Gentle on my mind

Whether you're marking, sawing, or chiseling, a light touch is often the key to success.

While I appreciate a willingness to attack the work, that can mean you’re trying too hard. A little less effort—a lighter touch—is often the key to success in woodworking.

Think gentle.

The most obvious example is in learning to use a handsaw. A loose grip and almost no downward pressure is key to getting the cut started. And once you’re into the cut, letting the weight of the saw do the work—instead of forcing the cut with hand and arm pressure—will usually give you better results.

I see it all the time in dovetail transfer, too. It is far more accurate to make a series of light passes with your knife while tracing the shape of the tails (or pins, if you’re one of those crazy pins-first folk) than to push down hard and make a deep line in one go (and anyway, you don’t need a deep line). Push down too much and you’re likely to wobble your knife, or follow a grain line instead of getting a good transfer. If the knife pops down off the edge of the mating board as you finish the cut, you’re pushing far too hard.

The same is true when using a marking gauge or cutting gauge, as when laying in the baseline for the aforementioned dovetails. When you come off the edge of the board as you finish the pass, your gauge should basically stay in the same plane as the work; if it dives down off the edge, you’re pushing down too hard.

Push too hard, and you likely won’t keep the fence of the gauge registered at a perfect 90° off the end—and that results in a wobbly baseline, which in turn makes it more difficult to cut a crisply fit joint. Plus, the cut itself can be ragged, even if it is straight. Think about how you cut a sandwich slice from a loaf of bread: Try to slice it in one go and the bread fibers will mash. Make a series of passes with the knife, and you’ll get the perfect slice (assuming you’re using the correct knife and it’s sharp, just as with a woodworking tool).

Cut with class.

Another thing I teach in most classes is what Robert Wearing (in The Essential Woodworker) called a first-class saw cut, for cutting the half-pins on the outside edges of tail boards:

“First-class sawing is used for all really important work, particularly the shoulders of the mortice and tenon joint, and accurate work will already have been marked out with the knife. Deepen the knife cut right across the width of the piece. Holding it in the vice, chisel a shallow groove. This should be nibbled out with a wide chisel using tiny cuts for which no appreciable strength is needed.”

Key in that passage is “no appreciable strength.” Inevitably, students reach for their mallets when in fact a slight push with a sharp chisel from the waste side into your well-marked baseline should do it.

Use a (sharp) chisel wider than the work.

Raise the chisel to maybe 25°-30°, then push in – gently.

Et voilà!

And with that, you’ve already cut the show surface as well as created a wall against which to register your saw as you cut away the rest of the half-pin waste. But if you push too hard with the chisel, you’ll cross your baseline. That results in a gap right where it will show the most, if it’s the top edge. Gentle does it.

I see the same problem in tool chest classes, when we use a plane blade to mark the baseline off the finished carcase. With two opposing corners dovetailed, clamp one of those assemblies to the case, flush with the bottom boards (or offcuts thereof as shown below).

Ready to mark the baselines!

Register the blade on the side of the planed case, and gently draw it down at an angle, using the corner to mark the baseline on the skirt board. Then repeat, and repeat again if necessary. As with the marking knife and cutting gauge, the line will be more crisp if you use a series of light passes. You should not be popping off the bottom of the board as you come out of the cut.

More from Megan Fitzpatrick

|

‘Work slower; it’s faster’ |

|

Learning how to saw by hand |

|

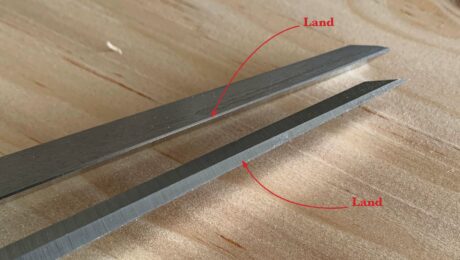

My lands! You shouldn’t buy just any chisels |

Fine Woodworking Recommended Products

Olfa Knife

Tite-Mark Marking Gauge

Suizan Japanese Pull Saw

Comments

The outside edges of dovetail boards is about the only use I have for a 1" chisel.

It's what I use mine for most often, too.

Great illustration of a chill approach and a helpful reminder. Thanks!

Great advice for those still developing habits. I used to be *way* heavy handed with the marking knife and dovetail saw. Now I’m just ordinary heavy handed. Must remember to focus on light handed. It always seems to go easier with the light approach.

Is it a Venus vs Mars thing? Guys tend to rely on muscle to solve problems while gals tend to rely on technique and finesse. We all get better as repeated good technique gets cemented into muscle memory which improves efficiency. But practicing poor technique cements that in as well. And of course, it is easier to instill good technique from the beginning than to correct bad habits.

We need more women learning and teaching woodworking!

In my teaching experience, it seems to be more age related than male v female. Younger people are more apt to listen (or at least have less trouble applying the lesson)

Log in or create an account to post a comment.

Sign up Log in