STL288: Never met a vise he didn’t like

Mike, Vic, and Ben discuss Vic's upcoming move (again), design classes, the features they'd want in a bandsaw, and what vises make them happiest.Furniture Design For Woodworkers with Mike Pekovich

COURSE BEGINS APRIL 26, 2023

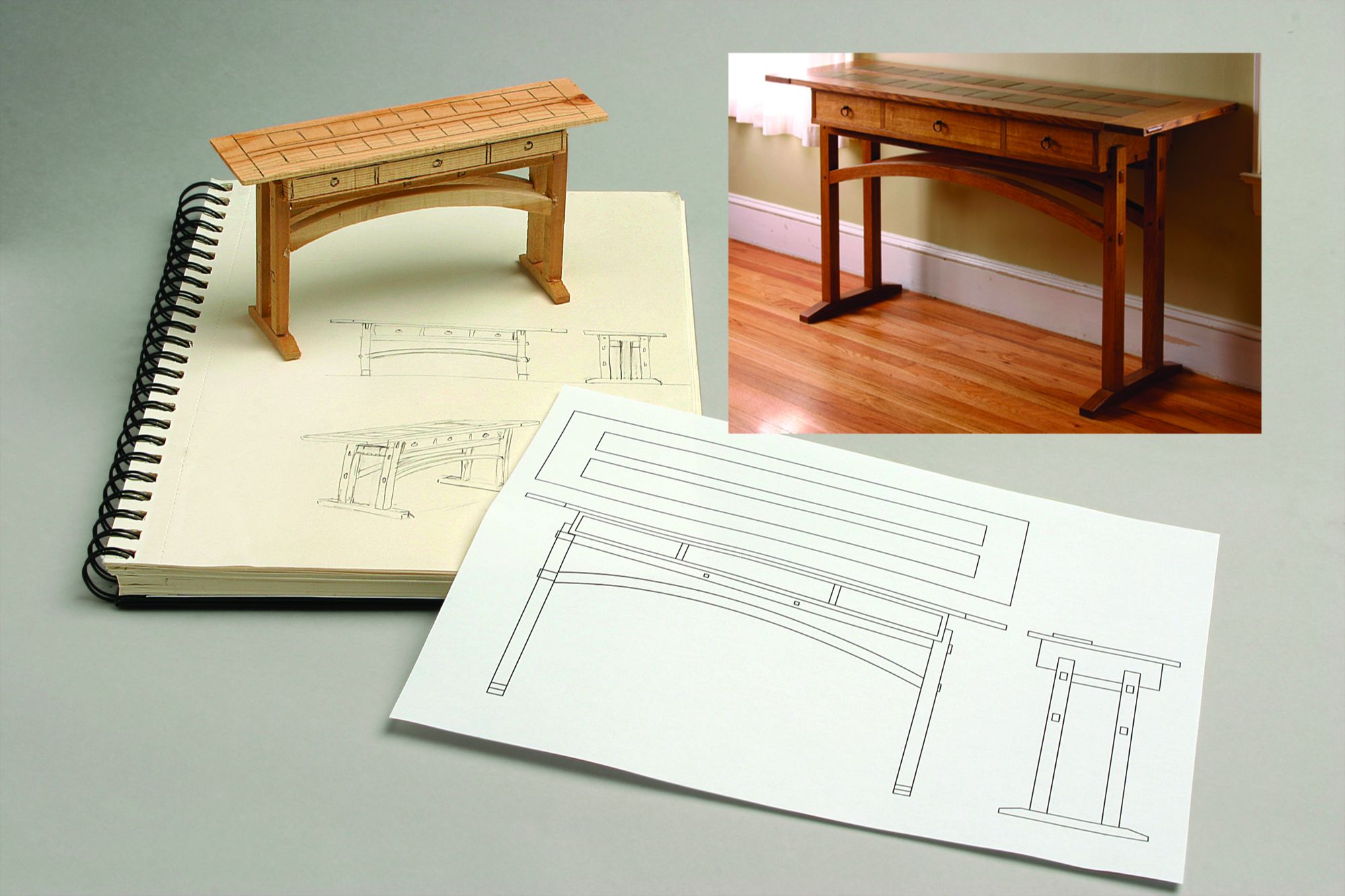

Learn how to develop a reliable and rewarding design process while creating a collection of personal, one-of-a kind furniture designs that are ready to build.

Learn how to develop a reliable and rewarding design process while creating a collection of personal, one-of-a kind furniture designs that are ready to build.

6+ hours of in-depth video lessons

Exclusive community forum

Live Q&A sessions with Mike

Guided development work to improve at every milestone. Click here for more information.

Question 1:

From Bob:

I’m about ready to buy a bandsaw. If you had the choice, would you start out with a 14-inch saw, or buy something bigger right away. If something bigger, how big? I want it to cut curves and for resawing. My only machines now are a table saw and a drill press.

|

What to Look for When You Buy a BandsawLearn how to evaluate bandsaw models before you close the deal. |

|

Tool Test: 14-in. BandsawsGreat for curves and for resawing, these saws are the perfect fit for a home shop |

|

STL 130: Workbench advice and waterfall joineryBench tips for a fledgling woodworker. Plus a call for help, an update on SawStop vs. Bosch, and our all-time favorite furniture and tools. |

|

STL 131: Leg vise lowdown and favorite techniquesPlus the guys talk about keeping stains off workpieces, drill-press mortising attachments, grain direction on tabletops, and Ben makes everyone squirm with one of his favorites. |

Every two weeks, a team of Fine Woodworking staffers answers questions from readers on Shop Talk Live, Fine Woodworking‘s biweekly podcast. Send your woodworking questions to shoptalk@taunton.com for consideration in the regular broadcast! Our continued existence relies upon listener support. So if you enjoy the show, be sure to leave us a five-star rating and maybe even a nice comment on our iTunes page.

Comments

Any information on what bandsaws have decent dust collection. My 14 inch Rockwell Delta completely fills my shop instantly with dust. I've tried lots of gadgets to try to trap it--none of them work. Is there a saw that has solved the problem?

When I first started watching, I thought Ben finally organized his shop. Then he said he was in the FW shop.

You're entirely confusing organized and clean! My shop is more organised than 99% of the shops I've been in. Clean on the other hand... !

Thanks for answering my band saw question. Now I feel bad about my previous comment about Ben's shop.

I have the exact same bandsaw as Ben does and agree with his assessment of it. I'd love to have found a nice vintage delta and cleaned it up, but by the time it was set up and ready it would've cost as much or more than the Grizzly. Anyway, hearing the discussion of it again in this episode reminded me of some upgrades I've made, one inspired by Ben in a previous STL and another that more people might want to explore.

Ben mentioned he 3D printed an upper dust collector I realized that I needed to do the same. Thanks for the tip! I also replaced the factory tension spring with a replacement from Carter and got an EZTensioner, both have really helped with cut quality. I do have the riser block installed, not sure if the factory spring would've performed better without that. Small thing: I hardwired one of those little magentic led lamps so it is always ready to go when the bandsaw is plugged in (bonus! they're rated 110-250 volts, so I was able to hardwire it even with the bandsaw wired for 220).

I bought a 1/4" blade when I bought the saw and I've never even taken it out of the box. The 1/2" blade is all I ever use, but I wasn't very happy with the amount of twist or deflection I was getting with the stock roller guides. Rather than replacing them, I just bought wider bearings (8x22x11 vs 8x22x7). I got a sack of them off on online auction site for cheap. They fit with no modifications except longer bolts and the range of adjustment accommodates the extra width. It would be a huge pain now to switch to a narrower blade though, since I'd have to swap the bearings as well, but I'll just buy another bandsaw if that ever comes up.

I'm considering adapting this post as a novel, if anybody is interested in picking up the publishing rights.

Laughter is good for the soul. Enjoyed the show.

I enjoyed the discussion about vises. I, too, was enamored with Benchcrafted vises, but my workbench is trestle-style. In fact, the only good thing about it is that the apron pieces are bolted on using threaded inserts. I removed two segments of one long apron, and attached two "legs," using height adjusters to make up for any floor unevenness. Now, I've got a Benchcrafted leg vise, which I love, and a sliding deadman which I never expect to use.

Two comments, laughter meter is great, just leave it unplugged so the needle stays on zero : )

When are you guys going to do FWW Live again? I finally have the time to go and now it's gone...

Keep up the good work and thank you.

Enjoy the shows. Commission projects: I can do that. Then how am I going to do that? Finally, why did I say I could that!! From the last STL on wood, I have made furniture out of locust, cabinet out of box elder, lamp stand out f sycamore, currently finishing a table top out of ambrosia maple. I had some hop hornbeam but not enough to do anything with it.

Thought I'd let you guys know I did by the Laguna 14 12 bandsaw. However the assembly instructions leave something to be desired. They said to assemble the base with the "fixings" provided. Didn't say which "fixings" Not a big deal, but also not very professional. Same way with fastening the saw to the base. I also never saw a list of "fixings" in the manual.

Log in or create an account to post a comment.

Sign up Log in