Do you need a 3D printer in your woodshop?

Do you need router templates? Dust collection hose adapters? Throat plate inserts? Then maybe the answer is yes.

Why in the world would someone be writing about 3D printers—glorified robotic hot-melt glue guns—on a woodworking website? Well, I’m here to tell you that my 3D printer has become an integral part of my woodworking life. I get a lot of questions about it any time I mention 3D printing on the podcast or on Instagram, and I keep promising to write about my experiences, so here we are.

You don’t always know how often you’ll use a tool until it’s in your shop. I didn’t realize how often I would use my 12-in. disc sander until it was in my shop ready to go at a whim—my 3D printer was the same. My humble 3D printer was an early Covid purchase. My wife and I want our son to grow up around an array of technologies and crafts. She is a weaver, and I am a woodworker, but we both thought it would be good if he learned about digital manufacturing alongside the (dare I say “legacy”) crafts he witnesses daily in our house.

I consider myself as much a “maker” as I do a woodworker, and I’m pretty computer savvy, so adding a 3D printer didn’t seem like too much of a reach for our household. Like most, upon getting the printer I immediately started printing junk I downloaded from the internet—tchotchkes at best. As I got more comfortable with the craft, though (and eventually CAD modeling programs), the printer suddenly opened up a new world to my woodworking.

- Need a specific template to mount a router lift you got from Facebook marketplace? Print it!

- Need throat plate inserts to mount in that router lift (it was only $100 after all)? Print them!

- Need an adapter to connect your Festool vacuum hose to… well… anything? Print them!

Dust-collection adapters alone are worth the price of a 3D printer. I hadn’t thought of the idea until seeing Marius Hornberger’s video below, which I credit for getting the 3D printing bug planted in my brain.

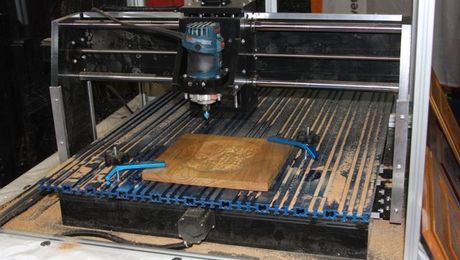

While I do consider myself a 3D printing enthusiast, my printer has become a huge asset to my set of woodworking tools. I love CNC machines and other high-tech tools like the Shaper Origin, but a 3D printer allows me to make templates and parts so easily I don’t yearn for one in my personal shop*. You’ll never find a 3D printing “how to” on FineWoodworking.com (this isn’t the place for that), but in upcoming posts I’ll share some prints (and files) that I have found useful.

Below I’ve linked to the printer I use. We can talk more about printers eventually, but I think it’s good to start simple and the Ender 3 pro in my shop has been a champ for two years now. I know woodworkers like to buy their last tool first, but I really recommend starting with a simple printer and printing with PLA filament. Keep it simple, and you can always go bigger and better later. The items linked below are what I use for all of my functional prints in the woodshop.

If you have any that you’ve found please let me know in the comments below!

*It should be noted that we are going to be covering a lot more of the conventional “digital woodworking” tools in the new Fine Woodworking shop soon! We’ve created this blog collection, “Woodworking with Robots,” to share some of the more digital sides of woodworking on the site. While the information might not be for everyone, there is a place for it in many woodshops and we’re excited to start covering it here!

|

CNC is Knocking on Your Shop Door. Will You Answer? |

|

Where CNC meets handwork: Owain Harris |

|

Hand-routed lettering |

Recommended for beginners

Creality Ender-3 3d printer

- Printable area of 220mm by 220mm or about 8 1/2 in. by 8 1/2 in.

- Great starter printer for those who aren't sure how far down the 3d printing rabbit hole they want to go.

Author recommended

Matter Hackers MH Build Series PLA Filament

Comments

I look forward to more, Ben.

Hey Ben - Interested in the potential of 3D printing and like that $200 cost of entry. I am quite adept using Sketchup (and recently upgraded to the Pro version) on an Apple computer. Can you use files created in Sketchup Pro for 3D printing on that one you linked to?

Yes! Sadly, only sketchup pro I hear. That prices me out, so I mostly use Fusion 360, but I have heard you can export STL files from SketchUp just fine. Once you have an STL file, you'll need to load into a slicer program (I use Cura, which is free) and that makes the file you load into the printer.

Great - thanks for that. I tried switching over to Fusion 360 when I got a Shaper Origin (luckily paid for from income from client's woodworking projects) but found the learning curve too steep. Glad to hear I can likely stick with Sketchup!

“[Deleted]”

I've been reading through old issues of FWW and when it shifted to color, someone wrote in complaining about the change. This feels similar. Technology will never stop evolving the craft, so let's consider ways to adapt and integrate! More please!

Hi, Ben — I'm looking forward to more like this. I have a 3D printer in my small hobby workshop and found it incredibly useful and versatile for everything from jigs and templates to shower curtain hooks and a wiring harness clip for a friend's car. In my view, it's just another tool — it doesn't replace the woodworker, but rather, enhances what that woodworker can achieve.

I use my 3D printer to make numerous shop items, from custom chuck faces to jigs to hold downs. I updated my Ender 3 Pro with an extruder/hotend from Micro-Swiss and customized Marlin firmware so that I could print carbon-filled filaments including nylon and carbon, which are much stronger than PLA and last a long time in the shop. Items consisting of segmented parts held together by metal screws can easily be made via the use of heat-set thread inserts from McMaster-Carr.

I use the free open source software FreeCAD for my CAD designs, export them as STL files, which I then 'slice' for my 3D printer using Ultimaker's Cura software (also free).

I do find that filaments need to be kept dry (their hygroscopic) for making quality prints, so I dry the filament then store them in o-ring sealed Home Depot buckets along with desiccant. And I operate my printer in a homemade air-tight plywood enclosure, also with desiccant.

So I fully agree w/ Ben than woodworking and 3D printing are natural partners.

My printer really is one of the most useful tools in my shop for all sorts of things that Ben mentioned. One of the best has been designing and printing universal dust port adaptors for my variety of small power tools. All my small tools, including my Festools, have a simple twist lock connection so there’s no wasted time with adaptors or various hoses.

I would love to see a pic of that! Super cool concept. If you're so inclined, [email protected]

Log in or create an account to post a comment.

Sign up Log in