Boiled linseed oil

A durable finish that's both versatile and inexpensive.

Linseed oil—pressed from the seeds of the flax plant—has been used by woodworkers and artists for thousands of years. It’s versatile and inexpensive. In its raw form, mixed with pigment, it makes artist’s oil paint. When heated, it makes a good penetrating wood finish.

Linseed oil is known as a drying oil because it reacts with oxygen and eventually forms a hard film. Chemists call the process polymerization. (Tung oil, from the seeds of the tung tree, is the other widely used drying oil.) Canola oil and olive oil are two types of nondrying oil. They never solidify to form a film, which is why they are better for cooking than cabinetmaking. Between those extremes are semi-drying oils, such as soybean and safflower, which are used to make varnish.

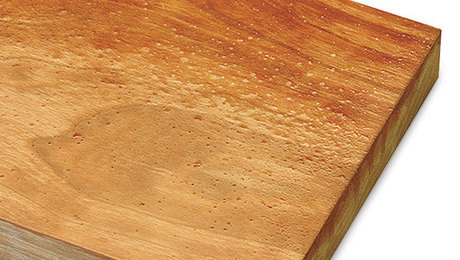

There are several varieties of linseed oil. The one that woodworkers most often use is boiled linseed oil, or BLO. It makes an excellent, durable finish that darkens as it ages. Tung oil is even more durable and darkens the wood less.

BLO is also one of the ingredients in the mixture known as Danish oil, along with varnish and a solvent such as turpentine or mineral spirits. The varnish allows Danish oil to form a thicker film than BLO alone. Waterlox is a similar oil-varnish mixture, made from both linseed oil and tung oil.

Despite its name, BLO isn’t boiled, but it is heated. Most brands of BLO are mixed with heavy-metal driers, typically salts of cobalt and manganese. Those additives speed BLO’s reaction with oxygen, allowing it to dry in a day or so. Raw linseed oil, without the heating and the additives, can take weeks to dry.

Like other oil finishes, BLO is insanely easy to apply: Hand-sand the piece you’re finishing to at least 220-grit. Wipe on the oil with a cotton rag and wipe off the excess. Wait a day, lightly burnish the surfaces with a gray nonabrasive pad, and apply another coat of oil. Repeat until you get the feel and sheen you want. Just don’t expect an oil finish to build like shellac or wipe-on poly. The oil penetrates the wood instead of sitting on top of it.

Oil finishes present the hazard of spontaneous combustion. Wadded-up oily rags will absorb oxygen, starting a chemical reaction that generates enough heat to make the rags burst into flame. That’s a certainty with BLO, less of a certainty with tung oil. Some sources maintain that tung oil isn’t likely to burn because it has a high flash point. But why risk a fire? If you’re using a finish that contains BLO or tung oil, spread the rags out on the ground or hang them on a rack until they’re dry. Only then can you safely discard them.

There’s one other concern with BLO: food safety. Because most brands of BLO contain heavy-metal driers, they aren’t considered food safe. So if you want an oil finish on a butcher block or cutting board, or on a carved spoon or a turned serving bowl, choose something other than BLO. For example, The Real Milk Paint Co. sells a pure tung oil that’s food safe. Woodturner Mike Mahoney sells a heat-treated walnut oil that dries quickly and is food safe. Or, use a brand of linseed oil that doesn’t contain potentially hazardous ingredients. These include finishes from Tried & True and Odie’s Oil (a brand favored by woodturners). The maker of Waterlox says the finish is food-safe when dry.

For more information on oil finishes, check out our Finishing Guide.

|

Pros and Cons of Oil Finishes |

|

Removing Sticky Boiled Linseed Oil |

|

One Fast Finish |

Fine Woodworking Recommended Products

Bumblechutes Bee’Nooba Wax

Diablo ‘SandNet’ Sanding Discs

Log in or create an account to post a comment.

Sign up Log in