Who needs a table saw?

Vic Tesolin asks the hard questions: Are tablesaws a vital component of a shop? And if not, what are your other options?

This topic ought to get the blood running. Who needs a tablesaw? Seems like a silly question—everyone needs a tablesaw, right? Most shops have been designed and built to have a tablesaw as the central fixture, especially since the affordability of tablesaws makes it possible for the average woodworker to own one.

I went about 10 years without one, that was until a good friend gave me his old one after upgrading to a new saw. I was hesitant at first to have one in my shop, but what the heck! I’m fortunate to have the space so I decided to give it a try.

Here are my observations.

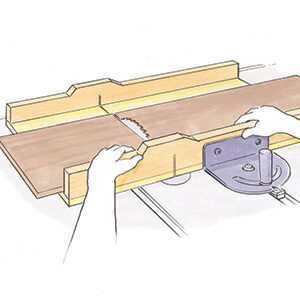

Before I had this saw, I had other tools that, fundamentally, did what the tablesaw does. I have a Festool track saw that took care of the ripping and crosscutting of wood and sheet goods. I love using this tool because it is so much easier to bring the tool to the wood rather than the other way around. I didn’t need to worry about extra space for infeed and outfeed and the dust collection that the track saw and vacuum offers is incredible. I can cut repeatably with the use of stops or parallel guides, and any rips that are too small get done on the bandsaw and finessed with a plane and shooting board.

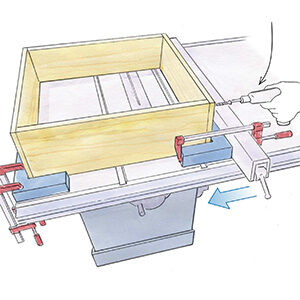

But what about joinery? My tenons are easily done with my bandsaw and the drill press can help with the mortises. Better yet, mortise-and-tenons can get done with a Pantorouter. As for dadoes and rabbets, I use the same Festool track with a router to make quick work of these tasks. Typically routers are a dust-belching annoyance, but the right tool with dust collection makes a huge difference. I personally find dado blades to be terrifying and prefer to not use them.

Now, when it comes to dollars and cents, owning a track saw, router, vacuum, and requisite jigs is going to set you back around $5,000 depending on the brand you choose. Most tablesaws worth their salt and can handle a dado stack are going to run any where from $2,000 to $7,000, again depending on the brand. Keep in mind that lower-priced tablesaws can’t run dado blades as effectively because of a lack of power, and often the arbors are just too short to handle a full stack.

I’m not suggesting that you change what you’re doing or that what I do is better. All I’m saying is that there are options out there that don’t take up as much space, don’t need 220v power (in a lot of cases), and aren’t responsible for as many injuries/amputations as the tablesaw.

Let’s not forget that you can skip all of these machines and work with hand tools. The inspiration and goal of writing my two Minimalist Woodworker books was to show folks that you don’t need power tools at all to make things out of wood.

Now that I’ve had a tablesaw for over a year, I think I am ready to part ways with it. Any takers? I’ll go back to my other ways of getting the work done. It was a fun experiment and I’m glad I gave it a try. I learned a lot about how I like to work and what is needed and not needed for me to do what I love. As the saying goes, in order to understand … you must do.

More from Vic Tesolin

|

Make your workbench your own |

|

Are you a wood shop tweaker? |

|

Are you packing a tool there, Bud? |

Fine Woodworking Recommended Products

Ridgid EB4424 Oscillating Spindle/Belt Sander

Rockler Dust Right 1250 CFM

Hedgehog featherboards

Comments

Thanks for the blog post.

I'm grappling with a similar decision. I've got a PM2000 with a LOT of add-ons. I think I can get the same work done with my track saw (Festool), bandsaw, router/router table, etc. but I just can't pull the trigger.

My other roadblock is I'm in East Texas and there doesn't seem to be much of a market for used tools unless one wants to give them away. I tried with a 16/32 drum sander and an 8" jointer and got no takers.

cheers.

It all depends on what you make. I do not do a lot of ply so a track saw is not optimal. I don't make a lot of small stuff. I normally work with rough cut hardwood. I do a lot of tables from dining room to side tables so a TS, jointer, and planer work great. There is no one answer to the TS need.

The same can be said for a mortise machine. I have done a lot of mortises with a router, works fine. I have hand chopped a few, too. But it is waaaay faster with my cheapo HF tool set up with an x-y vice. Cheaper than a Domino for my needs - which is a great tool BTW.

So I always am wondering about these posts.

"depends on what you make" - I definitely agree. Each time I go through these considerations I end up staying with what I have. I've had one since the mid 70's so having one is always conveniently available.

I've been married for 46 years and my wife always mentions how frequently I use a table saw. Maybe I should sell all my Festool stuff instead... but my wife also says I'm a tool collector, not a woodworker.

I think the question, "who likes broccoli?" would get the blood running more. Everybody picks what they think works best for them, at the time, or what they enjoy using.

I've had a Sawstop contractor saw for over twelve years now. I saved my money and spent some extra cash for the cast iron wings and better fence. I remember thinking the $1,500 at the time was worth having all my fingers intact. I use the blade guard at all times, except when using a sled. Last year I finally broke down and bought a 14" bandsaw to do some resawing and also some ripping. I have to admit looking at that spinning bandsaw blade knowing there is no built in safety measures, does scare the dickens out of me. I use my power tools mostly for initial stock prep, getting the lumber ready for my hand tools. All joinery, is done by hand. My planner is used to get me in the ball park, then hand planes do the final dimensioning and flattening. The hand tools are not only safer, but so much more quiet and stirs up much less dust. I enjoy hearing the sound my hand tools and stereo system provide much more than the power tools. Don't get me started on joiners and broccoli...

Peter Malard on YouTube has a nifty hinged piece of track saw "rail" on his MFT so that it allows his MFT to act like a chop saw. Not sure who came up with this trick but this is the first place I saw it.

https://youtu.be/0V-p5F7SjO4

I assume it was festool that came up with the trick since it's their product he's showing. That's pretty much exactly how a mft table works.

I agree with you Vic. When I started woodworking in earnest 4 years ago, I trained at a community woodshop with SawStop table saws. Loved them. But my home doesn’t have the room for one, so I went with the Festool MFT/3 and TS55. Have made large and small projects with precision. I also love the safety piece of mind also to know the kick-back risk is low and dust extraction is exceptional.

When I'm on my knees breaking down a sheet of plywood with a track saw, all I can think about is I can't wait until the pieces are small enough to get back to my beloved table saw, my beloved table saw sleds and various cutting jigs, etc. I'm assuming you have a gargantuan table where you do your tracksaw work. I don't have room for that even if I wanted it.

Respect to all table saw users. But I thought I’d mention my set up for plywood track-saw cutting in case others might find it helpful. Not my original idea. I have a set of table saws and 2x4s I set up, then lay four 2’x4’ plywood panels on top of that to create a large temporary 4’x8’ surface. Takes me 2 min to set up. I lay down 2’x2’ insulation foam panels on top of that, then add the plywood I want to cut. It’s all at waist-high level where I can see, save my knees and easily transfer pieces to my carts. It all folds up and tucks into the corner of my garage when not in use. I just don’t have room for a table saw and found this has worked well for me.

Sold my TS two years ago mainly because of space issues. Got a MFT and TS55 and haven't missed the TS. Works only from rough planks.

any saw is an indispensable tool for a man in the house.))

I tried to work with a tracksaw and bandsaw combo instead of a tablesaw when I first started, but ripping boards, especially narrow ones, and especially with repeat cuts, is nearly impossible on a track saw, even with a MFT-type table.

A band saw works for rips, but is awkward and finicky, and just not as precise and doesn't leave as good a finish as a tablesaw.

When I finally gave in and got a tablesaw, I really started to enjoy woodworking.

Log in or create an account to post a comment.

Sign up Log in