Adjustable sled runners

A quick, easy, and cheap option that stands the test of humidity.

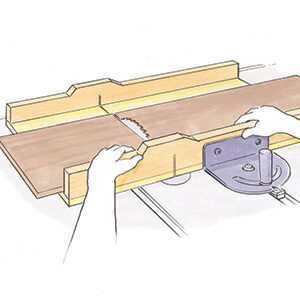

Making adjustable miter gauge runners

When making sleds for the tablesaw or to fit similar guide slots in other tools, I’ve always made the runner myself. The advantage of course is that they are quick, easy, and cheap. They never leave me waiting for the UPS truck to arrive, and there’s satisfaction in having made them myself.

On the other hand, being made of hardwood, they can swell to a tighter fit or shrink to a looser one in response to changes in humidity. These changes can affect ease of use and accuracy. So, here’s a way to make hardwood miter-gauge runners in your own shop that are adjustable to a perfect fit even when you’ve had extended periods of extreme moisture in your woodshop and your runners were made in a drier time. Or vice versa.

Use hardwood of the length you desire for the jig or sled you’re making. In my case, I used cherry and milled it to the following dimensions: 3/8 in. thick, 11/16 in. wide and 13 in. long. Use a drill press and 11/32-in. brad-point bit to drill holes along the edge of the stock. Be certain that the drill is centered in the stock. Using a fence on the drill press will give more accurate results. Mark and drill these holes 1-1/2 in. from the end of the stock and at center on each piece. The holes should be drilled 1/16 in. deep allowing the head to sink into the stock. Use the depth stop on the drill press to control depth.

Next, put a 5/32-in. drill bit in the drill press and adjust the depth so that the drill will pass completely through the stock. Use the fence and the center of the previously drilled hole to guide the placement of the stock on the drill-press table. Use an 8-32 tap to form threads in the holes for the plastic screws to fit. I mounted the 8-32 tap in a cordless drill and cut the threads in each hole, slowly in and out to keep from stripping the threads. The tap is intended for use on metal so be careful to not drive it in so far that it strips out the threads.

If you use 3/4-in.-long nylon screws as I did, you’ll need to turn them all the way into the stock and then use the stationary belt sander to sand them flush on the opposite side. Use a screwdriver to adjust them for a perfect fit before mounting them to a sled base. After mounting you can adjust the screws for a smooth friction-free slide through the cut. The nylon screws will see to that. The nylon screws I used are from Amazon, Hillman stock number 59463-L.

|

Crosscut Sled for Large Panels |

|

Build a Simple Crosscut Sled for the Tablesaw |

|

Tablesaw sleds for joinery |

Fine Woodworking Recommended Products

Forrest Woodworker II Blade

Rikon 10-3061 10-in. Deluxe Bandsaw

The saw has two speeds: 3,280 sfpm (surface feet per minute) for wood and 1,515 sfpm for soft metals and some plastics.

Ridgid EB4424 Oscillating Spindle/Belt Sander

Comments

Thanks, Doug. I like this idea. Just a heads up, the Amazon link is for #10-24 nylon screws....not the #8-32 that are referenced in the article.

I've thought about doing something similar with spring plungers. I know the OP said this can be done without waiting for a delivery truck but if you're willing to order the nylon screws from Amazon then getting a spring plunger from McMaster Carr, Grainger or similar probably isn't too onerous, either

Log in or create an account to post a comment.

Sign up Log in