STL270: Should I get a shaper? Oh..

Steve Latta and Bob Van Dyke join Ben to talk about marquetry, banding, and workshop injuries.This episode is sponsored by the Society of American Period Furniture Makers

Question 1:

From Chuck:

Dear sirs, I have a request to make a fairly small kitchen table. I am famous in my family for making favorite pieces. I have made quite a few pieces with inlay banding and it is easy to do and looks good.

Here is a wood movement question, running a banding along the grain, no problems; however across the grain I’m afraid it will buckle or snap as the wood moves. Could you cut the banding in smaller pieces and each segment would move on it’s own or should I take a different approach. I’ve also thought of making it out of 3/4 Baltic Birch ply and veneering the whole thing and wrap the edges with solid wood to hold up for the inevitable banging from use. Which way should I go? I listen to your show and have been a subscriber to Fine Woodworking for many years.

|

How to make a sinuous, tapered string inlay |

|

String Inlay Made EasyTwo simple, shopmade tools make the slits and the stringing |

Question 2:

From Jordan

I love the show. You are all a great inspiration for me when I get stuck mentally between projects. Committing to starting the next big project is a challenge of mine. Thank you for the great material you produce, digitally and physically.

My question: in episode 231, Mike and Ben discussed the benefits and draw backs of router tables, but thumbing through the Grizzly catalog I see 1-3 hp shapers for equivalent prices to nice router tables. Why should I invest in a standalone router table verses an equivalent cost and power shaper?

The shapers seem more robust and a more coherent package.

|

Consider a ShaperEven if you have a good router table, you may need this powerful machine |

|

Router Table is Better for Small Shopsby Rollie Johnson |

Question 3:

From Ed

The latest Shop Talk Live #217 was especially informative and interesting. The discussion regarding the steps one should follow from initially bringing lumber into the shop to working it to its final dimension to equalize its moisture content with that of the shop reminded me of something I read in a past article in FWW by Steve Latta.

Accompanying a picture of Steve in the middle of dropping a piece of lumber to the floor, there was a caption stating that the shock of hitting the floor would tend to relieve the internal stresses built up in the wood during the drying process. This little trick would add to my confidence that I could then clean up the piece to its final dimension.

|

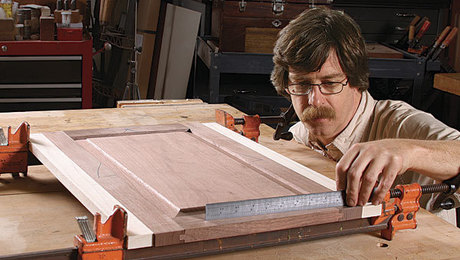

Frame-and-Panel Doors that Stay FlatHow to ensure that your frame-and-panel doors come out flat—and stay that way |

Every two weeks, a team of Fine Woodworking staffers answers questions from readers on Shop Talk Live, Fine Woodworking‘s biweekly podcast. Send your woodworking questions to shoptalk@taunton.com for consideration in the regular broadcast! Our continued existence relies upon listener support. So if you enjoy the show, be sure to leave us a five-star rating and maybe even a nice comment on our iTunes page.

Comments

The question on the shaper is a good one. I have a SCM combination machine that comes with one. The machine also comes with a sliding table. I have mostly used it for cutting tenons (ironically my computer just tried to autocorrect "tenons" to "tendons", so no not tendons). I mount two blades with a space between them. Yesterday I mounted a thin kerf saw blade and used it to cut grooves for splines. Similarly for cutting kerfed keys on metered boxes. I like that option because I prefer putting the piece flat on the table rather than balance the board on edge and running them through the saw.

Log in or create an account to post a comment.

Sign up Log in