STL267: The router queen

Larissa Huff wows Vic and Ben with her harrowing tales of freehand letter routing and many other woodworking feats.This episode is sponsored by Shaper and Pony/Jorgensen

Question 1:

From Sriram:

I’ve noticed something recently about my projects. I plan them out quite carefully, but always seem to forget thinking about how I’m going to finish the edges until I actually get to that point. There is the aspect of breaking/softening the edges from the standpoint of making them less likely to splinter. But I’m more interested in how the experts think about the aesthetic aspects of finishing these edges. Of course, one can blindly use a roundover bit and just finish them that way, but a recent experience opened my eyes to other possibilities. I’d put a small chamfer on a piece using a block plane. I stepped back to take a look to see if it was uniform and the chamfer caught the light and lit up in a way that I had not observed before.

Question 2:

From Scott:

I just received a free delta unisaw with a sliding attachment!

Two question on this table saw:

1: Ben, this does not have a riving/splitter. I believe you added in to your unisaw which one and do you like it?

2: I want to rebuild my shop around this saw. Right now my table simply butts to my work bench which is also my out feed table. I would like to attach the bench/outfeed table to the saw but the floor is not level. (garages shop). Would you build to level? ie, level the saw and build everything to that plane or build to square with the floor.

|

ARK Shark Guard from Leeway WorkshopA riving knife for old cabinet saws |

|

Expert Lesson: Tablesaw SafetyBuild a simple but sturdy outfeed table, and learn important safety tips |

Question 3:

From Bojan:

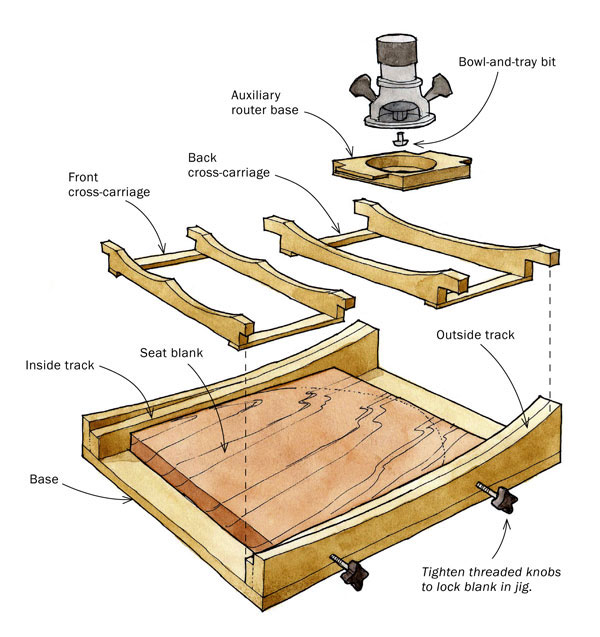

I’m thinking through a process of cutting an anticlastic curve out of solid wood to be used for a chair back. I can see how to create it as a bent lamination but am struggling to think it through out of solid lumber. Getting the curve in one direction should be simple enough but I cannot wrap my mind around cutting a second curve in it. Any ideas from the great minds of FW?

So far best I can come up with is trying a router jig that conforms to the original curve and guides a router into a path of the other curve.

Quick definition, if needed.

Anticlastic curve – Anticlastic surfaces are those in which the centres of curvature are located on opposing sides of the surface. This is commonly-described as a saddle shape. A hyperbolic paraboloid is an anticlastic surface. Think of a Pringle chip.

For a chair back, the one curve would hug your back and another would curve away toward the back to accept the curvature of the spine.

|

Shape Chair Seats with a RouterThe purpose of this fixture is to shape wooden chair seats so that they fit the body. |

Every two weeks, a team of Fine Woodworking staffers answers questions from readers on Shop Talk Live, Fine Woodworking‘s biweekly podcast. Send your woodworking questions to shoptalk@taunton.com for consideration in the regular broadcast! Our continued existence relies upon listener support. So if you enjoy the show, be sure to leave us a five-star rating and maybe even a nice comment on our iTunes page.

Comments

“[Deleted]”

I'm glad to see you've added Vic to the podcast. I really like and have a lot of respect for him as a woodworker. A few years ago when I retired and built a new shop, I bought his book, The Minimalist Woodworker, I got a lot of good ideas for setting up shop. I've also gotten a lot oot of his magazine articals. The only downside is we'll have to be careful or he'll have speaking metric!

I'm also glad for the addition of Vic. He is very informative and a good teacher. I enjoy hearing him talk, and his unique and interesting viewpoints, and even his jokes!

In a classic "forest for the trees" manner, I forgot to compliment having Larissa as a guest. She was delightful, knowledgeable, and well spoken.

I couldn't help but notice that the Polka Dot Box in the latest issue featured dimensions to a 64th of an inch and couldn't help but speculate that someone helpfully converted some pretty normal metric dimensions to these silly fractions. Perhaps your new host Vic would like to start the next podcast with a monologue on this travesty.

Last year I designed and built my outfeed table with these adjustable feet.

Welcome Vic!

I love you guys for getting Vic into the team!

Hi Ben, Interesting to hear you talking about milling down to 2mm. What's your method? Double-stick the lumber to a sled?

This Podcast is awesome and is the reason I got an unlimited membership. Vic is a great addition to the team and I’m excited for the future Pods. I am wondering if he could talk some about his pulling style hand plane he mentioned in a past article. Specifically how he feels about performance in comparison to a “traditional krenov” style. As well as bed angle selection for either style.

I am wanting to build a collection for myself and can’t decide if I want to push or pull the plane.

Thanks,

Josh

Vacuum lamination in my opinion would be the easiest way to make an anticlastic curve. I haven't made a saddle shape, but I've made many skateboards. I think a saddle shape would be even easier than the bowl shape of a skateboard. You don't need positive and negative forms. Create the form from foam wall insulation. I like to start with a belt sander to get the rough shape and finish up with a Sureform plane. Stack up your thin glued layers, tape them to the form and stick it in a vacuum bag for a while. It's amazing how much pressure you can exert with a vacuum bag. If you run the grain in the same direction on all the plies, it will be hard to distinguish it from a solid piece of wood, especially if you cut your own veneers from the same board and keep them in order.

Log in or create an account to post a comment.

Sign up Log in