike's. But, I can eventually get a Shelix replacement. It is out of stock until fall, so I still go about it the slower way. 😊

This is so funny: I have the exact same two machines. 😀 I think I've had that 1000 lb. beast of a jointer for over 15 years and it's still the favorite tool in my shop (they were a bit cheaper back then 😉). I recently got the planer after making-do for years with a lunch box. Both of them heavy-duty units made in Taiwan rather than the mainland.

I heard that we don't have ANY domestically made power tools. That's sad.

Not for the hobby / small shop market, no. I guess U.S. companies feel they have more profitable places to put their resources into than manufacturing products for this market on shore. I don't know if that's sad or not. Except for some high-end (and high $$$) stuff that's made made in Europe, it'll all made in Asia. Any equipment made here is for the industrial market.

I think it's a bad thing. I recently had to wait 3 months for Grizzly to get the 8" benchtop jointer back in stock. I suggested they might increase their sales if they could attach a "Made in USA" tag on their tools. The reply was that it was too costly. In the not too distant future China will have a stranglehold on us with all they produce.

I have had the same planner for three years but I always pick up tips when watching Mike’s demos. I am curious about one thing. I noticed that after adjusting the cutter head height on the planner, Mike then tightens the locking knob on the planner’s side. He seems to do this after each height adjustment. I’ve never done this and never have noticed the height change during operation. So Mike……why do you use the locking knobs?

Log in or create an account to post a comment.

Sign up Log in