STL284: Wood moves, and the other woodworkers are wrong

Gary Rogowski joins Mike and Ben to discuss knockdown joinery ideas, steam bending, wood movement and what to do with your stuff when you dieClick here to find out more about Dave Richards’ SketchUp for Furniture Design

Drawing On The Right Side of the Brain by Betty Edwards

Now I Sit Me Down: From Klismos to Plastic Chair: A Natural History by Witold Rybczynski

Gary’s Podcast: Creativity: Hustlers Fakers and Thieves

Question 1:

From Bruce:

I’ve searched for years for traditional knockdown joinery details for wardrobes and the larger schranks. It has been hard to find any sufficient details to build this type of furniture with sliding /locking joinery using wedges and other locking joinery. Where can traditional joinery be researched since museums in the area where I live don’t have many examples and all requests to the docent have been declined when I inquired about asking for pieces to be opened for interior viewing/ inspection.

|

Knockdown armoireSkeleton-and-skin construction is adaptable to a range of styles |

Classic Joints with Power Tools by Yeung Chan

Chinese Domestic Furniture in Photographs and Measured Drawings by Gustav Ecke

Question 2:

From Rob:

I have another discussion point that may be of interest, and I cannot recall you discussing this before – it came up in the FWW forum this time – what to do with the collection of tools when you die or become unable to use them. The old trope of the partner selling them for what I told her I paid for them holds true, but it seems some users sort of expect their collections to be used together in the future and others like me are unconcerned.

There are a number of interesting perspectives on the forum as discussion points, and I would enjoy hearing your take on the issue.

Segments:

Gary – Technique, steam bending

Mike – Technique, tapping wood

Ben-Favorite tool, files

|

Bending Wood With Hot WaterRuss Filbeck doesn’t use a steambox when bending wood for his ladderback chairs. Instead, he uses a copper tray made by noted Shaker box maker John Wilson. |

|

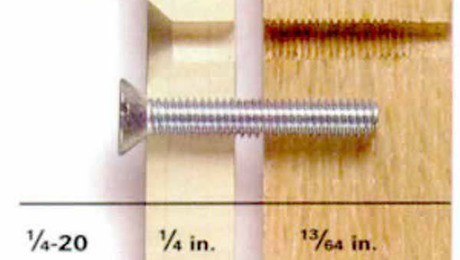

Threading Wood for Machine ScrewsCut durable threads in wood with metal taps |

|

Files, Rasps, and RifflersMario Rodriguez provides a guide to files, rasps, and other effective but underappreciated shaping tools. |

Question 3:

From Joe:

I’ve heard you discuss the flattening of sharpening stones, but have never heard you talk about technique. Probably because it’s so simple to do and obviously important. I have a stand-alone shop with no running water. I have been bringing my water stones into my house to flatten. As you can imagine this is a major pain in the ass. This basically results in me not flattening the stones as often as I should. Do you have any suggestions on stone flattening in a shop without running water?

Question 4:

From Ed:

From Ed:

I want to build a tv stand that looks similar to another piece of furniture. The lower shelf will have a section that is constrained by the legs so I think I need to leave room for the shelf to expand and contract. But the existing piece doesn’t have space built in and has not had any problem since I bought it over 10 years ago. Am I overthinking this?

Should I just glue the bottom front rail to the front of the shelf and let the rest of the self “float” on the side and back rail? Or will it be okay to leave no room for expansion between the legs and glue the shelf to the front, rear, and side rails?

|

Add a Shelf to a TableFour attractive ways to handle wood movement in a solid-wood shelf |

Every two weeks, a team of Fine Woodworking staffers answers questions from readers on Shop Talk Live, Fine Woodworking‘s biweekly podcast. Send your woodworking questions to shoptalk@taunton.com for consideration in the regular broadcast! Our continued existence relies upon listener support. So if you enjoy the show, be sure to leave us a five-star rating and maybe even a nice comment on our iTunes page.

Comments

Bruce, you should check out the Andrew Hunter article from 2017 on interlocking Chinese joinery.

I am happy to see Gary included in these discussions more often. While his experience and insight into woodworking topics is spot on, the wealth of information on other relatable subjects is unmatched.

Log in or create an account to post a comment.

Sign up Log in