Workshop Tip: Turn any chisel into a dovetail chisel

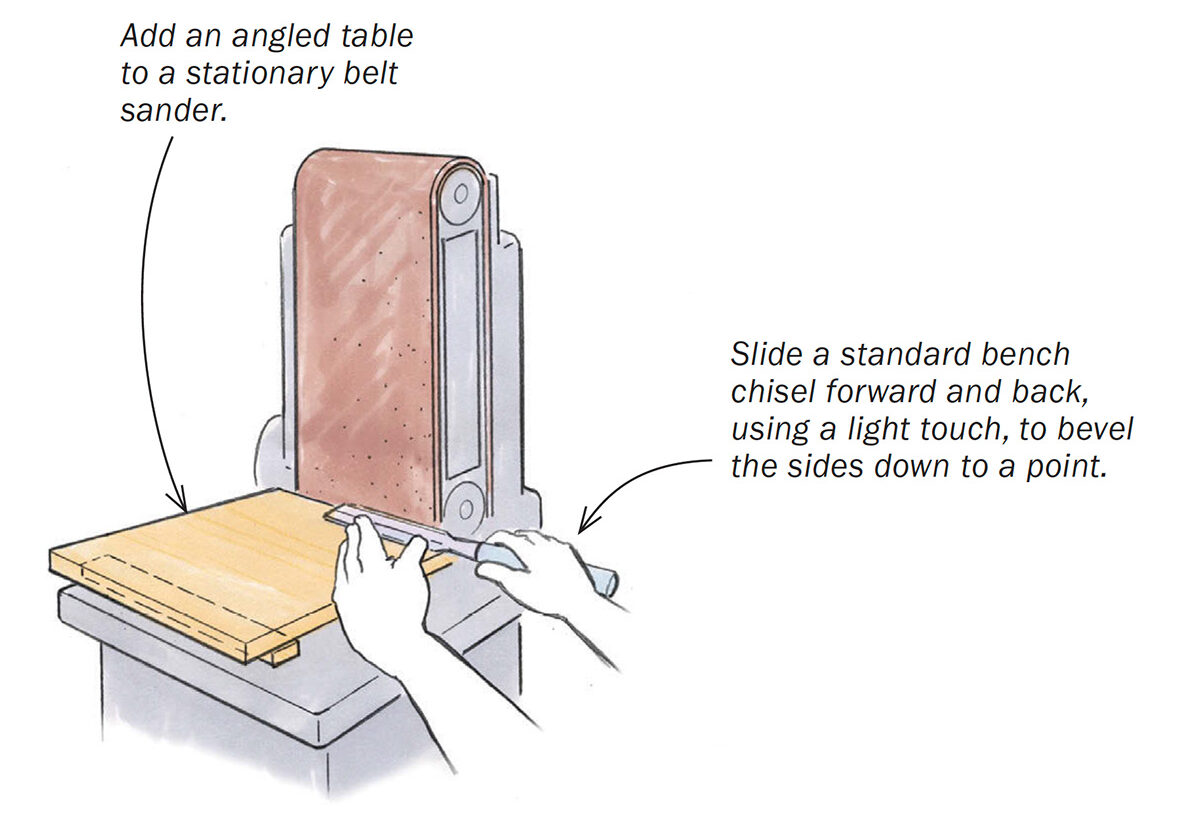

A stationary belt sander easily removes flat areas so chisel will fit nicely into the corner of a dovetail socket.

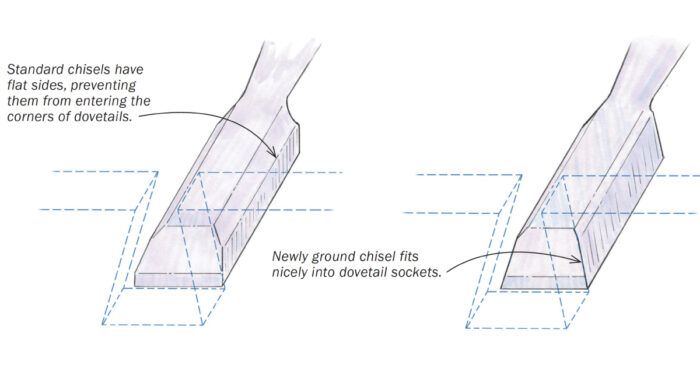

A dovetail chisel has angled sides, letting it nestle nicely into the corner of a dovetail socket. Standard bench chisels have flat areas at the sides, called “lands,” which prevent them from working all the way into the corners, and can make obvious dents there. To turn a bench chisel into a dovetail chisel, many folks use a bench grinder, which requires a steady hand to produce a smooth, even result. A stationary belt sander makes the job a lot easier. Start by creating an angled bed as shown, using a piece of plywood. The angle of the bed should match or exceed your favored dovetail angle. Slide the chisel forward and back against the belt, with a light touch, and stop just as the angled side reaches the bottom of the chisel. You’ll love the results. For Japanese chisels, you can use a black-oxide coating or other patina solution to turn the freshly ground metal black.

—DEREK COHEN, Rossmoyne, Western Australia

Illustrations by Dan Thornton

From Fine Woodworking issue #299

Fine Woodworking Recommended Products

Bahco 6-Inch Card Scraper

Veritas Micro-Adjust Wheel Marking Gauge

Veritas Precision Square

Comments

Clean out your sander before you try this and have a fire extinguisher handy anyway.

This will produce a shower of sparks right down into where fine dust cakes up in the sander. I had to put my sander out after using it to square up the edge of a plane iron last year. It didn't take much more than a few touches before I saw tiny curls of smoke.

Anything remotely like fire would be unusual in my experience. I have ground many chisels like this, and never even getting the steel more than warm. You must be using very high grit and excessive zeal! Regards from Perth, Derek.

Log in or create an account to post a comment.

Sign up Log in